Projection welding screw chuck structure

A technology of screw and collet, which is applied in the field of new projection welding screw collet structure, which can solve the problems of large flange, inability to open the opening angle of spring collet, small diameter of projection welding screw, etc., to achieve reliable positioning and convenient processing , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

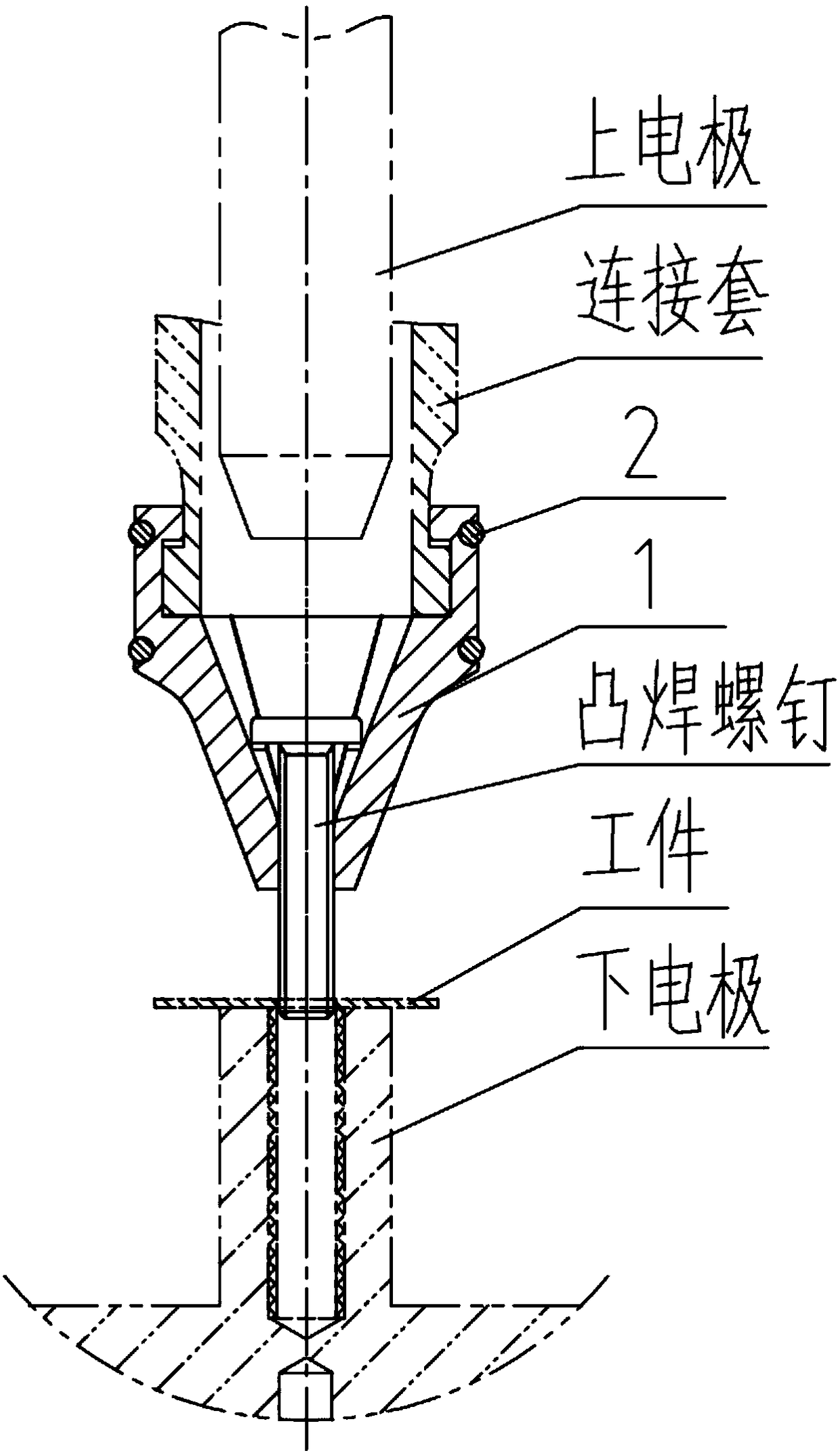

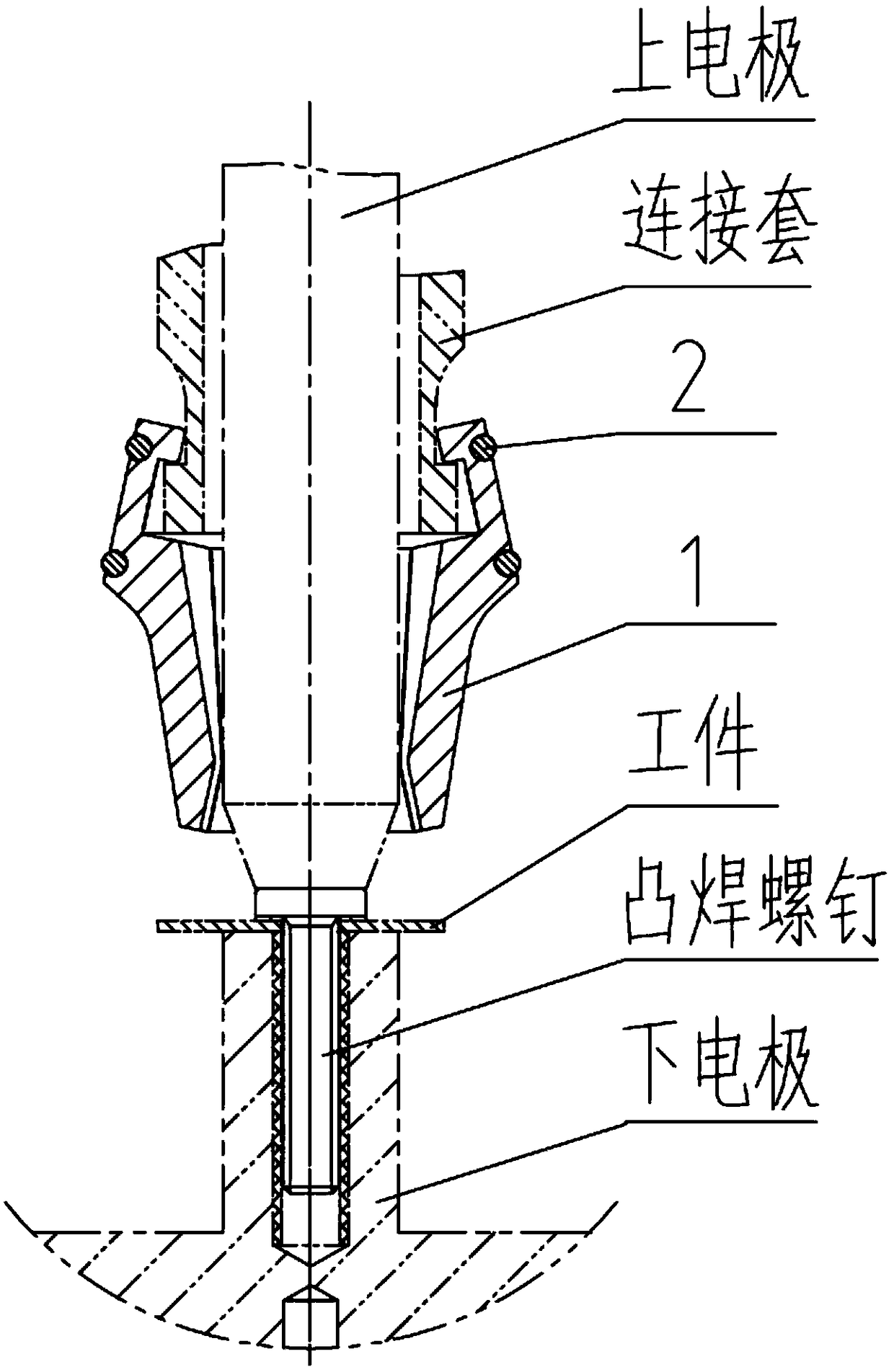

[0011] The novel of the present invention will be further described below according to the accompanying drawings.

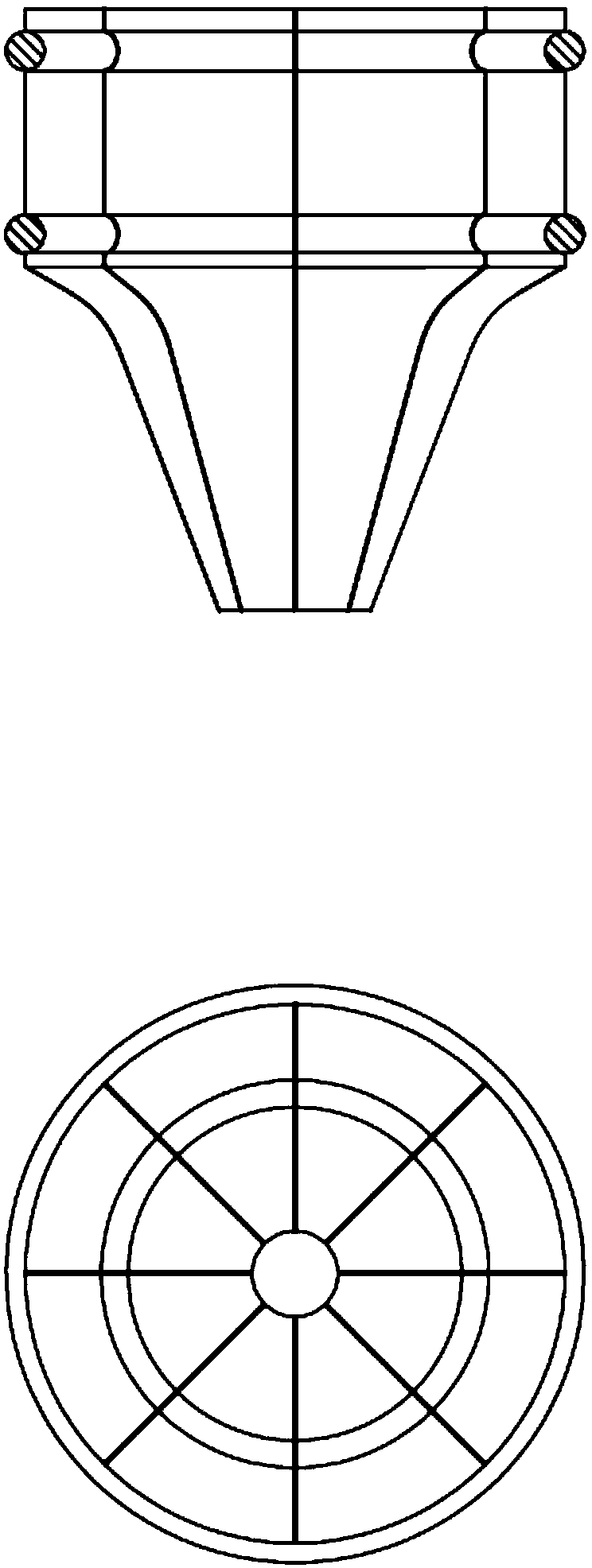

[0012] The projection welding screw chuck (1) is set to be evenly distributed into eight equal parts, and the inside is provided with a stepped tapered hole, and the outer diameter is provided with two annular grooves that can be loaded with annular springs.

[0013] The projection welding screw chuck (1) and the connecting sleeve can be connected by two annular springs (2), and the projection welding screw can enter the interior of the projection welding screw chuck (1) from the side, and then directly enter the middle hole of the workpiece and the lower electrode After the middle hole is positioned and the projection welding screw is positioned, the upper electrode goes down, and the end surface of the upper electrode is fitted with the end surface of the projection welding screw to drive the projection welding screw to go down, and at the same time overcome the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com