Dehumidification and humidification rotor

A rotor and air hole technology, applied in the field of dehumidification and humidification rotors, can solve the problems of time-consuming, low manufacturing efficiency, and reduced range, and achieve the effects of easy manufacturing, good efficiency, and increased range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in detail based on the illustrated embodiments.

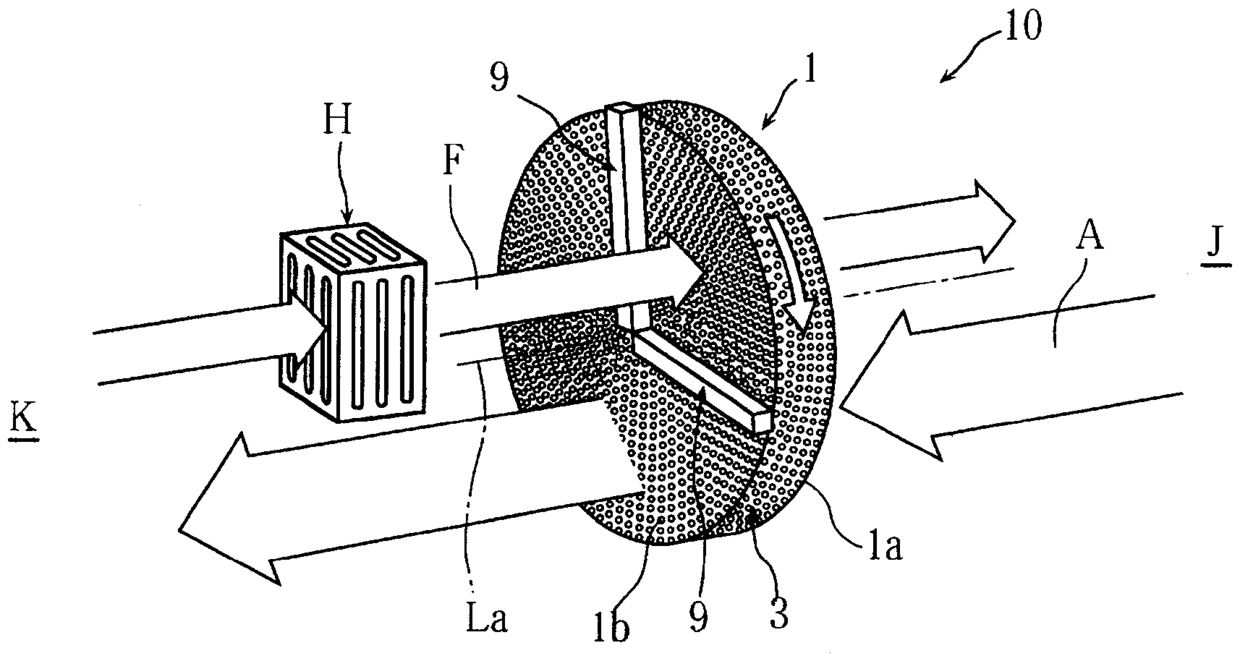

[0015] figure 1 Showing the first embodiment of the present invention, this dehumidification and humidification rotor is used in a desiccant air conditioner and is also called a desiccant rotor.

[0016] Such as figure 1 As shown, the desiccant-type air conditioner 10 is configured to rotate the dehumidification and humidification rotor 1 around the rotor axis La, suck in the process air A containing moisture (moisture) from the side J of the rotor axis, and pass the process air A A part of the dehumidifying and humidifying rotor 1 absorbs moisture, and the hot air F heated by a heat source H such as a heater passes through the remaining part of the dehumidifying and humidifying rotor 1 from the other side K of the rotor axis to discharge the adsorbed moisture to one side of the axis J Conveying hot air F containing moisture. The rotational speed of the dehumidifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com