Automatic riveting device for connector

A riveting device and connector technology, which is applied in the manufacture of vehicle connectors, contact boxes/bases, etc., can solve problems such as increased waiting, transmission delay time, high requirements for installation and matching accuracy, and fatigue, and reduce manual operations. Effect of Strength and Labor Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to describe in detail the technical content, structural features, achieved goals and effects of an automatic riveting device for connectors of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

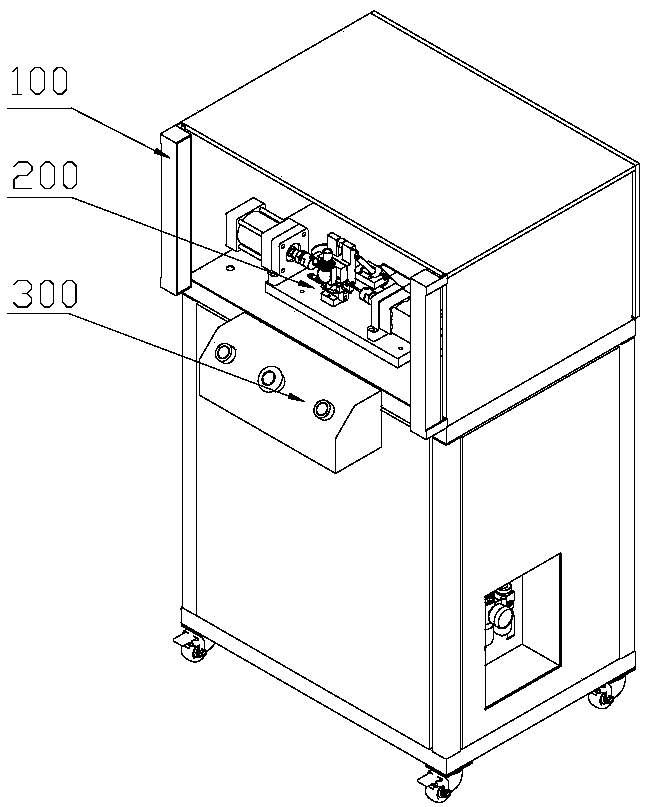

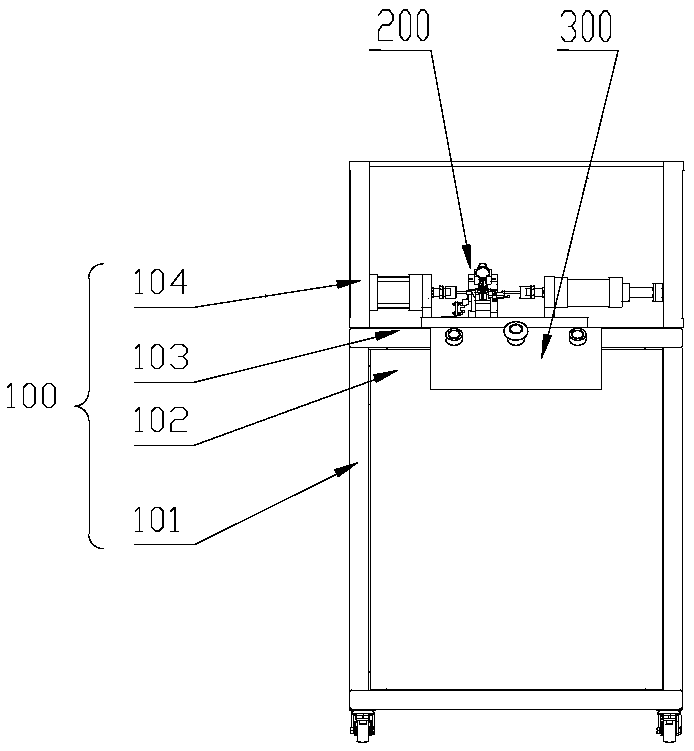

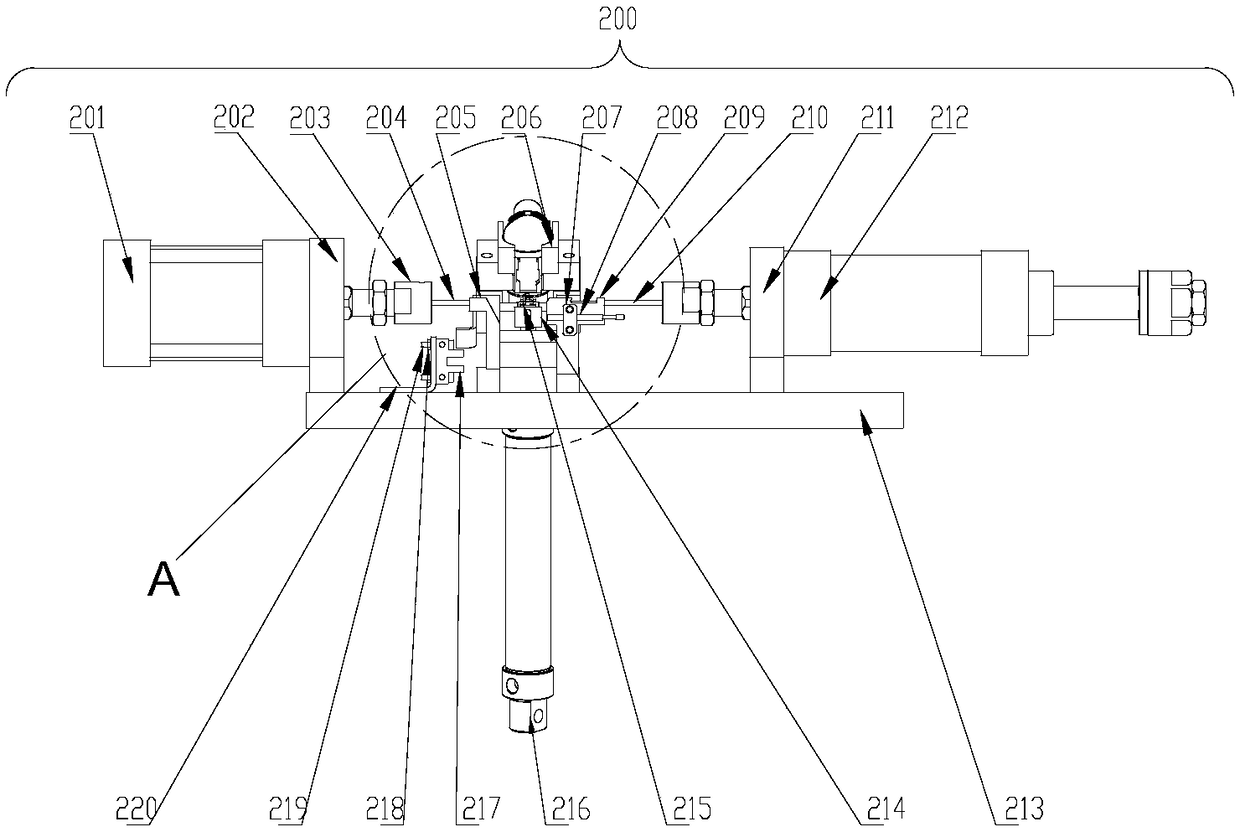

[0051] Such as Figure 1 to Figure 9 As shown, an embodiment of an automatic riveting device for connectors of the present invention is disclosed, including: a frame 100, an automatic riveting mechanism 200, and an operation control mechanism 300; The automatic riveting mechanism 200 is surrounded by the cover plate 102 of the frame 100 ; the button shell 301 of the operation control mechanism 300 is welded to the frame 100 .

[0052] Wherein, the rack 100 further includes: a frame body 101, a cover plate 102, a support plate 103, and a grating post 104; the frame body 101 fastens and connects the cover plate 102, the support plate 103, and the grating post 104 into a whole by screws.

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com