Optimal scheduling method based on multi-plant steelmaking-continuous casting billet production process

A technology of optimal scheduling and fruit fly optimization algorithm, applied in the directions of comprehensive factory control, comprehensive factory control, program control, etc., can solve the problems of the impact of the total completion time of batch production of steel billets, so as to reduce production costs, avoid waste, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

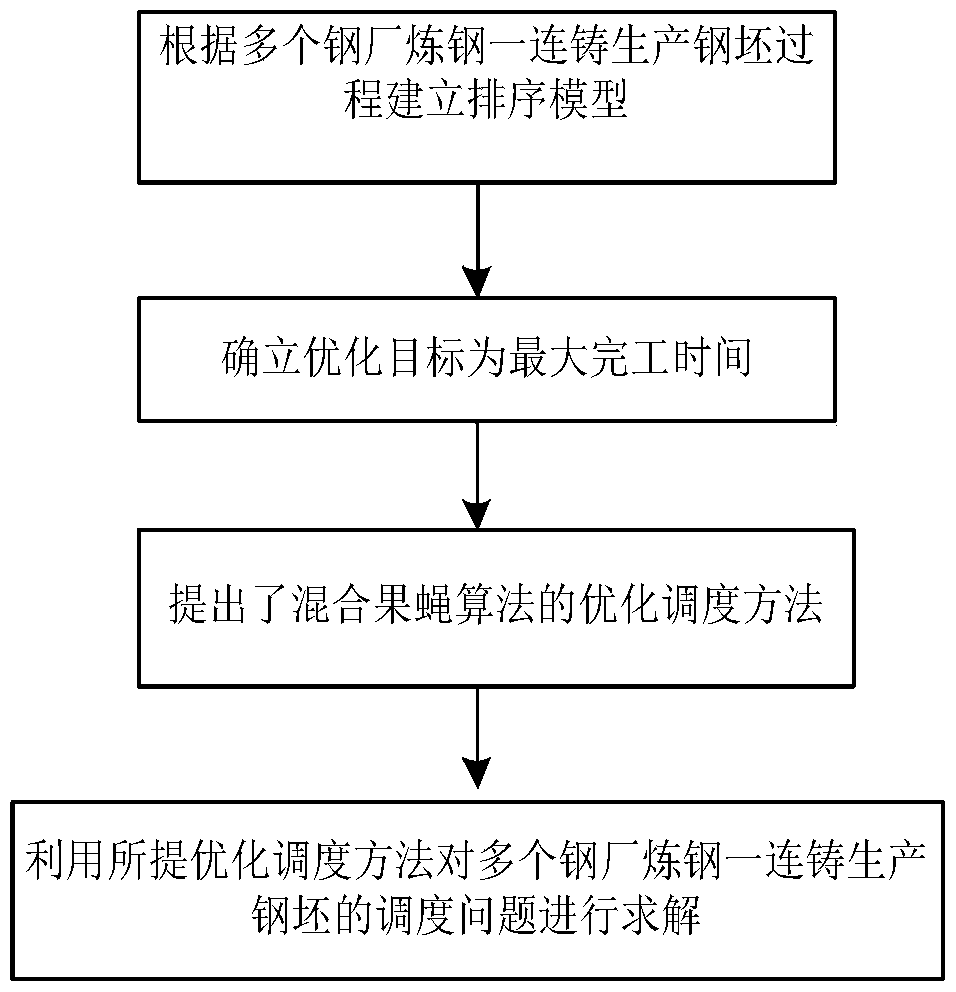

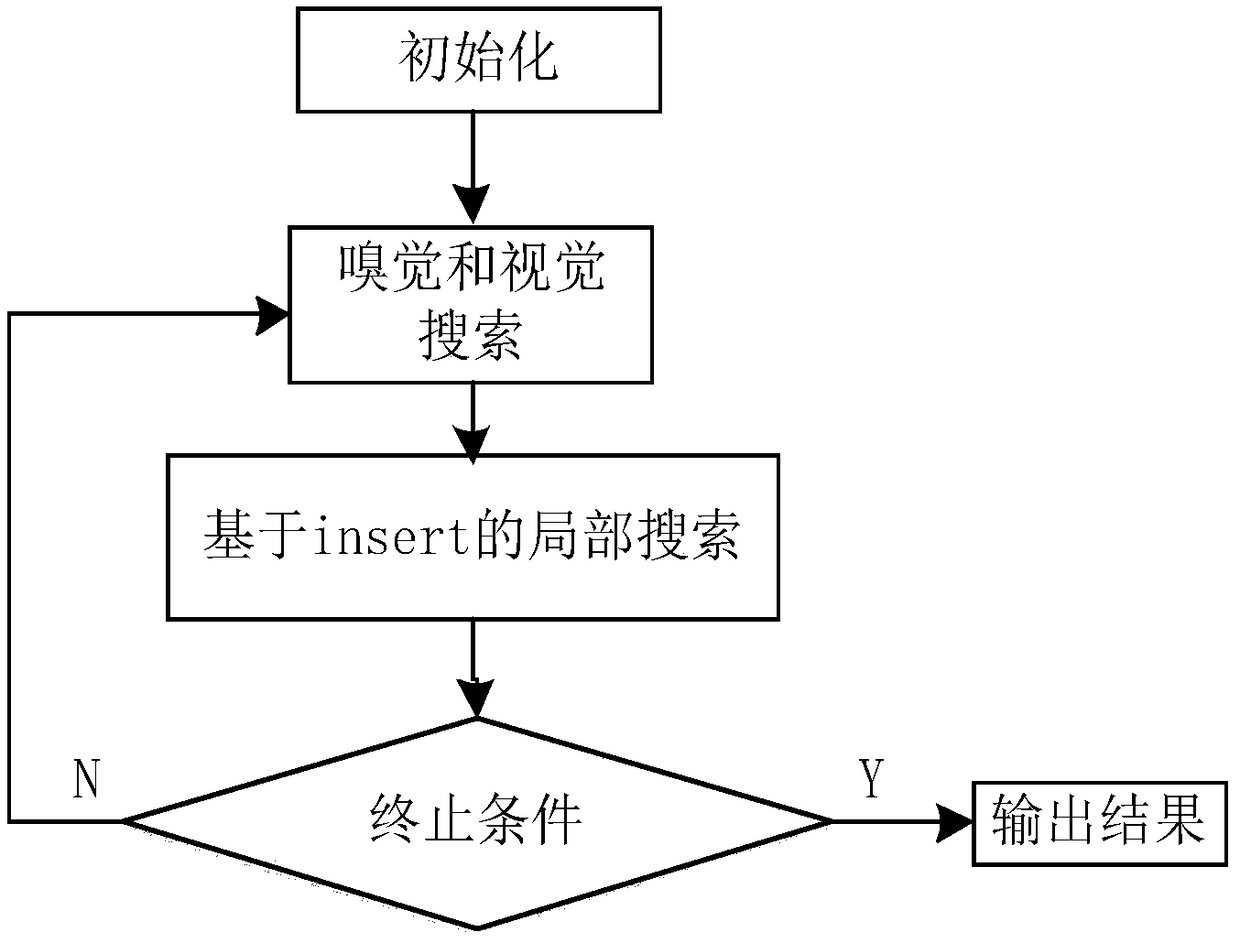

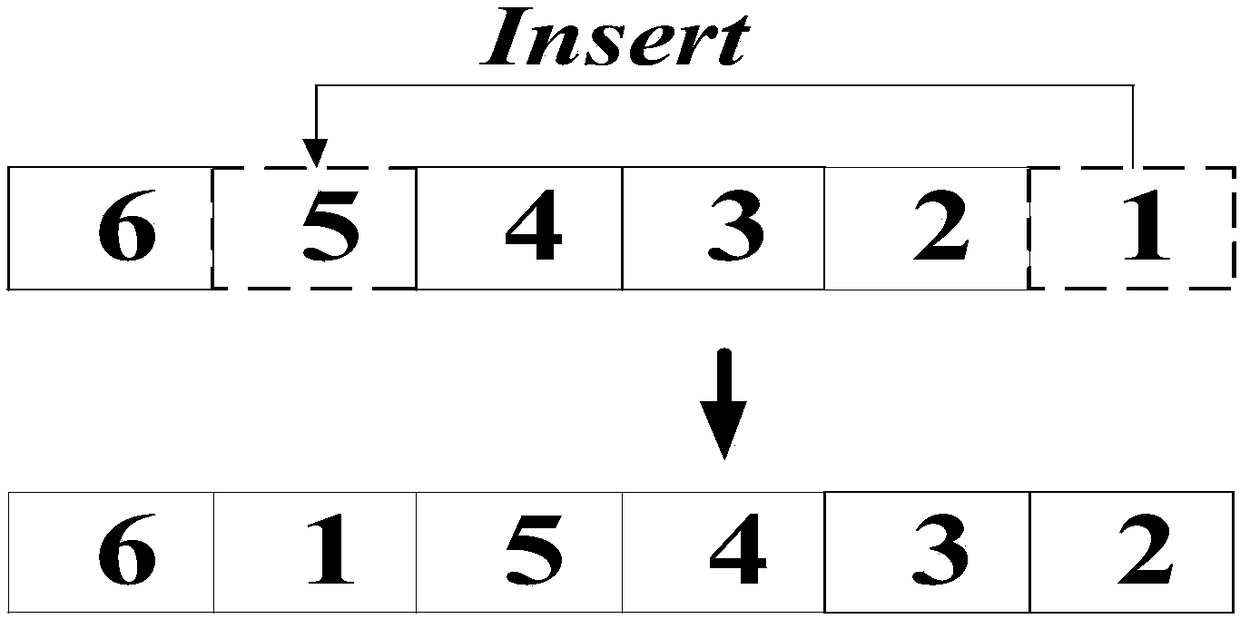

[0027] Embodiment 1: as Figure 1-3 As shown, an optimal scheduling method based on the multi-factory steelmaking-continuous casting billet production process, by determining the scheduling model and optimization objectives of the steelmaking-continuous casting billet production process in multiple steel plants for different billets, and using the mixed results The optimization scheduling method of the fly optimization algorithm optimizes the target; among them, the scheduling model is established according to the processing time of different steel billets on different steel mill machines, and the optimization goal is to minimize the maximum completion time C max (π)

[0028]

[0029]

[0030]

[0031] k=1,2,···F,i=1,2,···,n k ,j=1,2,...,m

[0032] In the formula, F means that there are F steelmaking factories, k means a specific factory, n means the total number of billets to be processed, and n k Indicates the total number of billets to be processed in factory k,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com