Multi-chain bucket sand mining and washing equipment

A technology for washing and sorting equipment and sand mining, which is applied in the direction of cleaning devices, conveyors, conveyor objects, etc., can solve the problems of low work efficiency, high cost, and soreness of human arms, so as to improve work efficiency, prevent blockage, reduce The Effect of Sand Mining and Transportation Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

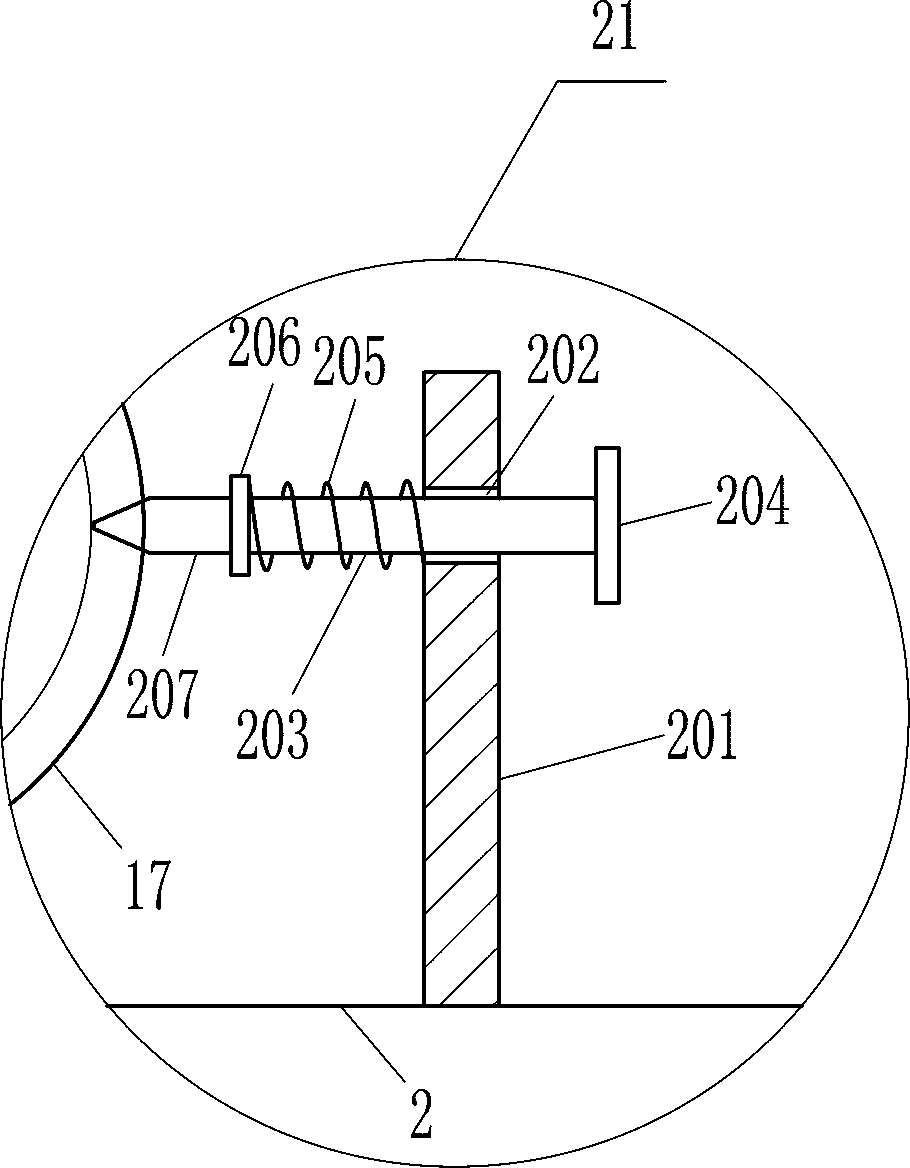

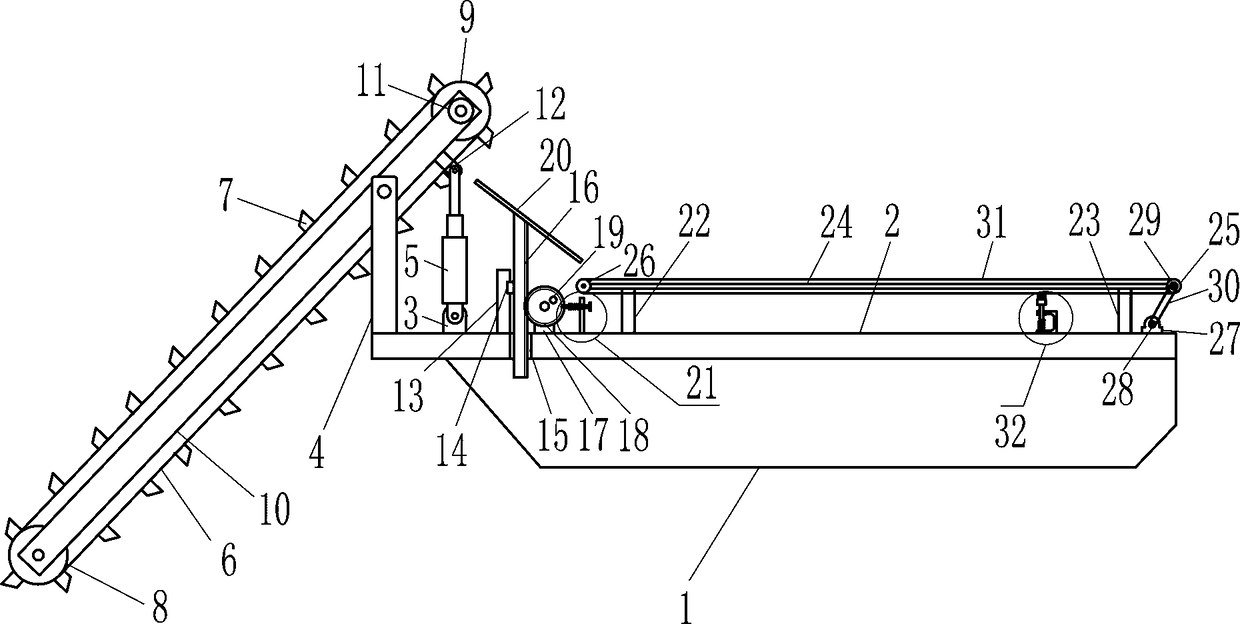

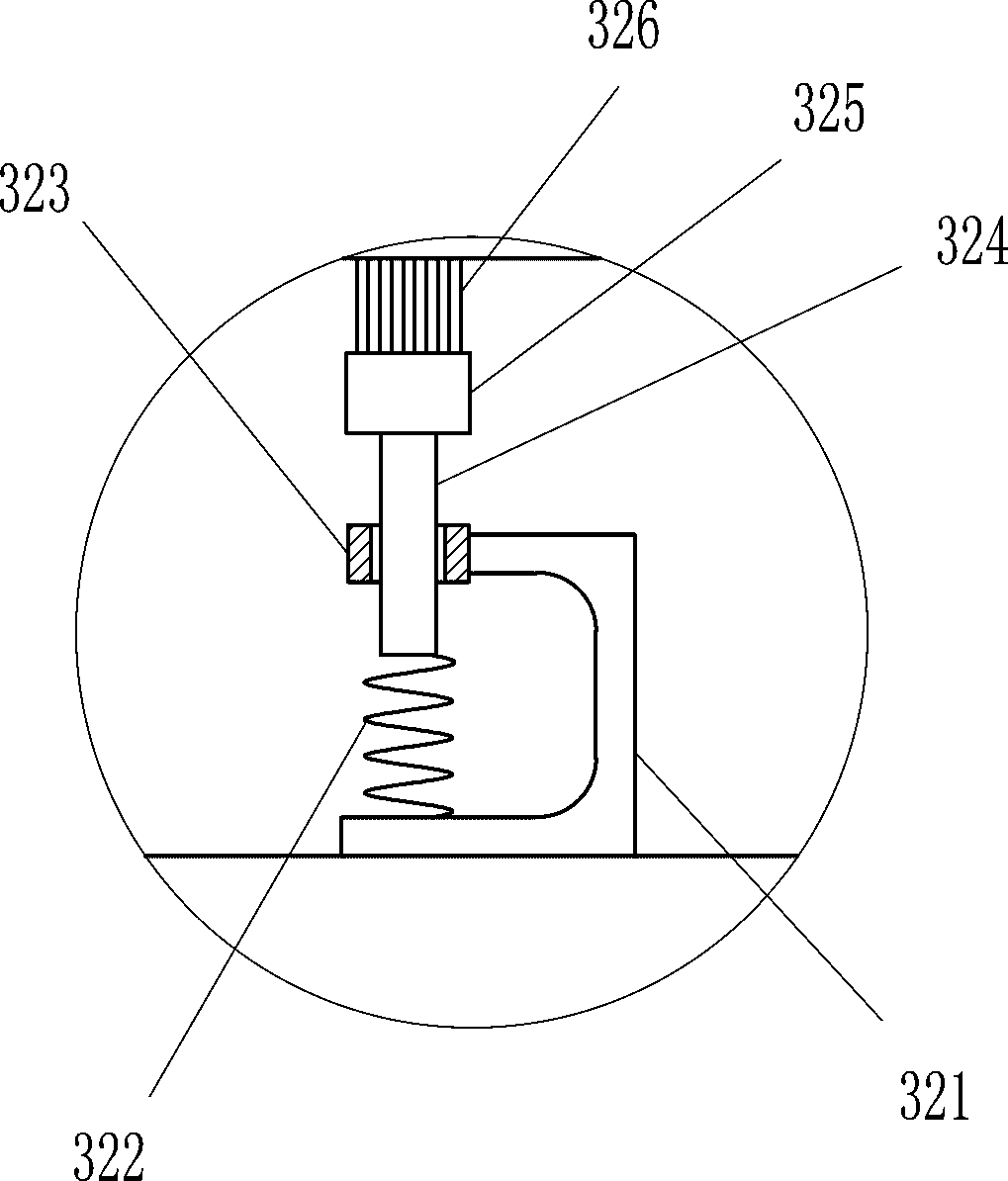

[0017] A kind of multi-chain bucket sand mining and washing equipment, such as Figure 1-3As shown, it includes a hull 1, a workbench 2, a first swing seat 3, a swing plate 4, a three-section oil cylinder 5, a chain plate 6, a loading hopper 7, a first roller 8, a second roller 9, a mounting plate 10, Servo motor 11, second swing seat 12, slide rail 13, slide block 14, rack 16, fixed plate 17, gear 18, rocking handle 19, blanking plate 20, clamping device 21, third fixed rod 22, the first Four fixed rods 23, sieve plate 24, the third idler 25, the fourth idler 26, transmission motor 27, the first pulley 28, the second pulley 29, belt 30 and transmission mesh belt 31, the top of the hull 1 is set There is a workbench 2, the upper left part of the workbench 2 is fixedly connected with a first swing seat 3, and the upper left part of the workbench 2 is fixedly connected with a swing plate 4, and the swing plate 4 is located on the left side of the first swing seat 3. The front s...

Embodiment 2

[0019] A kind of multi-chain bucket sand mining and washing equipment, such as Figure 1-3 As shown, it includes a hull 1, a workbench 2, a first swing seat 3, a swing plate 4, a three-section oil cylinder 5, a chain plate 6, a loading hopper 7, a first roller 8, a second roller 9, a mounting plate 10, Servo motor 11, second swing seat 12, slide rail 13, slide block 14, rack 16, fixed plate 17, gear 18, rocking handle 19, blanking plate 20, clamping device 21, third fixed rod 22, the first Four fixed rods 23, sieve plate 24, the third idler 25, the fourth idler 26, transmission motor 27, the first pulley 28, the second pulley 29, belt 30 and transmission mesh belt 31, the top of the hull 1 is set There is a workbench 2, the upper left part of the workbench 2 is fixedly connected with a first swing seat 3, and the upper left part of the workbench 2 is fixedly connected with a swing plate 4, and the swing plate 4 is located on the left side of the first swing seat 3. The front ...

Embodiment 3

[0022] A kind of multi-chain bucket sand mining and washing equipment, such as Figure 1-3 As shown, it includes a hull 1, a workbench 2, a first swing seat 3, a swing plate 4, a three-section oil cylinder 5, a chain plate 6, a loading hopper 7, a first roller 8, a second roller 9, a mounting plate 10, Servo motor 11, second swing seat 12, slide rail 13, slide block 14, rack 16, fixed plate 17, gear 18, rocking handle 19, blanking plate 20, clamping device 21, third fixed rod 22, the first Four fixed rods 23, sieve plate 24, the third idler 25, the fourth idler 26, transmission motor 27, the first pulley 28, the second pulley 29, belt 30 and transmission mesh belt 31, the top of the hull 1 is set There is a workbench 2, the upper left part of the workbench 2 is fixedly connected with a first swing seat 3, and the upper left part of the workbench 2 is fixedly connected with a swing plate 4, and the swing plate 4 is located on the left side of the first swing seat 3. The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com