A welded air tube secondary radar antenna box

A secondary radar and welding technology, which is applied to antennas, antenna components, antenna supports/installation devices, etc., can solve problems such as increasing installation difficulty, unfavorable batch production, and reducing installation accuracy, so as to reduce the welding area , Realize mass production and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Now illustrate structural features of the present invention in conjunction with accompanying drawing:

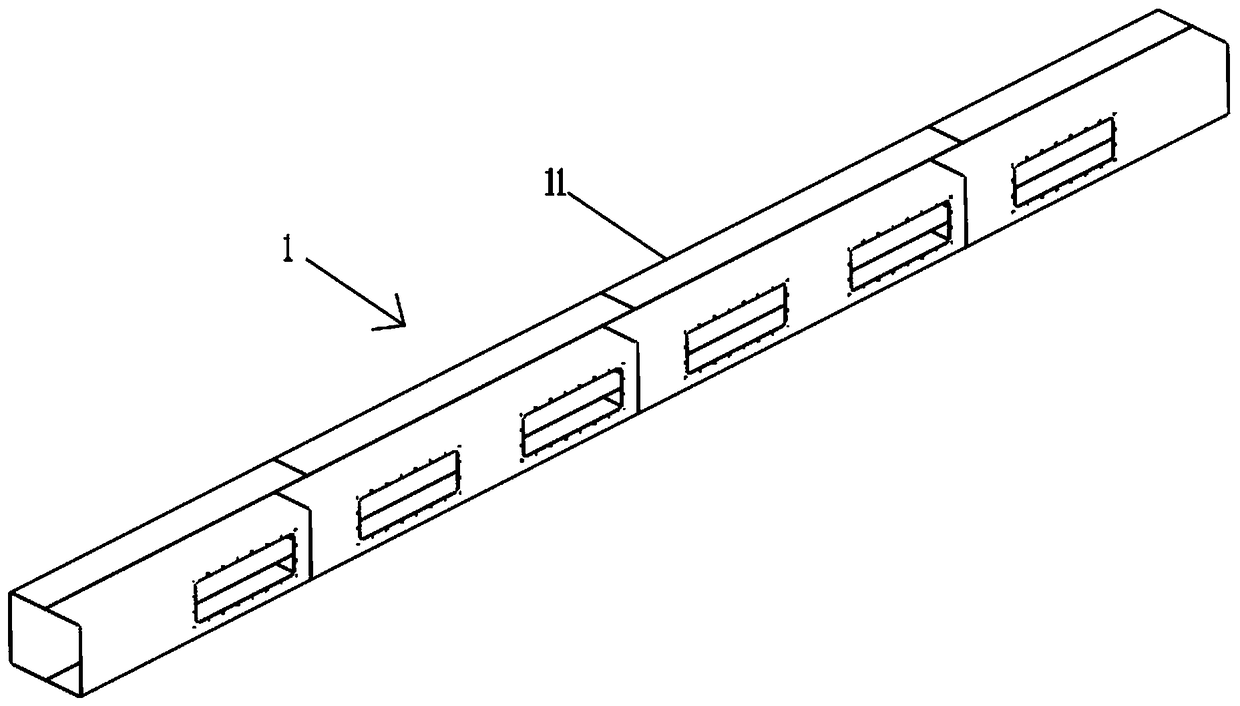

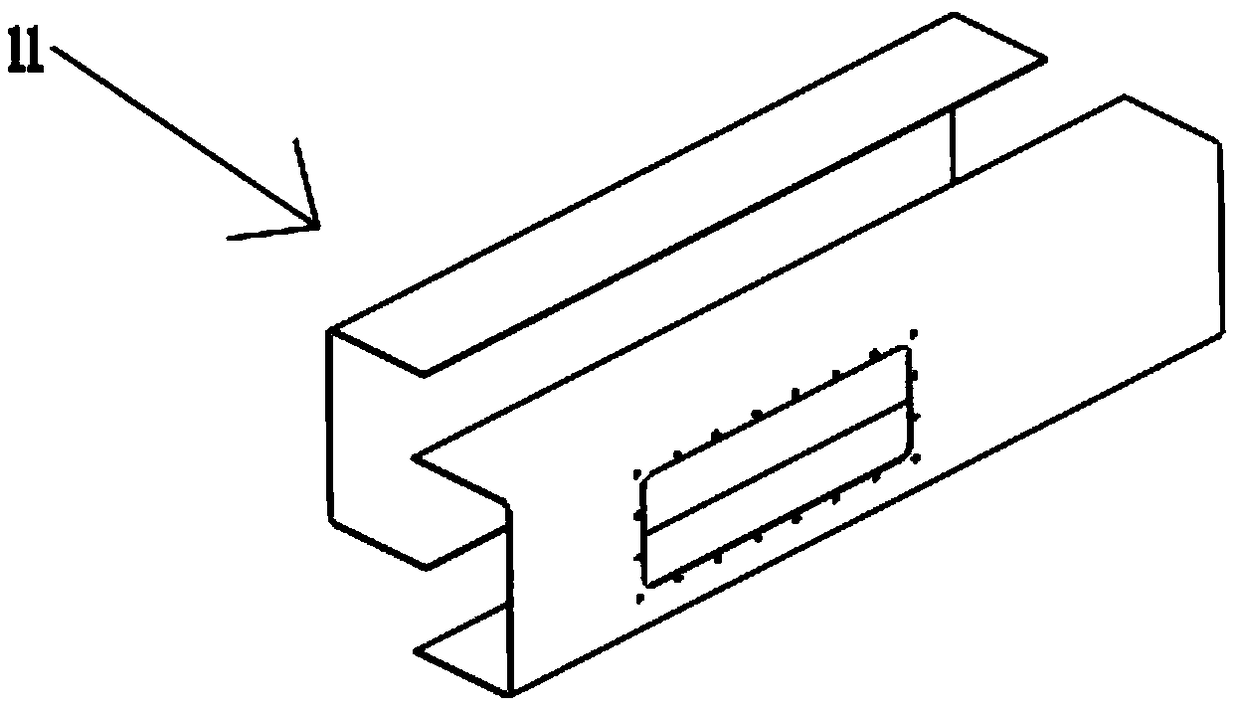

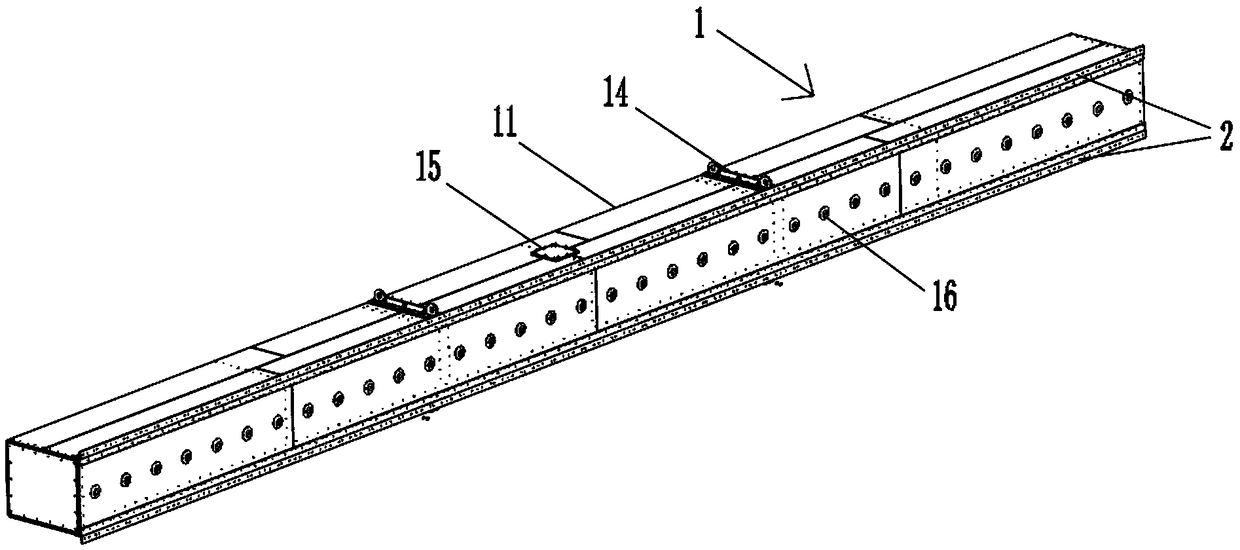

[0043] The antenna box 1 is assembled and welded sequentially by several segmented boxes 11 , and each segmented box 11 is formed by welding the open ends of two U-shaped box plates oppositely.

[0044] Such as figure 2 As shown, the welding of a single box is first performed, that is, the two aluminum alloy plates are first bent into a U shape, and then a maintenance window is opened on one of the boxes, and the first cover plate 12 is set at the position of the maintenance window, and then The U-shaped aluminum alloy plate is fixed on the working platform of the semi-automatic welding equipment, and the welding operation of the segmented box body 11 can be completed by inputting process parameters. After the welding of a single box is completed, the two-section box 11 is fixed on the welding platform, and the staggered ends of the two section boxes 11 are engaged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com