Asphalt smoke treatment system

A flue gas treatment and treatment system technology, applied in the field of asphalt flue gas treatment, can solve the problems of unsatisfactory purification effect and high purification burden of treatment equipment, and achieve ideal and obvious purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

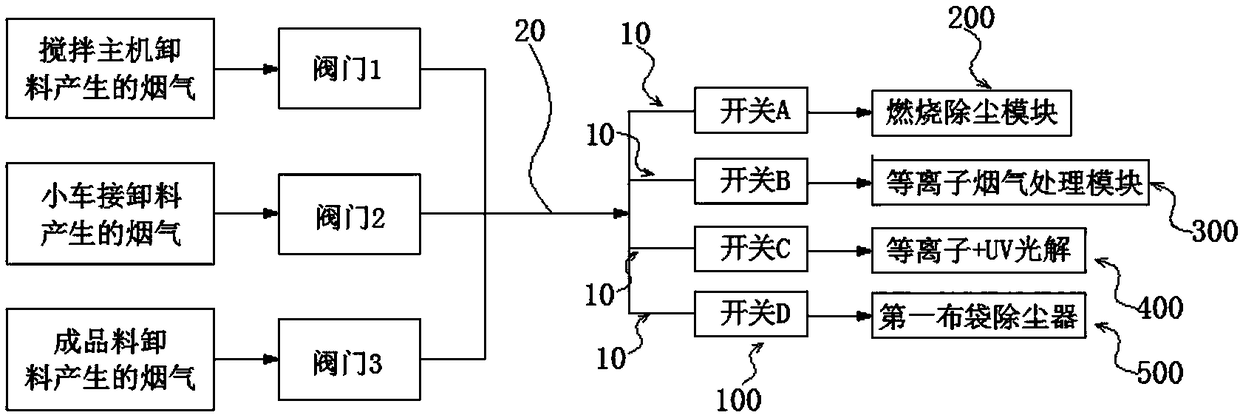

[0036] Such as Figure 1 to Figure 6 As shown, the first embodiment provides an asphalt flue gas treatment system, including: at least two flue gas treatment branches 10 arranged in parallel; each flue gas treatment branch 10 is provided with a switch 100 and a flue gas Processing modules; wherein, at least one flue gas treatment module in the flue gas treatment branch 10 is used to remove flue gas, and at least one flue gas treatment module in the flue gas treatment branch 10 is used to remove dust.

[0037] It should be noted that, in the above-mentioned "at least one flue gas treatment module in the flue gas treatment branch 10 is used to remove flue gas", the flue gas here includes dust-free flue gas and dust-laden flue gas.

[0038]In the bitumen flue gas treatment system of this embodiment, since there are multiple flue gas treatment branches 10, and each flue gas treatment branch 10 is arranged in parallel, each flue gas treatment branch 10 can be Work independently wi...

Embodiment 2

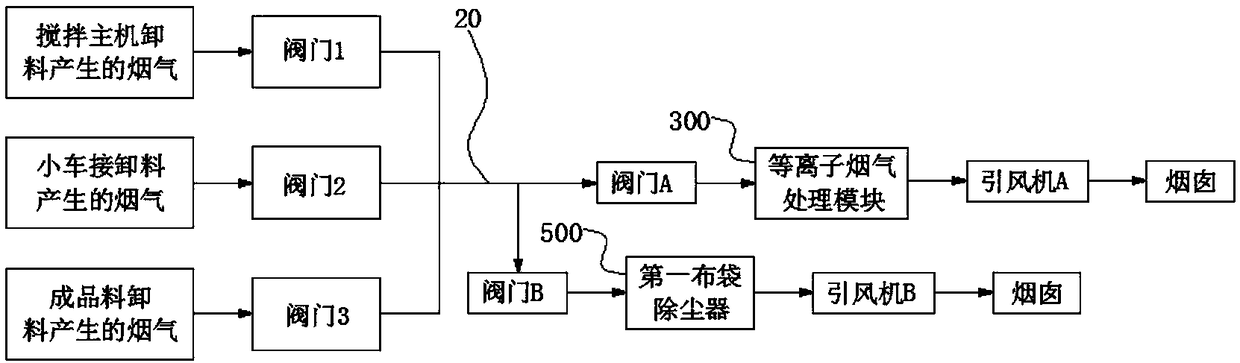

[0070] The second embodiment also provides an asphalt flue gas treatment system, wherein the asphalt flue gas treatment system includes components with the same names and working principles as those in the first embodiment, and its structure is the same as that of the asphalt gas in the first embodiment. The flue gas treatment systems are basically the same, with the differences described below.

[0071] In this embodiment, along the flow direction of the flue gas, the inlet end of the flue gas treatment branch 10 arranged in parallel is connected to the flue gas output end of the asphalt supply equipment, and the outlet end of the flue gas treatment branch 10 arranged in parallel is connected to the flue.

[0072] Wherein, a main induced fan is provided on the pipeline between the outlet end of the flue gas treatment branch 10 and the flue, and the main induced fan is connected to the chimney through the pipeline. During work, the switch 100 on the working branch is opened, a...

Embodiment 3

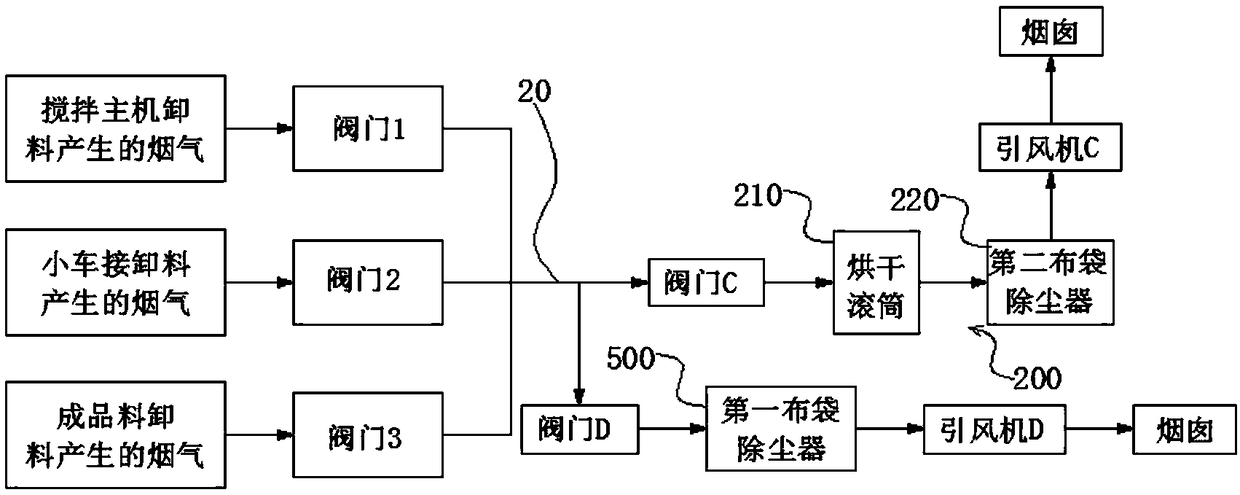

[0074] The third embodiment also provides an asphalt fume treatment system, wherein the asphalt fume treatment system includes parts and components with the same names and working principles as those in the first embodiment, and its structure is the same as that of the asphalt in the first embodiment The flue gas treatment systems are basically the same, with the differences described below.

[0075] For the branch circuit whose flue gas treatment module is set as the plasma flue gas treatment module 300, the flue gas can be sent into the specially designed plasma flue gas treatment module 300, or sent to the existing plasma flue gas treatment of the factory or construction site. Module 300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com