Manual hole digging pile construction process for quicksand geologic condition

A technology of artificial digging piles and construction technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as affecting the construction progress, unable to continue excavation, etc., to increase the lateral compressive capacity, convenient transportation, The effect of easy hoisting and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

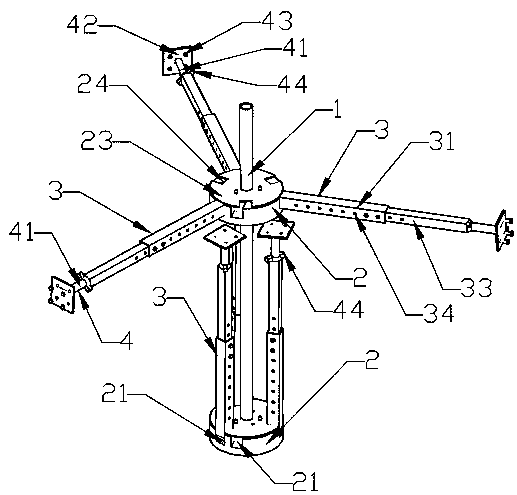

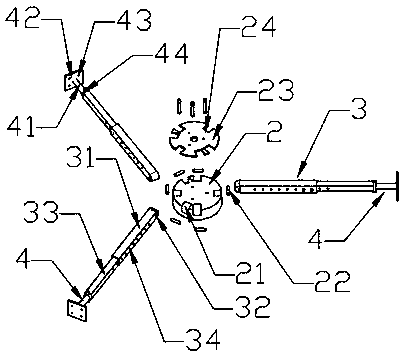

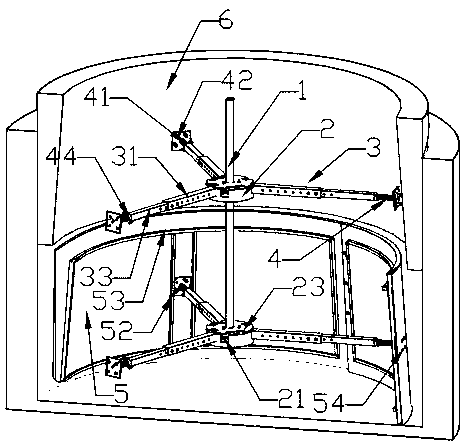

Image

Examples

Embodiment

[0025] The construction technology of the artificial excavated piles used in quicksand geology provided by this embodiment includes the following steps: Step 1, setting out and positioning, positioning and setting out the artificially excavated piles, and determining the center of the piles at the excavation site according to the design requirements point, take the center point of the pile as the center of the circle, draw a circle with the radius of the pile plus the thickness of the retaining wall as the radius, and determine the excavation sideline of the artificially excavated pile; step 2, excavate the first pile hole and pour the first retaining wall, excavate the second The first section of the pile hole earthwork is supported with a retaining wall formwork. After the excavation of the earthwork is completed, the retaining wall concrete is poured, and the retaining wall formwork of the first section is removed after the retaining wall is formed; step 3, the formwork suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com