A hinge-mounted independent suspension omni-directional mobile platform based on a McNum wheel

An independent suspension, omnidirectional movement technology, applied in suspension, motor vehicle, elastic suspension, etc., can solve the problems of increasing instability, production cost, not compact structure, complicated suspension part, etc. Reduced vibration amplitude and high load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

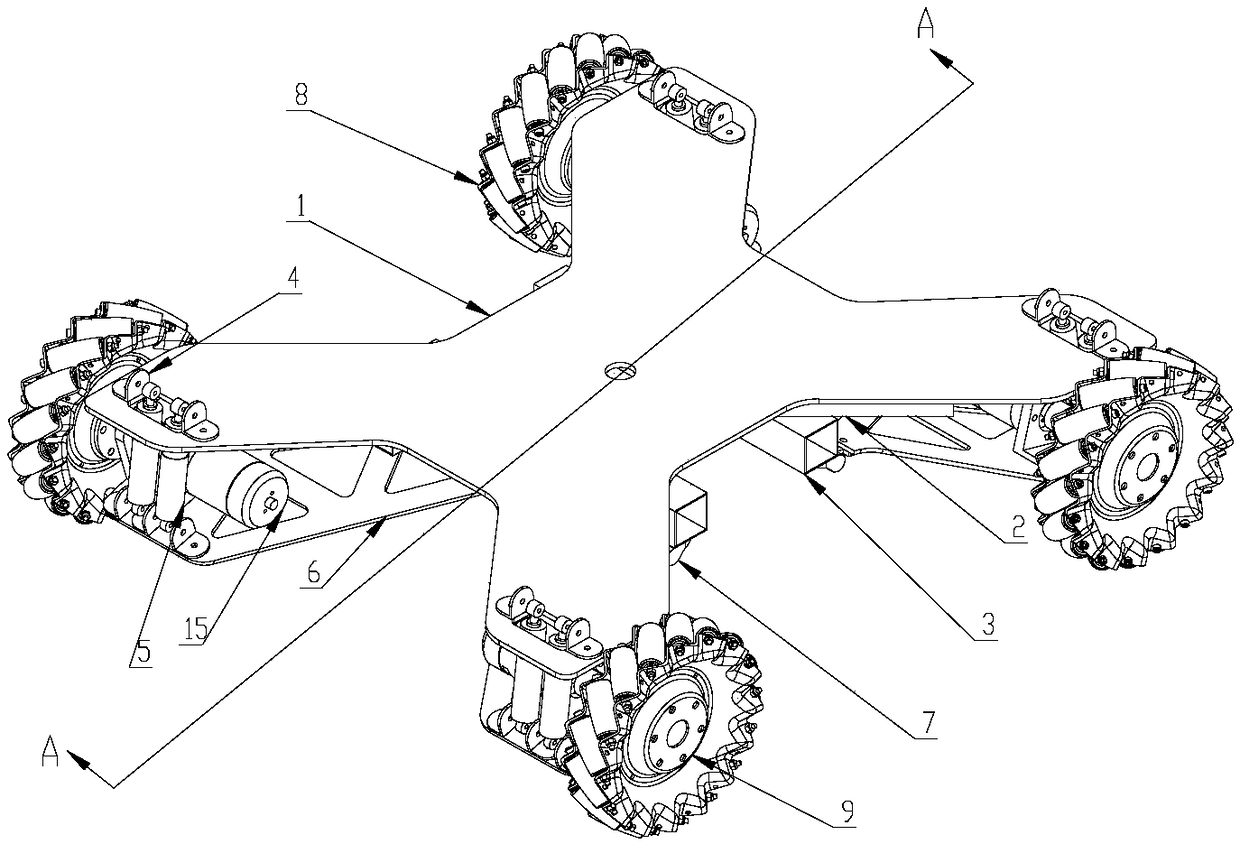

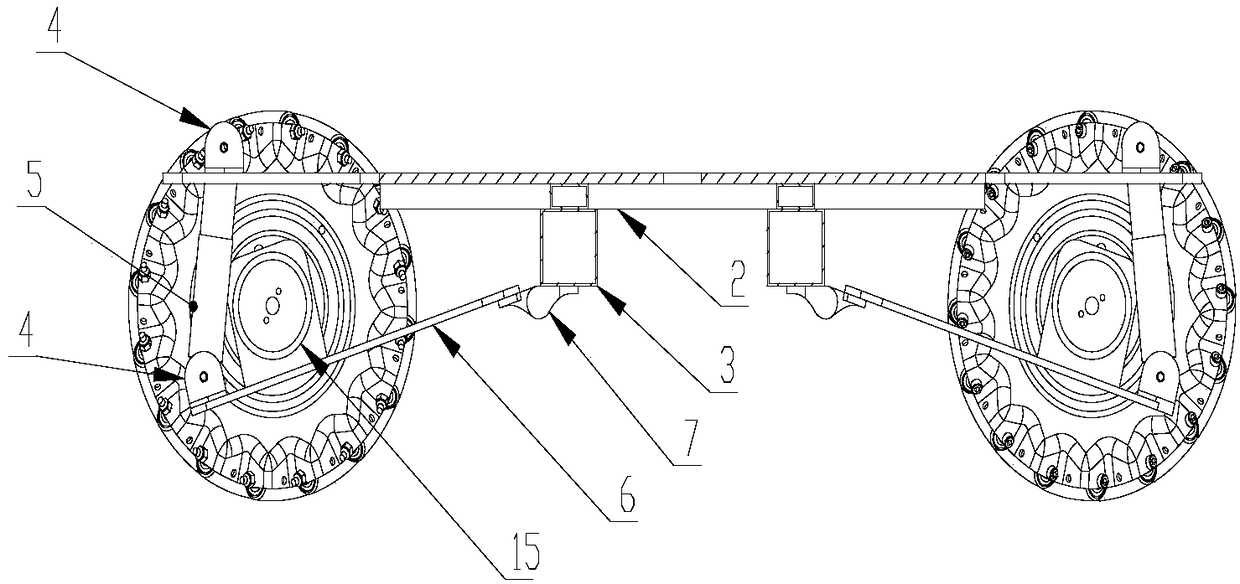

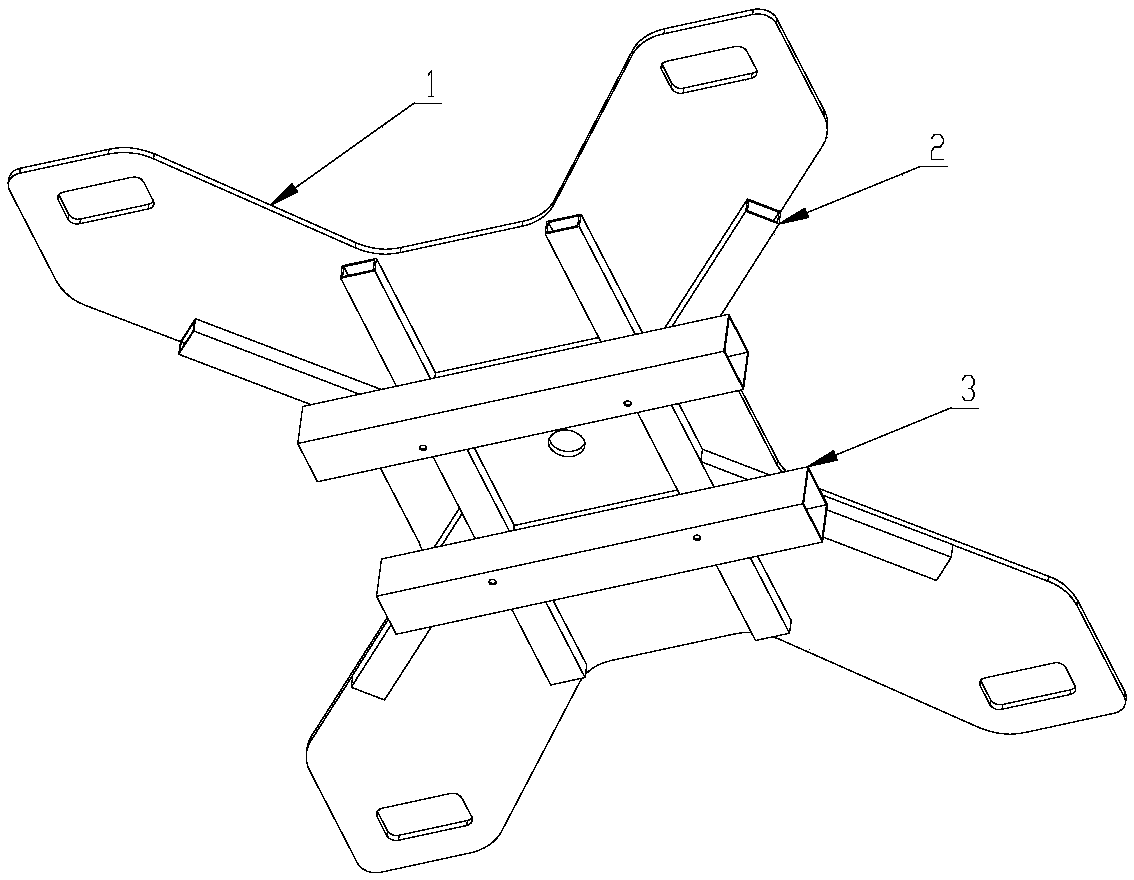

[0022] An omnidirectional mobile platform with independent suspension in the middle of the hinge based on mecanum wheels, including a bearing platform, an independent suspension mechanism, and a chassis wheel shaft mechanism. There are four independent suspension mechanisms and chassis axle mechanisms, and each independent suspension mechanism and chassis axle mechanism form a group, and the four independent suspension mechanisms and chassis axle mechanisms are respectively symmetrically arranged at the four corners of the bearing platform. The structures of the four sets of independent suspension mechanisms, the chassis axle mechanism, and the installation positions are mirror-symmetrical in front, rear, left, and right. Due to the omnidirectional mobility of the mecanum wheels and the symmetry of the front, rear, left and right suspensions, it can ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com