Building waste crushing and recycling device

A technology for recycling device and construction waste, applied in the field of construction waste crushing and recycling device, can solve the problems of easily polluting the environment, large waste volume, increasing construction difficulty, etc., and achieves a high degree of integration, simple and efficient process, and less dust emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

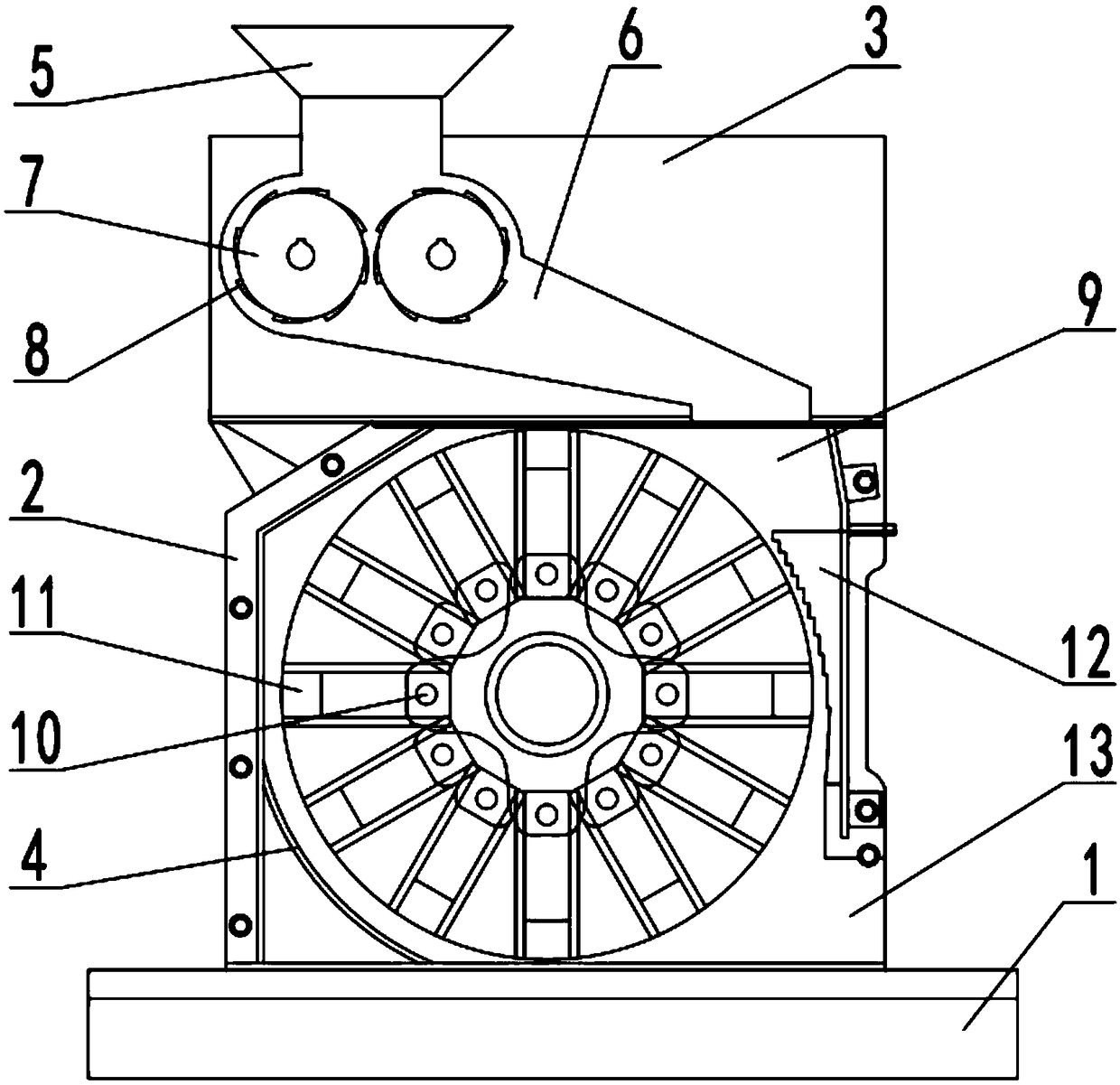

[0020] see Figure 1~3 , in an embodiment of the present invention, a construction waste crushing and recycling device includes a base 1, a fixed outer frame 2, a crushing shell 3 and a crushing shell 4, the base 1 is fixedly mounted with a fixed outer frame 2, and the fixed outer frame 2 The crushing shell 4 is installed, and the crushing shell 3 is fixedly installed on the fixed outer frame 2. The crushing shell 3 is provided with a crushing chamber 6, and a pair of crushing rollers 7 with opposite rotation directions are installed in the crushing chamber 6. The surface of the crushing roller 7 is Teeth 8 are fixed, and a lower hopper 5 is installed on the top of the crushing shell 3. When the construction waste put into the lower hopper 5 enters between the crushing rollers 7, it can be crushed by the relatively rotating crushing rollers 7. The crushing chamber The bottom of the crushing chamber 6 is connected to the crushing shell 4 through the discharge opening 9. In orde...

Embodiment 2

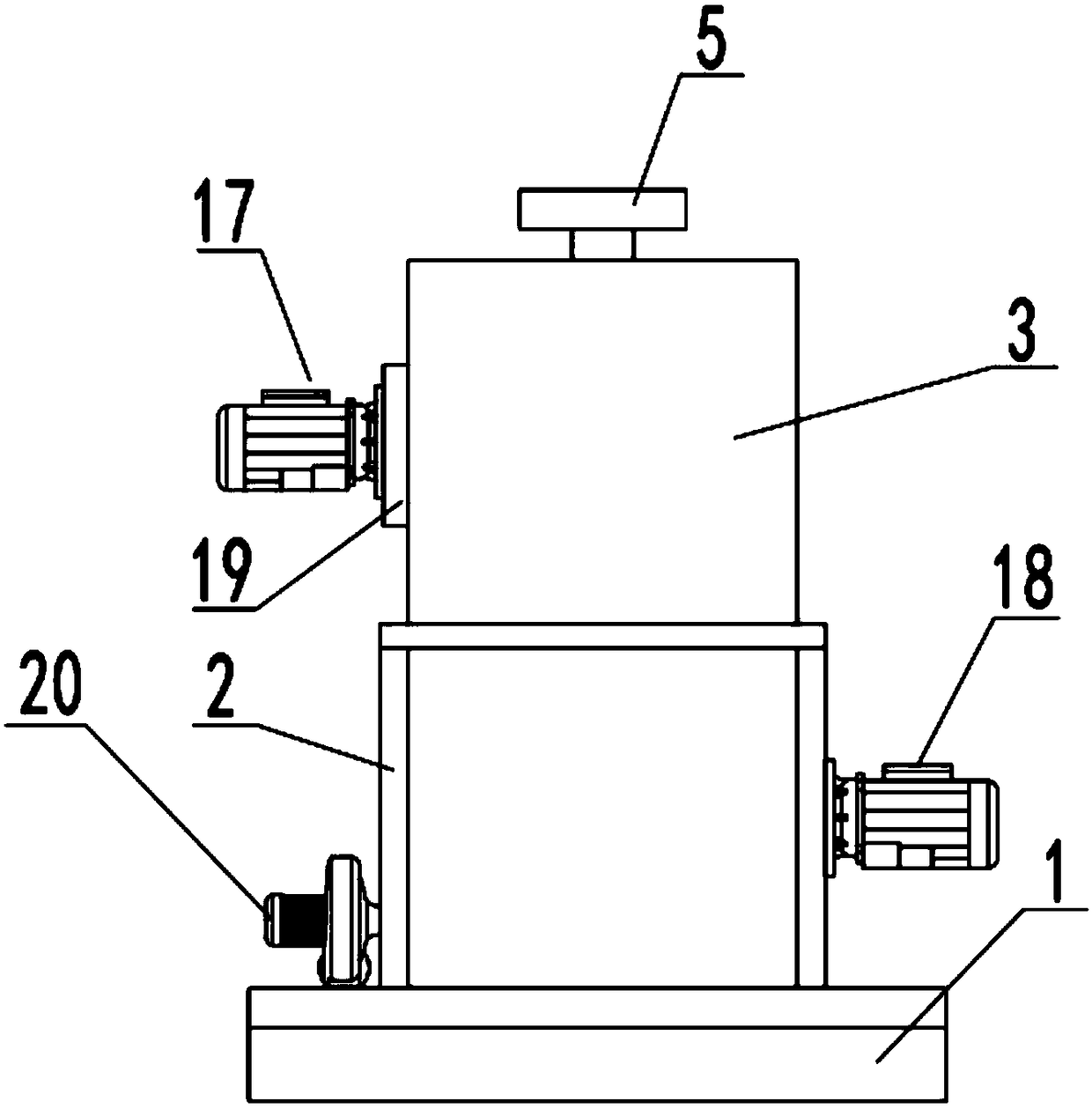

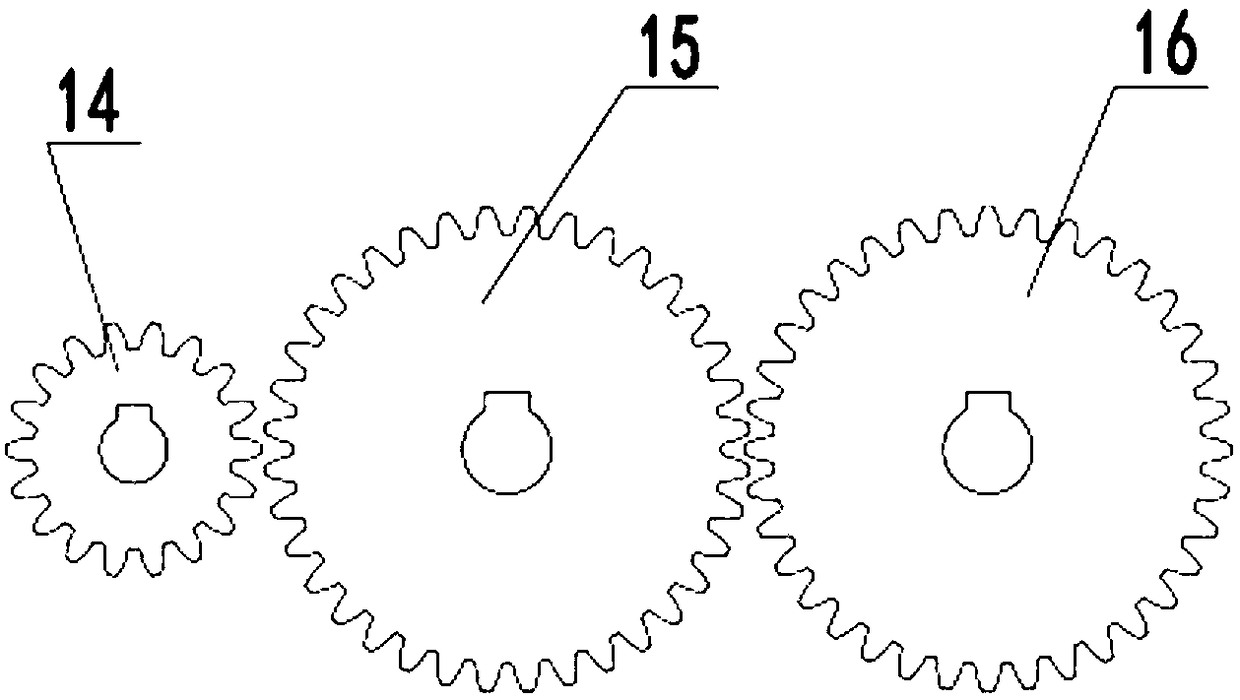

[0024] see Figure 1~3 , this embodiment is mainly to further illustrate the driving structure of the crushing roller 7 and the crushing blade 11. Specifically, the crushing shell 3 is equipped with a gear box 19, and the gear box 19 is equipped with a crushing motor 17, and the crushing motor 17 The output end stretches into the gear box 19 and is fixedly connected with the driving gear 14. The gear box 19 is also provided with a driven gear one 15 and a driven gear two 16 which mesh with each other. The driven gear one 15 and the driven gear two 16 are installed on the axle ends of two crushing rollers 7 respectively, and driving gear 14 meshes with driven gear one 15 or driven gear two 16 for realizing the relative rotation of two crushing rollers 7 . A crushing motor 18 is fixed outside the crushing shell 4, and the output end of the crushing motor 18 is connected with the drum for driving the drum to rotate at a high speed. Both the crushing motor 17 and the crushing mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com