Optical coupling device

A technology for optical coupling devices and mounting components, which is applied in the direction of electromagnetic transceivers, electrical components, and electrical solid devices, and can solve problems affecting the characteristics of optical coupling devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

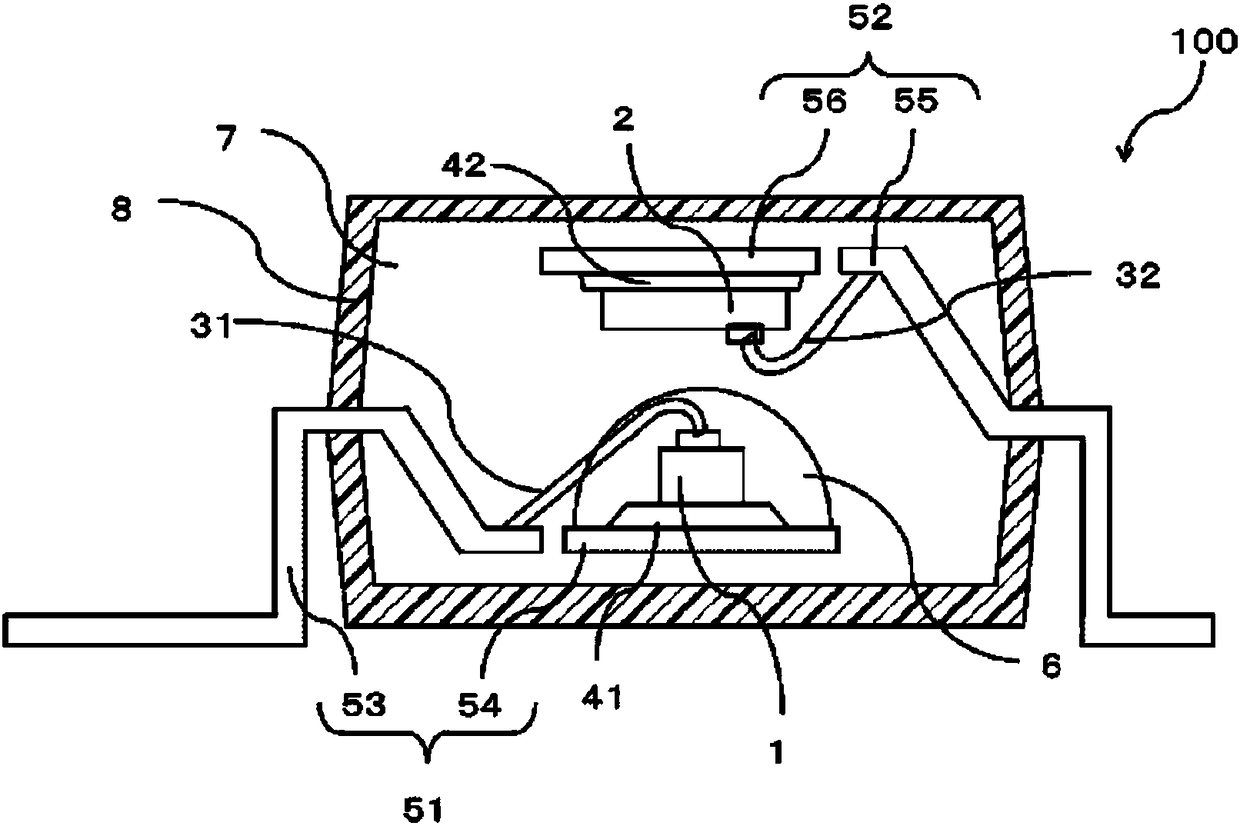

[0012] The embodiments will be described below with reference to the drawings. In the following description, the same reference numerals are assigned to the same members, and the description of the members that have been described is omitted as appropriate.

[0013] Such as figure 1 As shown in the figure, the optical coupling device 100 includes a light transmitter 1, a light receiver 2, a first wire 31, a second wire 32, a first mounting member 41, a second mounting member 42, a first lead frame 51, and a second lead The frame 52, the encapsulating resin 6, the inner resin 7 and the outer resin envelope 8.

[0014] The light emitter 1 is, for example, a light emitting diode (LED).

[0015] The first lead frame 51 and the second lead frame 52 are made of conductive members such as metal. In addition, the first lead frame 51 includes a first outer lead 53 and a first plane portion 54. The second lead frame 52 includes a second outer lead 55 and a second plane portion 56.

[0016] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com