Automatic cold drink processing equipment

A processing equipment and cold drink technology, applied in the direction of frozen sweets, food science, application, etc., can solve the problems of impracticability and hidden hygiene hazards of cold drinks, and achieve the effects of ensuring hygiene, quick production, and reducing the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

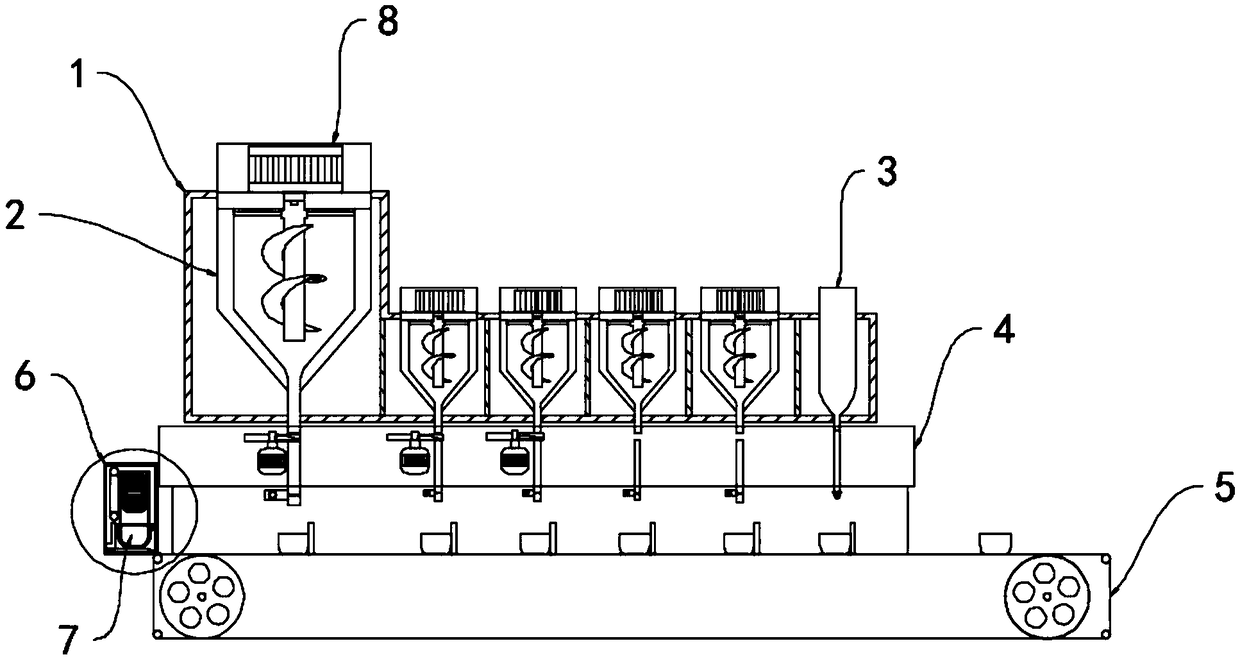

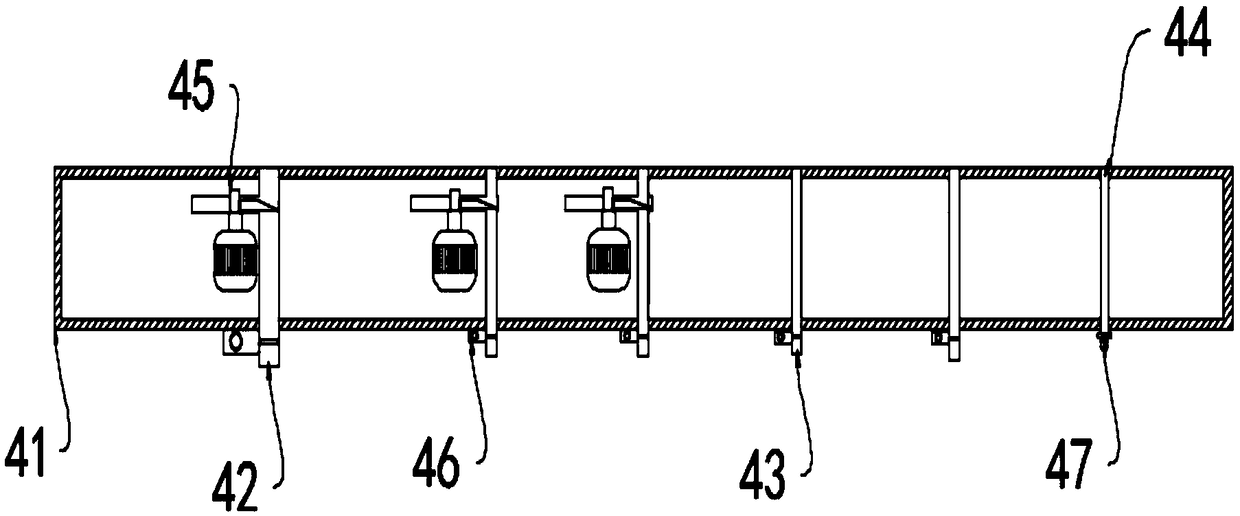

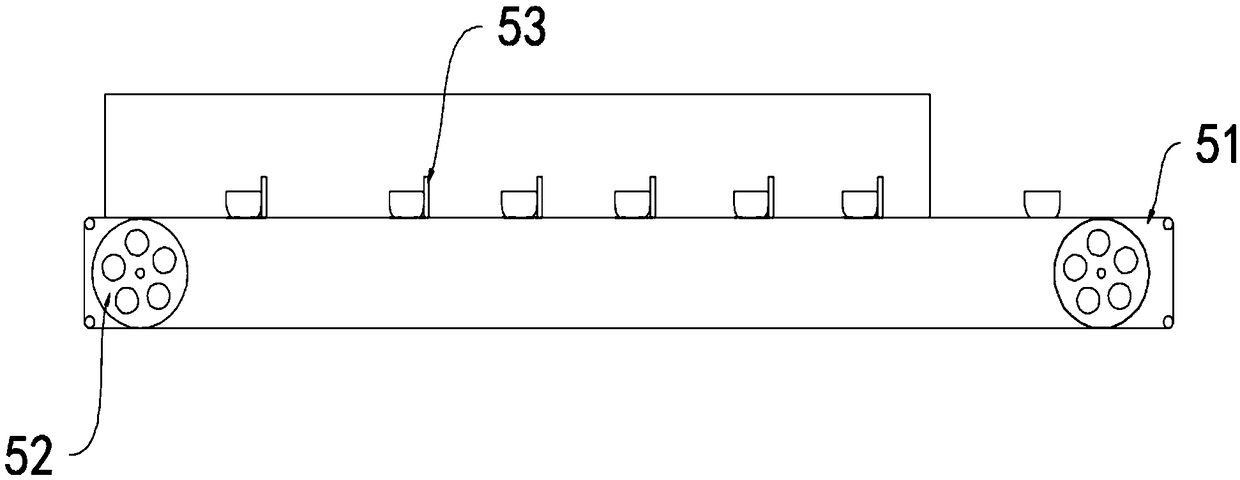

[0029] An automatic cold drink processing equipment provided by a preferred embodiment of the present invention includes a box body 1, a material storage tank 2, a sugar water tank 3, a forming conveying device 4, a cabinet-type conveying platform 5, a bowl storage box 6 and a conveying vehicle 7. The storage tank 2 and the sugar water tank 3 are placed inside the box body 1, the forming delivery device 4 is placed under the box body 1, the forming delivery device 4 is connected with the material storage tank 2 and the sugar water tank 3 respectively, and the cabinet The conveying table 5 is placed under the forming conveying device 4, the cabinet conveying table 5 is connected with the box body 1 and the forming conveying device 4 respectively, the bowl storage box 6 is connected with the forming conveying device 4, and the bowl storage box 6 On the top left of the cabinet-type transfer platform 5, the transfer cart 7 is placed inside the bowl storage box 6.

[0030] Describe...

Embodiment 2

[0036] The preferred embodiment of the present invention makes the following optimizations on the basis of Embodiment 1: the box body 1 is a refrigeration box, and the box body 1 also includes a partition, and the partition board is placed inside the box body 1, and the box body 1 The partition is placed between the storage tank 2 and the sugar water tank 3.

[0037] The working principle of this embodiment: the box body 1 of the prior art is used for installing the material storage tank 2 and the sugar water tank 3, and has a single function; this scheme utilizes the internal space of the box body 1 to be set as a refrigeration box, and a partition is set at the same time, The cooling area can be reduced and partitioned cooling can be performed at the same time. Due to the lower temperature, the storage time of the ingredients is prolonged while retaining the necessary taste; this solution has the characteristics of extending the storage time of the ingredients while retaining...

Embodiment 3

[0039] The preferred embodiment of the present invention has made the following optimizations on the basis of Embodiment 1: it also includes a push structure 8, which is placed above the storage tank 2, and the push structure 8 includes a tank body sealing cover 81, a miniature Motor 82, wedge-shaped connection port 83, push worm 84 and rotating support frame 85, described tank body sealing cover 81 is placed on the top of box body 1, and described tank body sealing cover 81 is threadedly connected with storage tank 2, and described miniature The motor 82 is placed inside the tank sealing cover 81, the micro motor 82 is connected with the push worm 84 through the wedge-shaped connection port 83, the push worm 84 adopts a bearing to be installed in the center of the rotating support frame 85, and the rotating support frame 85 is installed on The interior of storage tank 2.

[0040] The working principle of this embodiment: the prior art uses the fluidity of the ingredients and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com