Shaft coal uncovering method via radial technology

A technology of radial wells and vertical wells, which is applied in liquid/gas jet drilling, earthwork drilling, wellbore/well components, etc. It can solve the problems of tight construction period and long time for uncovering coal, so as to reduce engineering quantity and improve drainage Speed, the effect of reducing the risk of outstanding hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

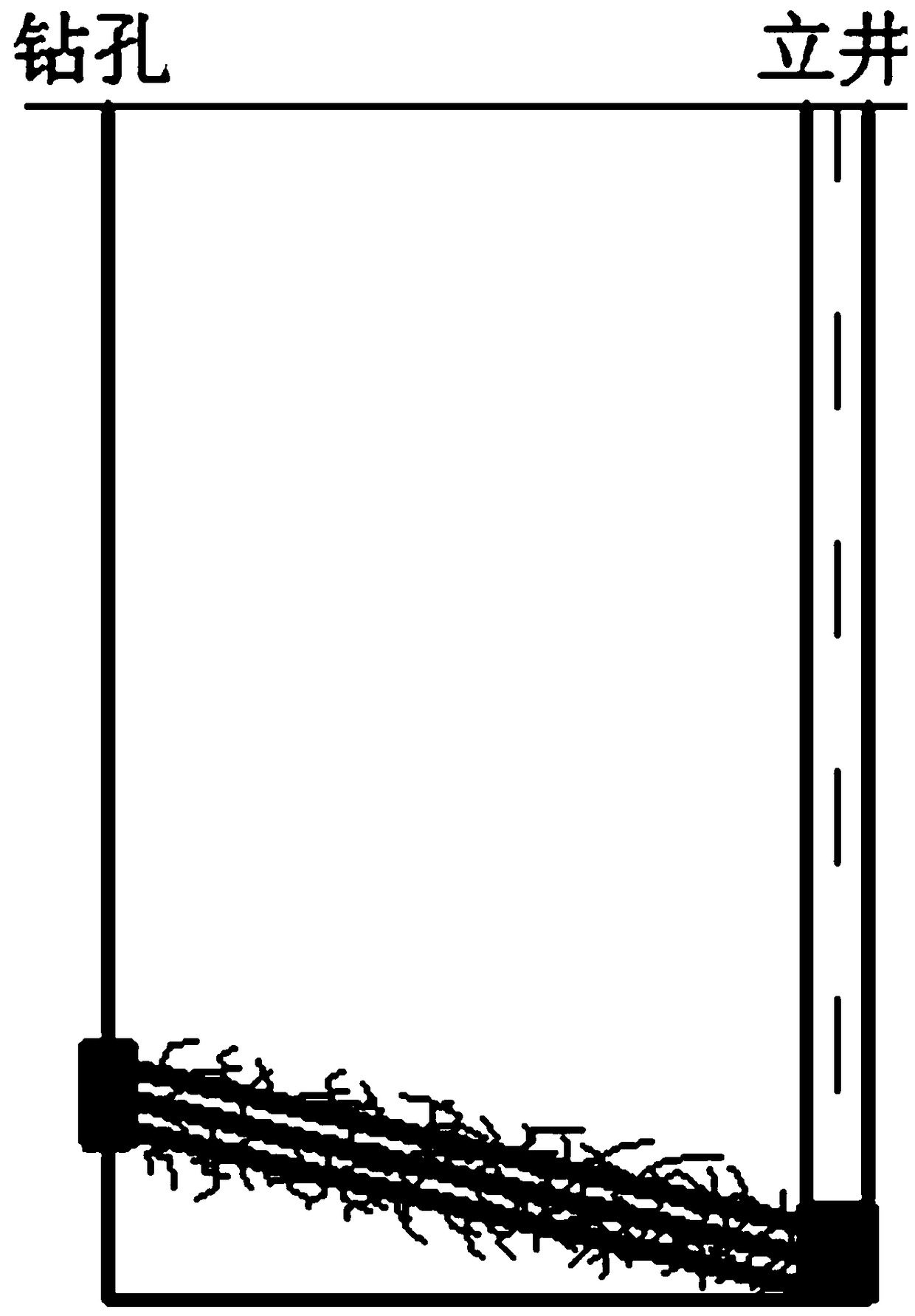

[0019] Radial well technology was first used in the petroleum industry, providing an economical and fast method for the exploitation of low-permeability and ultra-low-permeability oil and gas fields. Introducing radial well technology into the transformation of coalbed methane wells can achieve multiple purposes such as removing pollution near the well end, relieving stress concentration near the wellbore, communicating the original fractures of the coal seam and guiding fracturing, and then achieving the effect of single-well stimulation of coalbed methane wells.

[0020] The invention belongs to the use of coalbed methane wells around the vertical shaft to construct radial branches to the vertical shaft through ground drilling, and utilizes the guiding effect of the radial well to expand the influence range of fracturing cracks. In the rapid coal mining of vertical shafts in coal mines, the engineering quantity of underground drilling construction is reduced, which is extremel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com