A method for manufacturing iron-based amorphous sensor probes by laser melting stereoforming

A technology of sensor probe and three-dimensional molding, which is applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of high cooling rate, etc., and achieve excellent soft magnetic properties, great theoretical value and potential economic benefits, reduce Effect of small excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

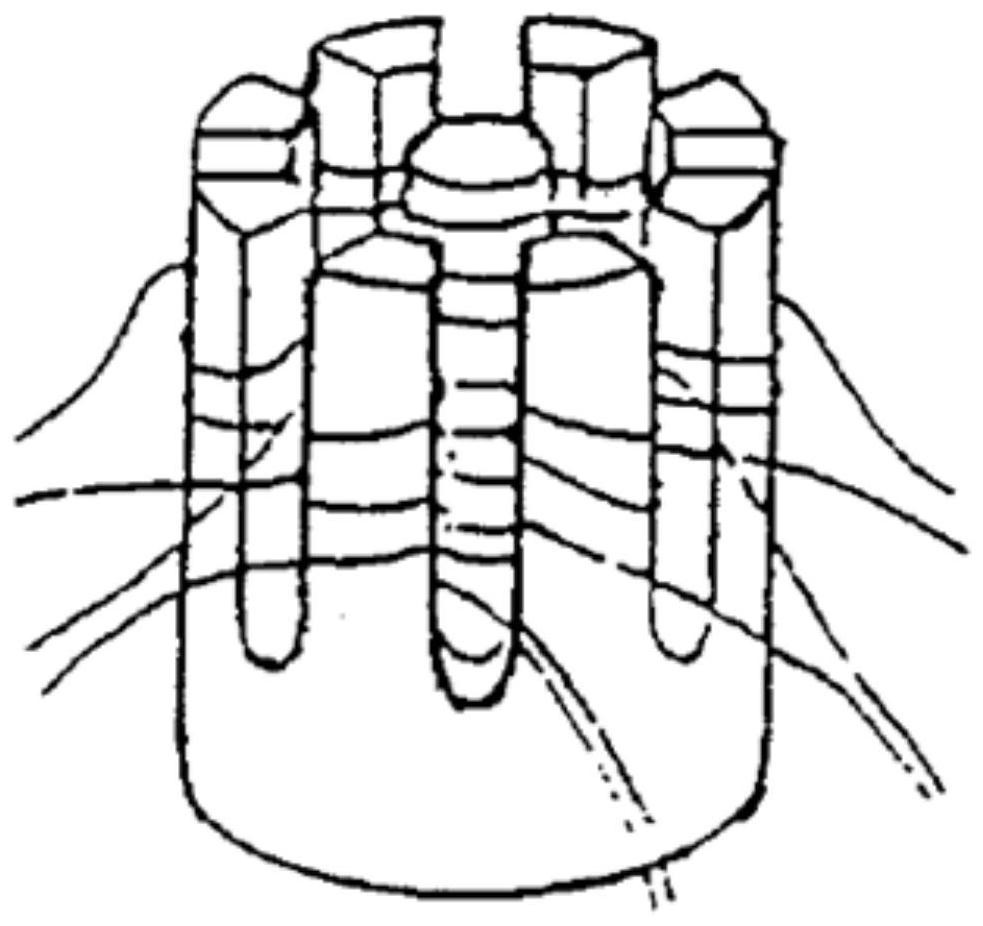

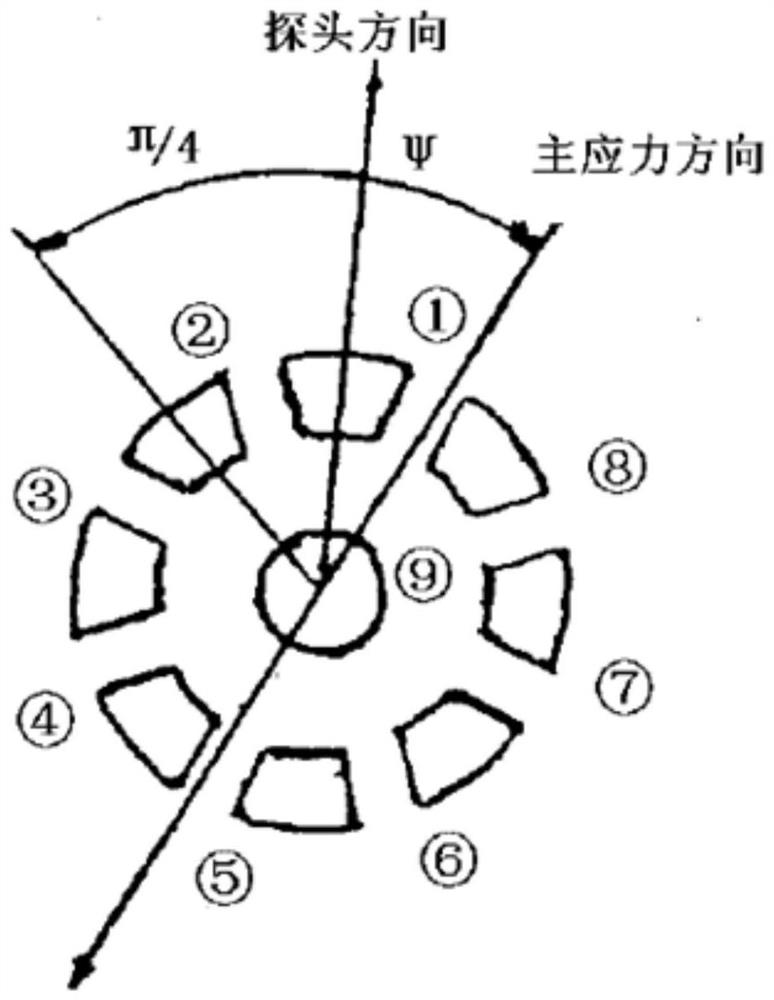

[0031] A kind of laser melting three-dimensional molding method of the present invention makes iron-based amorphous sensor probe, comprises the following steps:

[0032] Step 1, preparation of alloy ingot: the chemical formula of iron-based amorphous alloy is Fe 36 co 36 Si 4 B 20 Nb 4 , converted from atomic percentage to mass percentage; use high-purity raw materials Fe, Co, Si, B, Nb, weigh each raw material according to the composition of the iron-based amorphous alloy, and then put each raw material into a high-temperature furnace prepared in advance , in the presence of protective gas, the alloy is repeatedly smelted at high temperature to prepare a master alloy ingot; wherein, the protective gas includes one or a mixture of argon, nitrogen, etc.; the purity of the protective gas requires a volume percentage greater than 98% ;

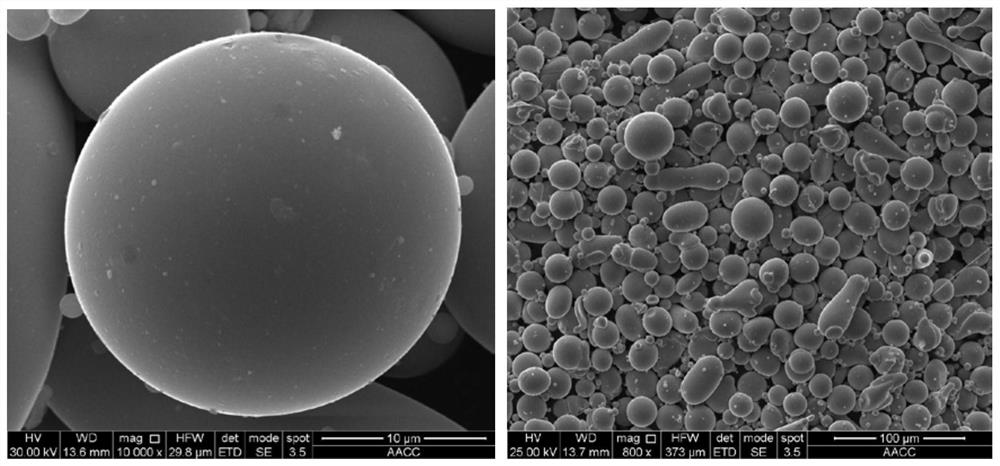

[0033] Step 2, using gas ato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com