Reutilization device for building waste

A construction waste and box technology, applied in grain processing and other directions, can solve the problems of incomplete crushing, short service life, and reduced screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

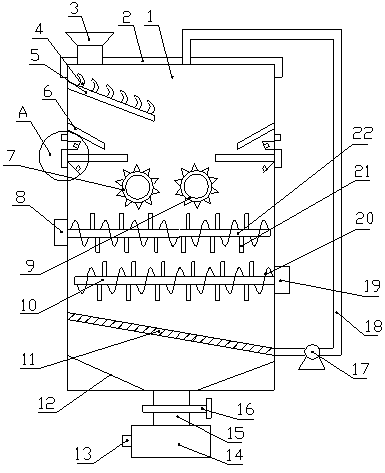

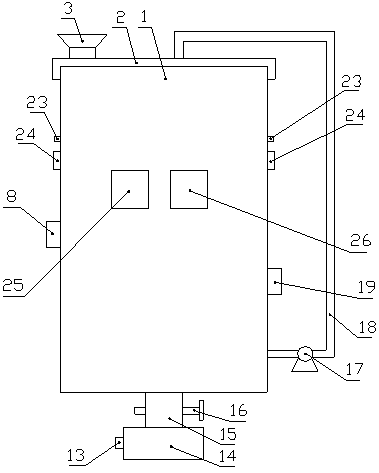

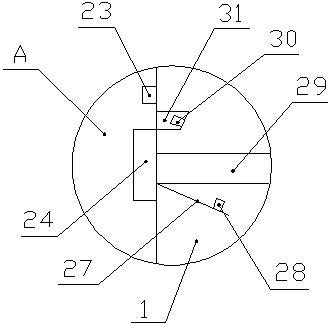

[0022] Such as Figure 1-6 As shown, a construction waste recycling device includes a box body 1, the upper end of the box body 1 is connected with a box cover 2, and the left side of the upper end of the box cover 2 is connected with a feed hopper 3, and the upper end of the box cover 2 is connected with a feed hopper 3, and the upper end of the box The hopper 3 passes through the box cover 2 and communicates with the box body 1. The upper part of the inner wall on the left side of the box body 1 is fixedly connected with an inclined plate 5, and the upper end of the inclined plate 5 is fixedly connected with a hook 4. The box body 1 Electromagnets 6 are symmetrically connected to the inner walls on the left and right sides. The electromagnets 6 are located below the inclined plate 5. Electromagnetic relays 23 are symmetrically installed on the left and right side walls of the box body 1. The left and right inner walls of the box body 1 Symmetrically connected with an electri...

Embodiment 2

[0025] Such as Figure 1-6 As shown, a construction waste recycling device includes a box body 1, the upper end of the box body 1 is connected with a box cover 2, and the left side of the upper end of the box cover 2 is connected with a feed hopper 3, and the upper end of the box cover 2 is connected with a feed hopper 3, and the upper end of the box The hopper 3 passes through the box cover 2 and communicates with the box body 1. The upper part of the inner wall on the left side of the box body 1 is fixedly connected with an inclined plate 5, and the upper end of the inclined plate 5 is fixedly connected with a hook 4. The box body 1 Electromagnets 6 are symmetrically connected to the inner walls on the left and right sides. The electromagnets 6 are located below the inclined plate 5. Electromagnetic relays 23 are symmetrically installed on the left and right side walls of the box body 1. The left and right inner walls of the box body 1 Symmetrically connected with an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com