Oil pollution clearing device for mechanical equipment

A technology of mechanical equipment and cleaning device, applied in lighting and heating equipment, dryer, drying gas arrangement, etc., can solve the problems of inconvenient adjustment of the distance between the bristles and the cleaning handpiece, affecting the use effect, and inconvenience in taking out sewage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

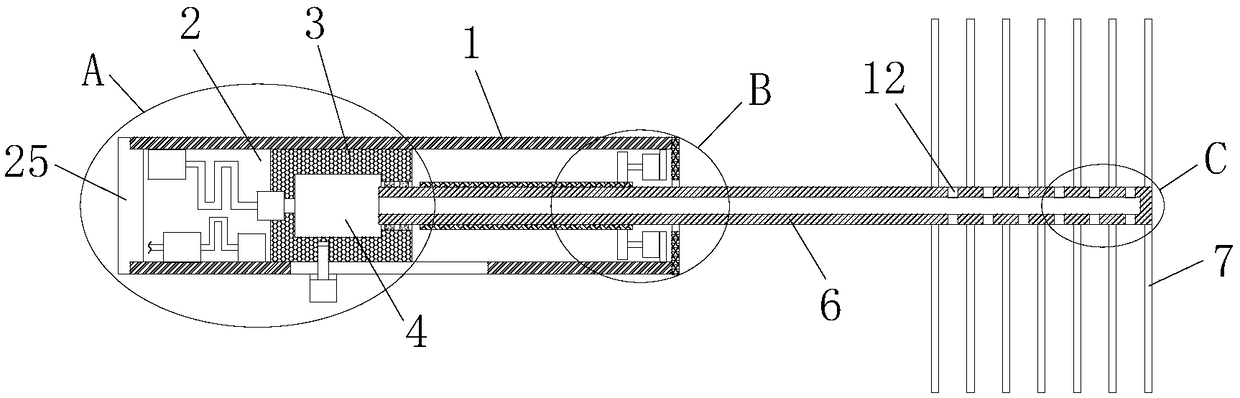

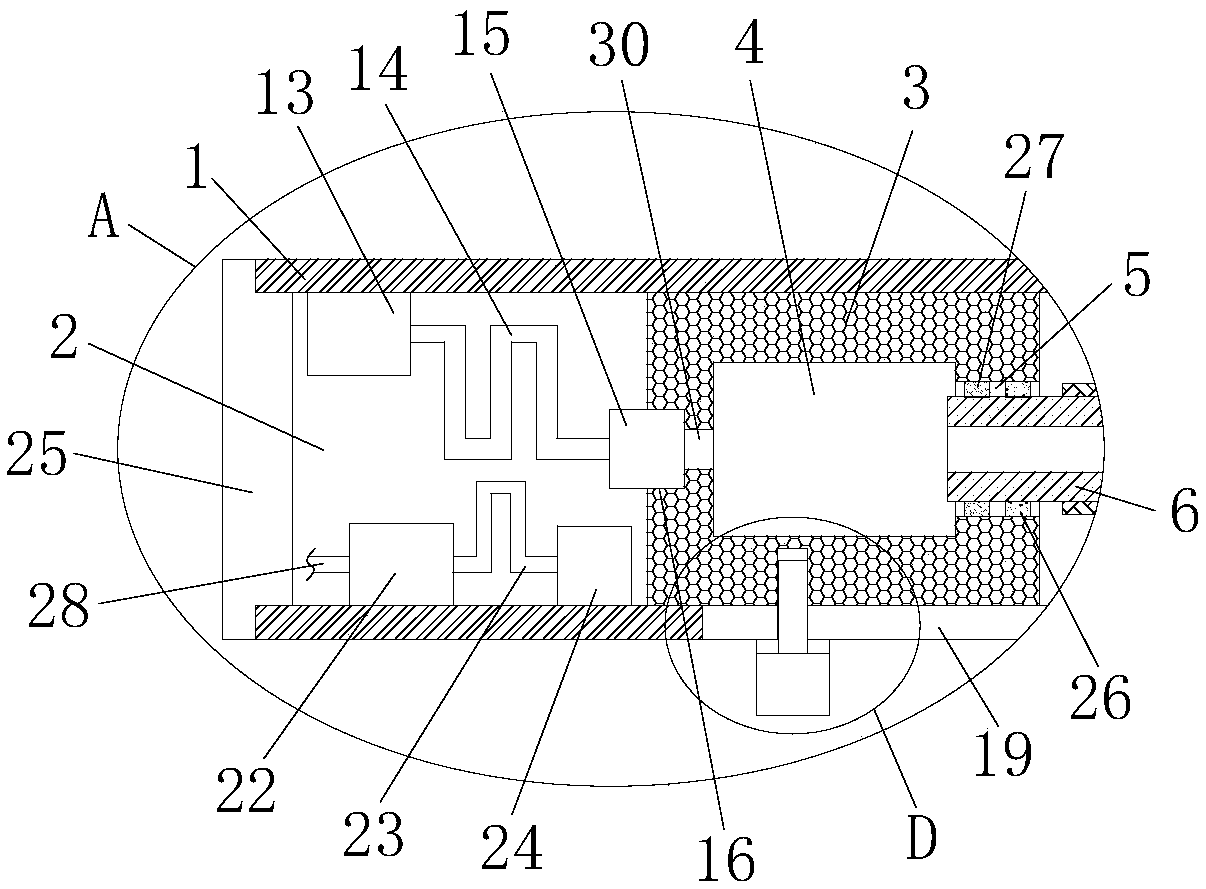

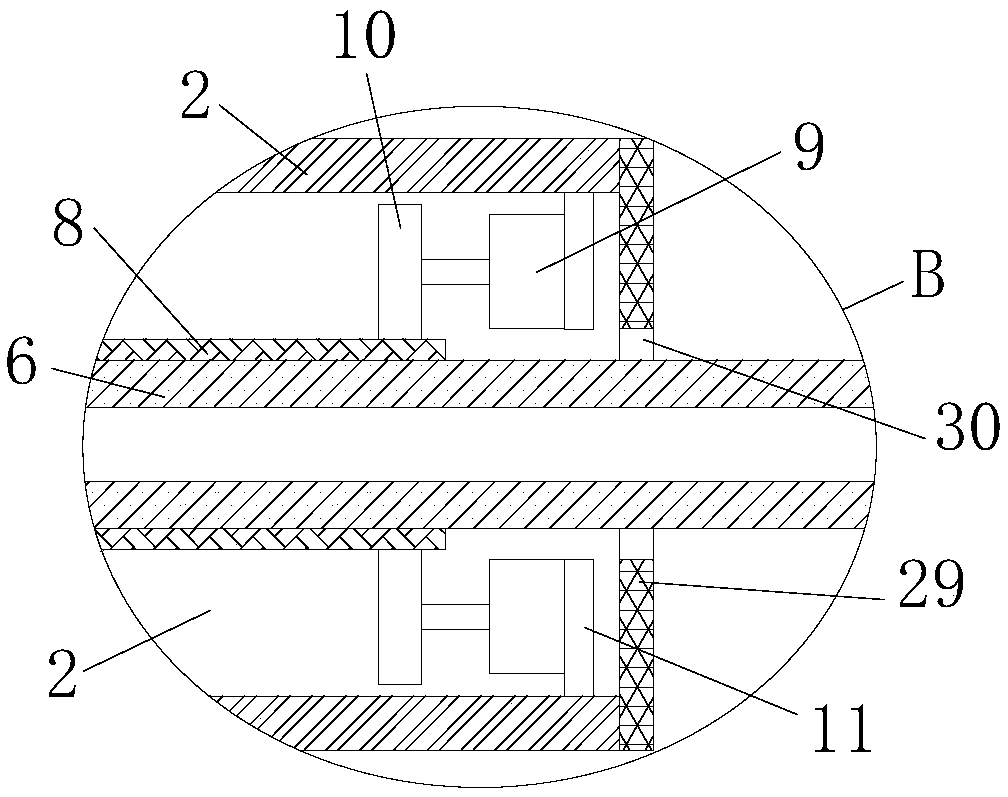

[0027] refer to Figure 1-5In this embodiment, a device for cleaning oil from mechanical equipment is proposed, which includes a handle 1, a through hole 2 is provided at one end of the handle 1, an air box 3 is slidably installed in the through hole 2, and a chamber 4 is provided on the air box 3. One side of the inner wall of the chamber 4 is provided with a rotating hole 5, and a sleeve 6 is rotated in the rotating hole 5, and one end of the sleeve 6 extends to the outside of the handle 1 and is set in a closed state, and the outside of the sleeve 6 is fixedly installed. There are a plurality of bristles 7, and the inner wall of the casing 6 is provided with a plurality of communication holes 12, and the top inner wall and the bottom inner wall of the through hole 2 are welded with a mounting rod 11, and a motor 9 is fixedly installed on one side of the mounting rod 11. A gear 10 is fixedly installed on the output shaft of 9, a rack 8 is arranged on the outside of the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com