Micro-slip control system for wet double clutch automatic transmission

A wet dual clutch, automatic transmission technology, applied in transmission control, transmission parts, gear lubrication/cooling, etc., can solve the problem of excessive target slip and actual slip, clutch stuck, clutch ablation and other problems, to achieve the effect of easy implementation, convenient data collection, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

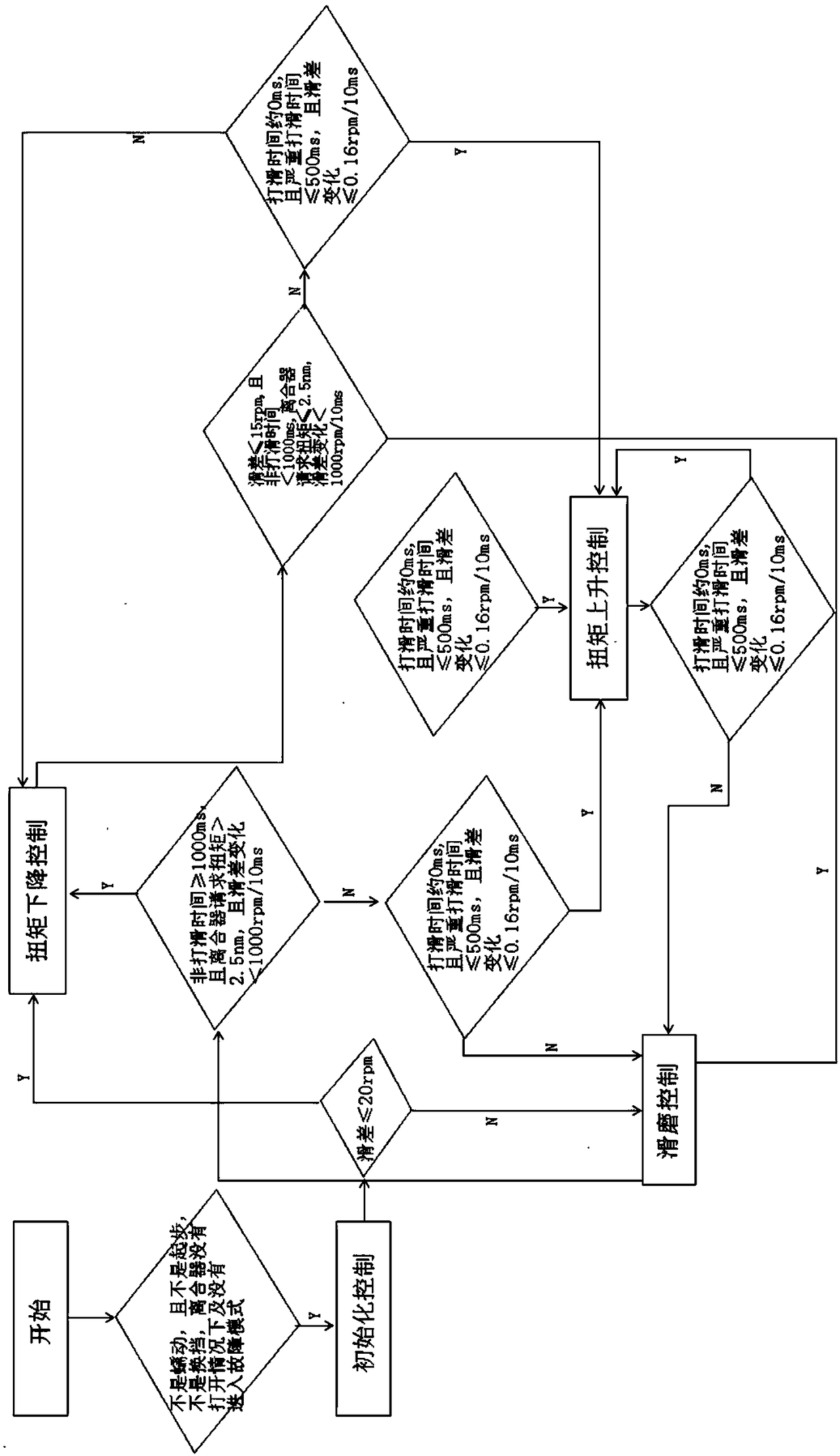

[0048] A micro-slip control method for a wet dual-clutch automatic transmission, such as figure 1 As shown, including initialization control, torque down control, torque up control and micro-slip grinding control.

[0049] Before the gearbox is controlled, it is first judged whether the gearbox meets the micro-slip control conditions. The micro-slip control conditions include that the gearbox is not creeping, it is not starting, it is not shifting, the clutch is not Open and not in failure mode.

[0050] After judging, if it matches, then proceed to the initialization control stage.

[0051] Under the initial control condition, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com