Air inlet valve for air compressor

An intake valve and air compressor technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of difficult installation and adjustment, many fault points, and many seals, and achieves anti-vibration and good dispersion. The effect of force, easy installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

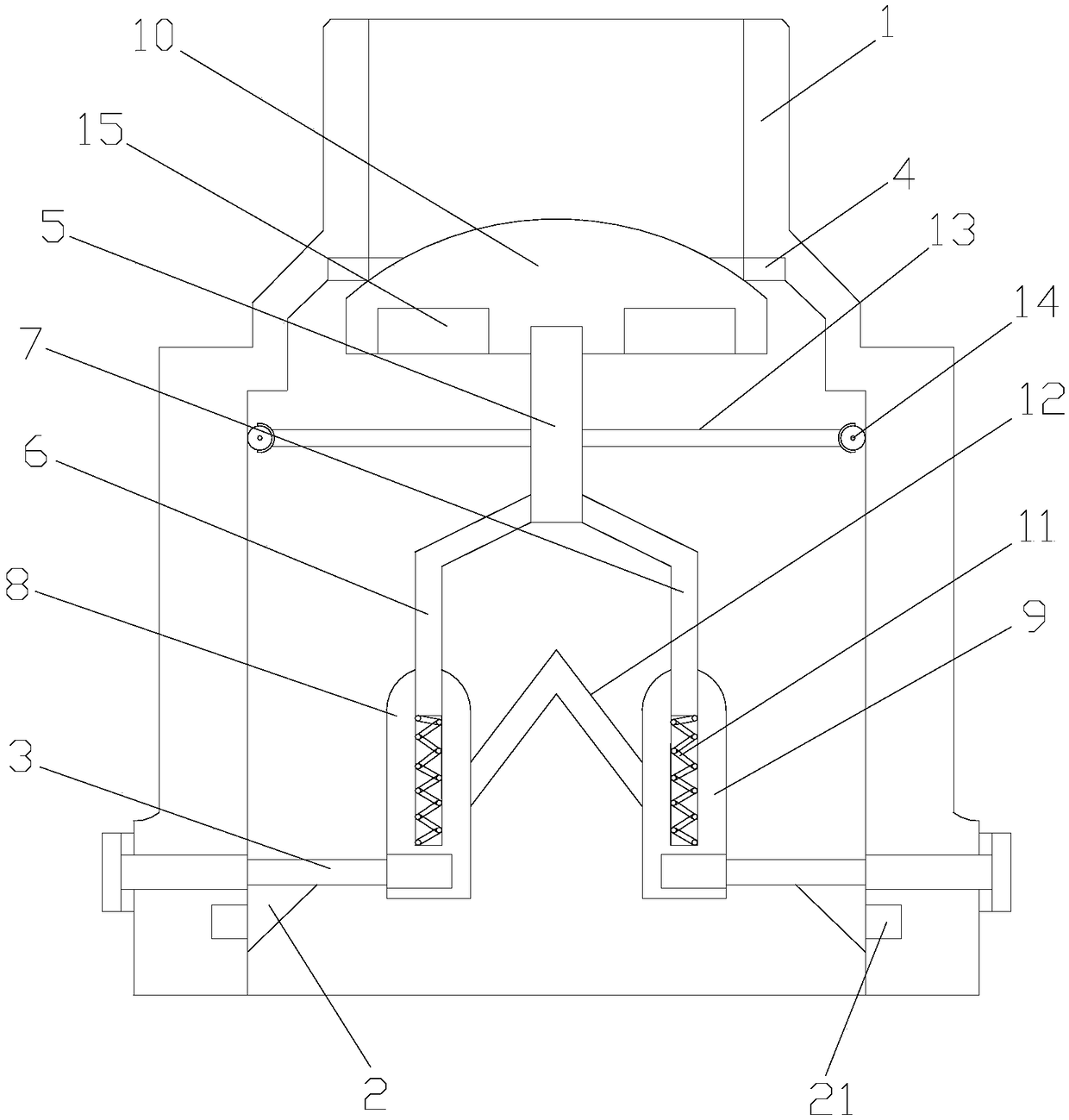

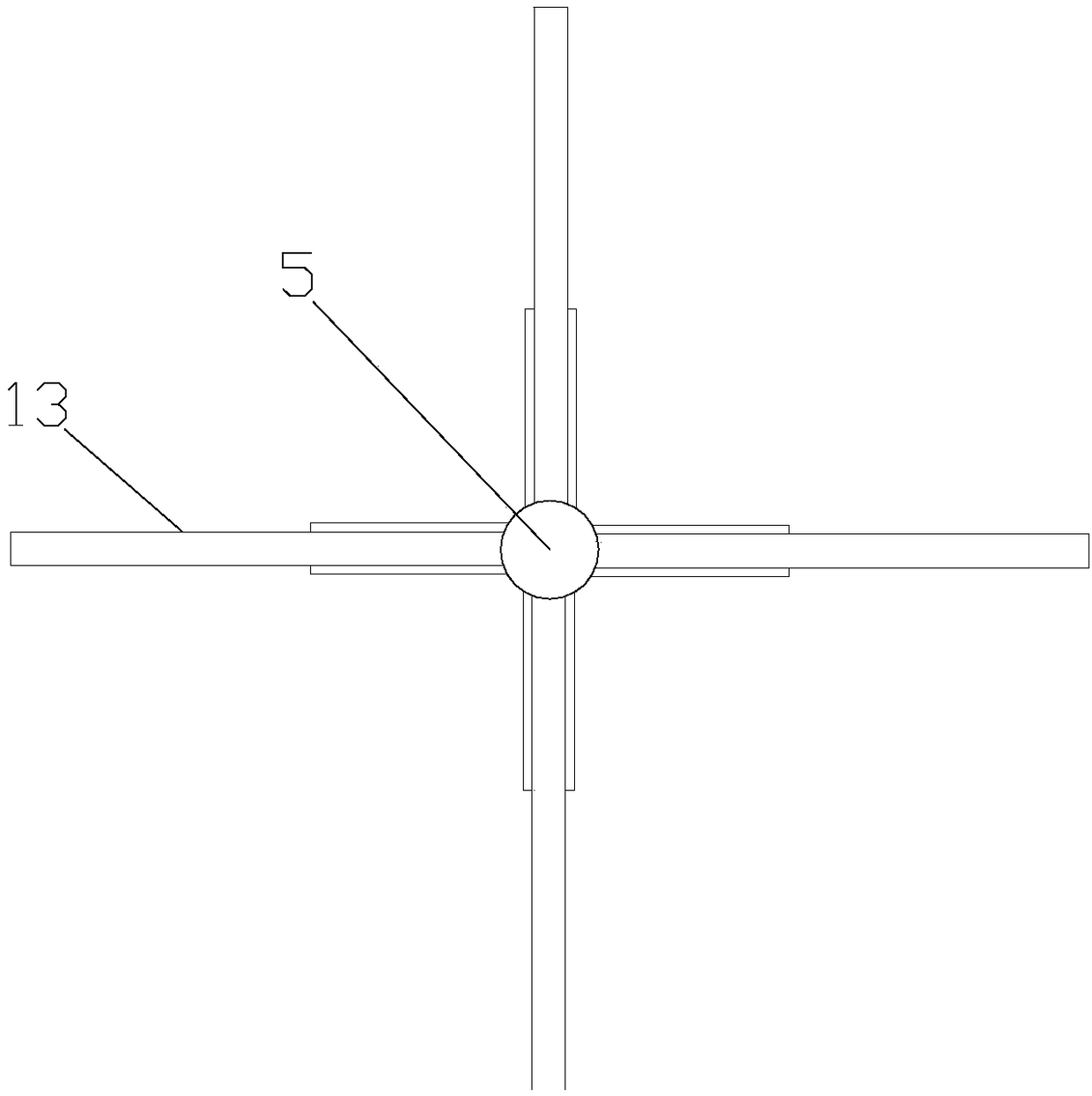

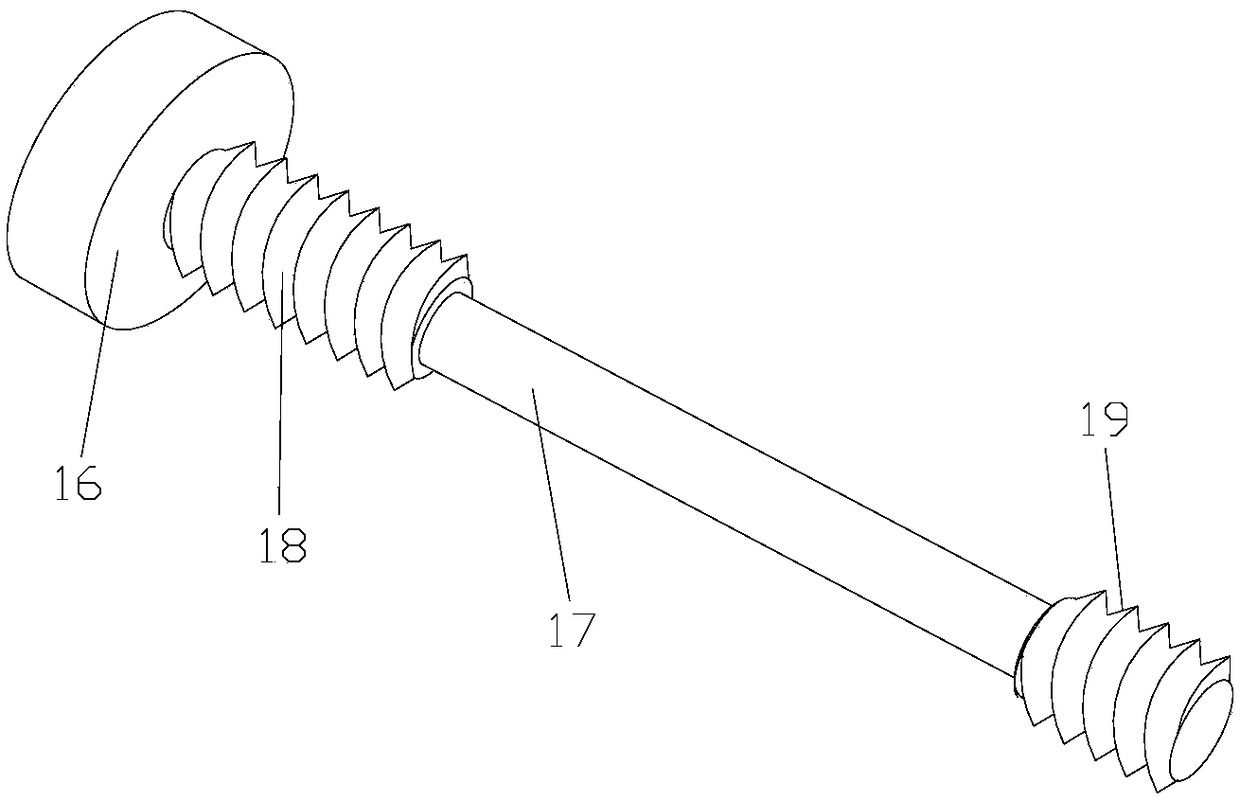

[0024] Such as Figure 1-3 As shown, an air intake valve for an air compressor includes an integrally formed valve casing 1, a valve core mechanism and a connecting body 3. A sealing rubber ring 4 is arranged inside the valve casing 1, and the top of the sealing rubber ring 4 Both the surface and the outer ring surface are bonded to the valve casing 1, and the valve core mechanism includes the valve stem 5, the first connecting rod 6, the second connecting rod 7, the first inserting sleeve 8, the second inserting sleeve 9 and rubber The ceramic valve core 10 matched with the sealing ring 4, the valve stem 5 is threadedly connected with the ceramic valve core 10, the first connecting rod 6 and the second connecting rod 7 are integrally arranged with the valve stem 5, and the first A connecting rod 6 and a second connecting rod 7 are all arranged in an obtuse angle, and a return spring 11 is arranged in the first inserting sleeve 8 and the second inserting sleeve 9, and the firs...

Embodiment 2

[0027] Such as Figure 1-3As shown, an air intake valve for an air compressor includes an integrally formed valve casing 1, a valve core mechanism and a connecting body 3. A sealing rubber ring 4 is arranged inside the valve casing 1, and the top of the sealing rubber ring 4 Both the surface and the outer ring surface are bonded to the valve casing 1, and the valve core mechanism includes the valve stem 5, the first connecting rod 6, the second connecting rod 7, the first inserting sleeve 8, the second inserting sleeve 9 and rubber The ceramic valve core 10 matched with the sealing ring 4, the valve stem 5 is threadedly connected with the ceramic valve core 10, the first connecting rod 6 and the second connecting rod 7 are integrally arranged with the valve stem 5, and the first A connecting rod 6 and a second connecting rod 7 are all arranged in an obtuse angle, and a return spring 11 is arranged in the first inserting sleeve 8 and the second inserting sleeve 9, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com