Substation inspection robot camera anti-collision system

A technology for inspection robots and cameras, applied in manipulators, manufacturing tools, etc., can solve the problems of camera lens damage and lack of protection, and achieve the effect of stable machine operation, convenient disassembly and connection, and a wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

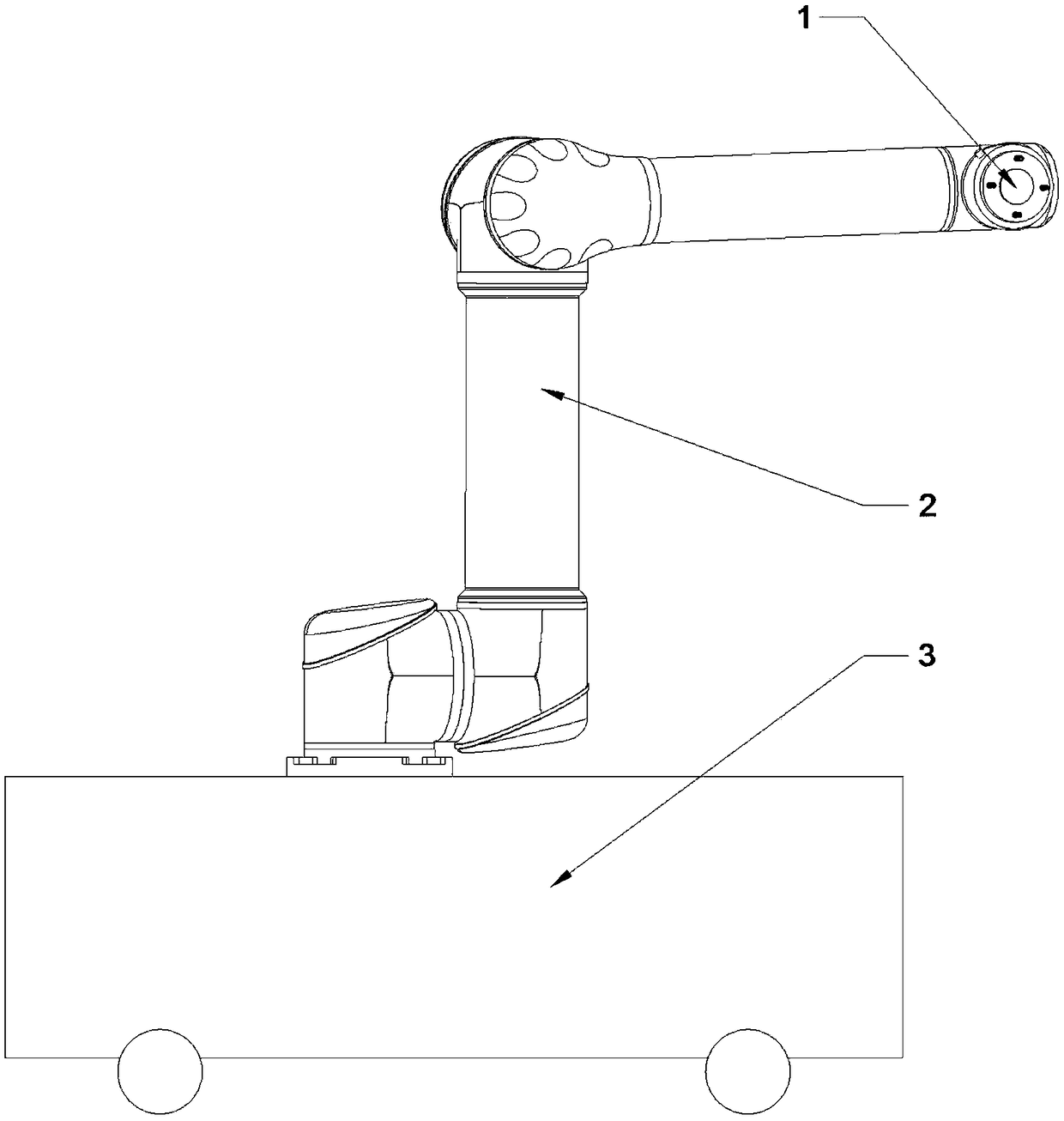

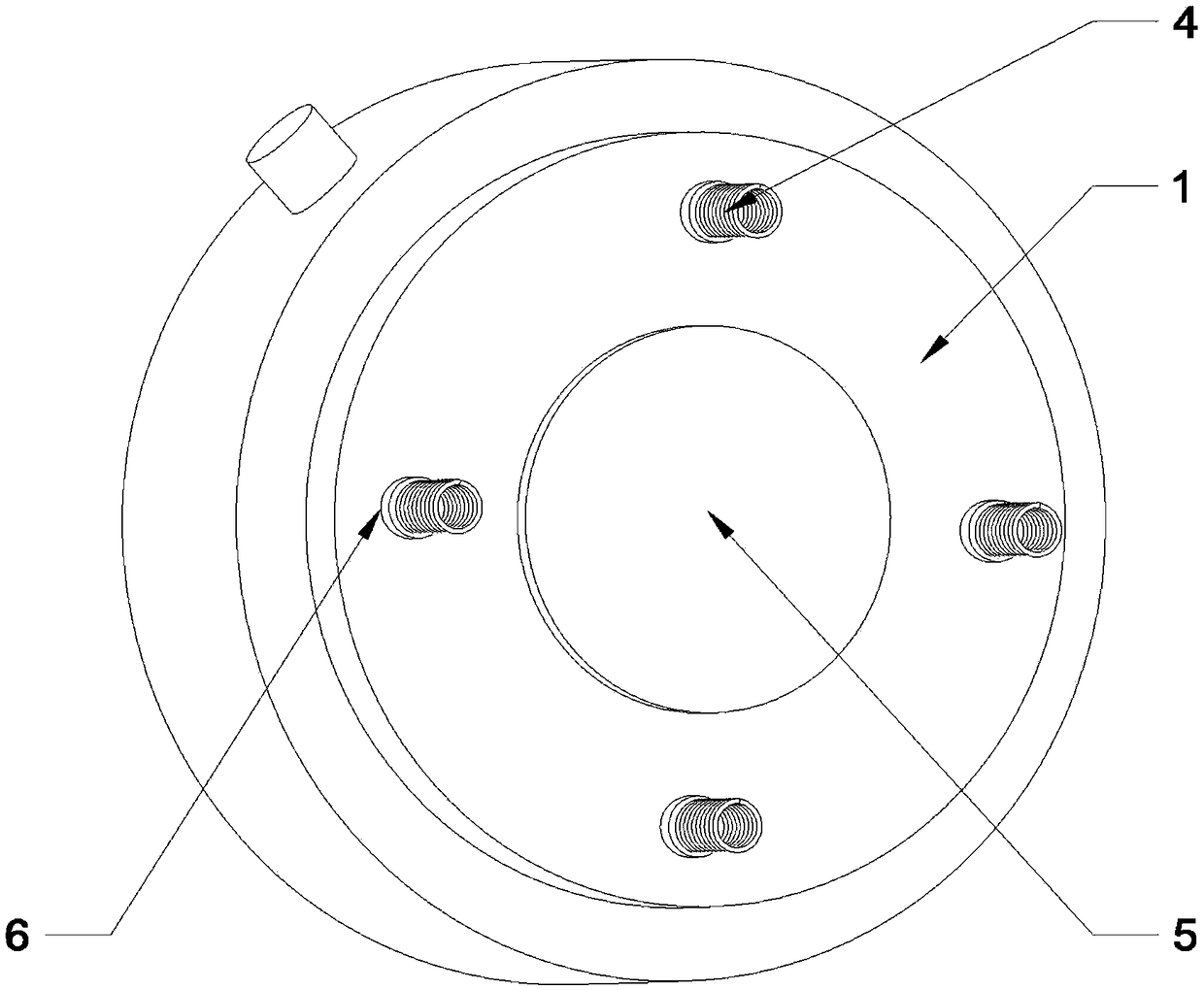

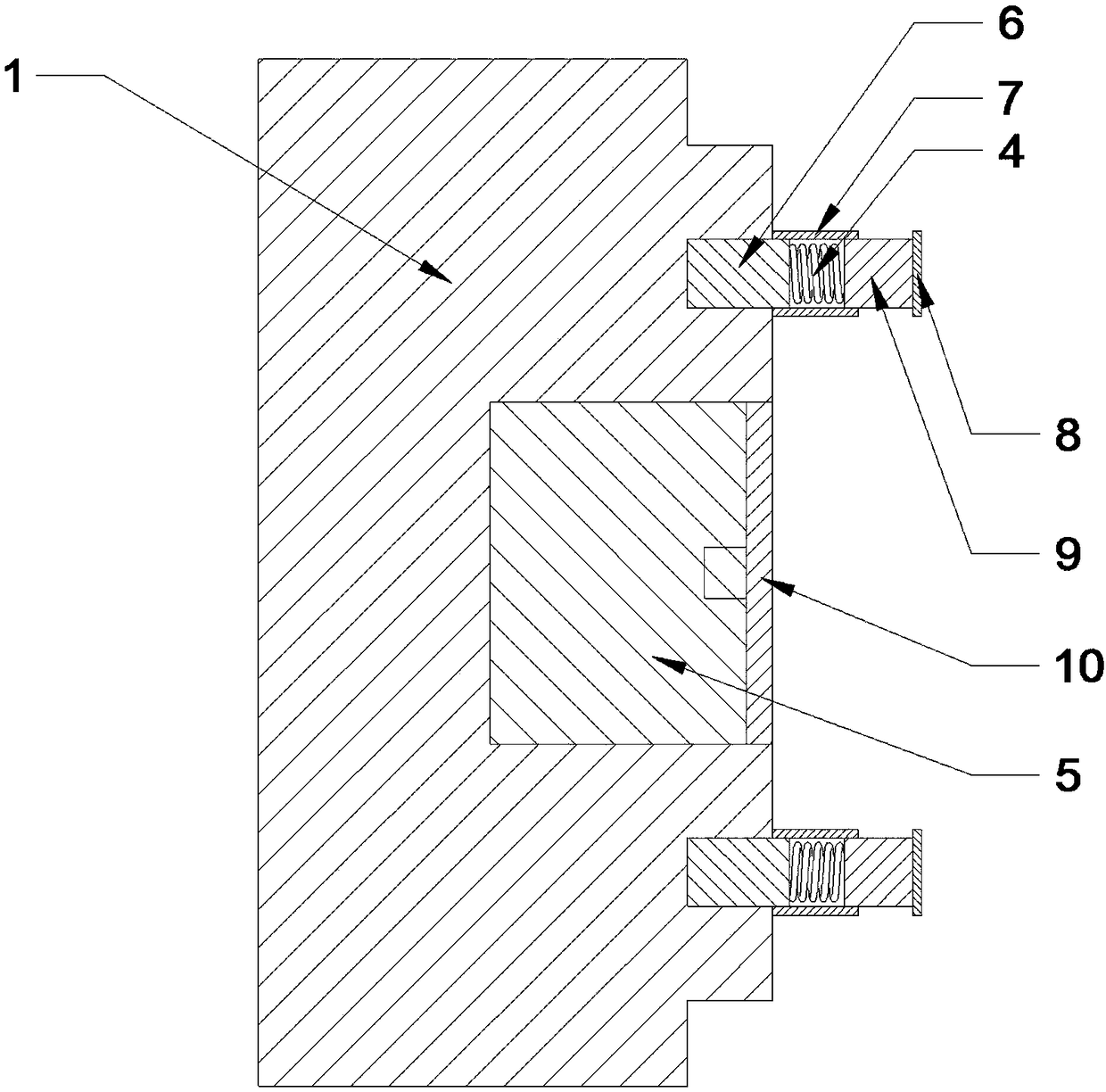

[0028] See Figure 1~3 , An anti-collision system for a substation inspection robot camera, including a robot body 3, a robot arm 2, a camera 5, a robot arm gear motor and a gear motor controller. The bottom end of the robot arm 2 is connected to the upper surface of the robot body 3, and the robot arm 2 The end is equipped with an end effector 1: a camera 5 is installed on the end effector 1, and a plurality of springs 4 are arranged on the surface of the end effector 1; the end of the spring 4 is fixed on the pressure sensor 6 provided on the end effector 1, and the pressure sensor 6 It is connected with a signal conditioning transmitter, the signal conditioning transmitter is connected with a geared motor controller, and the geared motor controller is connected with a mechanical arm geared motor.

[0029] In this example, when the inspection robot performs data collection, the robot body 3 moves to the vicinity of the data collection box, the robot arm 2 is positioned, the met...

Embodiment 2

[0031] See Figure 1~3 , An anti-collision system for a substation inspection robot camera, including a robot body 3, a robot arm 2, a camera 5, a robot arm gear motor and a gear motor controller. The bottom end of the robot arm 2 is connected to the upper surface of the robot body 3, and the robot arm 2 The end is equipped with an end effector 1: a camera 5 is installed on the end effector 1, and a plurality of springs 4 are arranged on the surface of the end effector 1; the end of the spring 4 is fixed on the pressure sensor 6 provided on the end effector 1, and the pressure sensor 6 It is connected with a signal conditioning transmitter, the signal conditioning transmitter is connected with a geared motor controller, and the geared motor controller is connected with a mechanical arm geared motor.

[0032] In this example, the end effector 1 is provided with a sleeve 7 on the surface, the spring 4 is sleeved in the sleeve 7, the front end of the spring 4 is connected to the rea...

Embodiment 3

[0038] See Figure 1~3 , An anti-collision system for a substation inspection robot camera, including a robot body 3, a robot arm 2, a camera 5, a robot arm gear motor and a gear motor controller. The bottom end of the robot arm 2 is connected to the upper surface of the robot body 3, and the robot arm 2 The end is provided with an end effector 1; the end effector 1 is equipped with a camera 5, and the surface of the end effector 1 is provided with a plurality of springs 4; the end of the spring 4 is fixed on the pressure sensor 6 provided on the end effector 1, the pressure sensor 6 It is connected with a signal conditioning transmitter, the signal conditioning transmitter is connected with a geared motor controller, and the geared motor controller is connected with a mechanical arm geared motor.

[0039] In this example, the number of springs 4 is at least four, and the springs 4 are equally spaced around the camera 5. The number of springs 4 is at least 4, and the springs 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com