Grinding cutter and food waste processor

A technology of knives and cutterheads, applied in the fields of grinding knives and food waste disposers, can solve the problems of reducing grinding efficiency, bad feeling, disharmony, etc., and achieve the effect of improving grinding effect, increasing residence time, and reducing abnormal risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

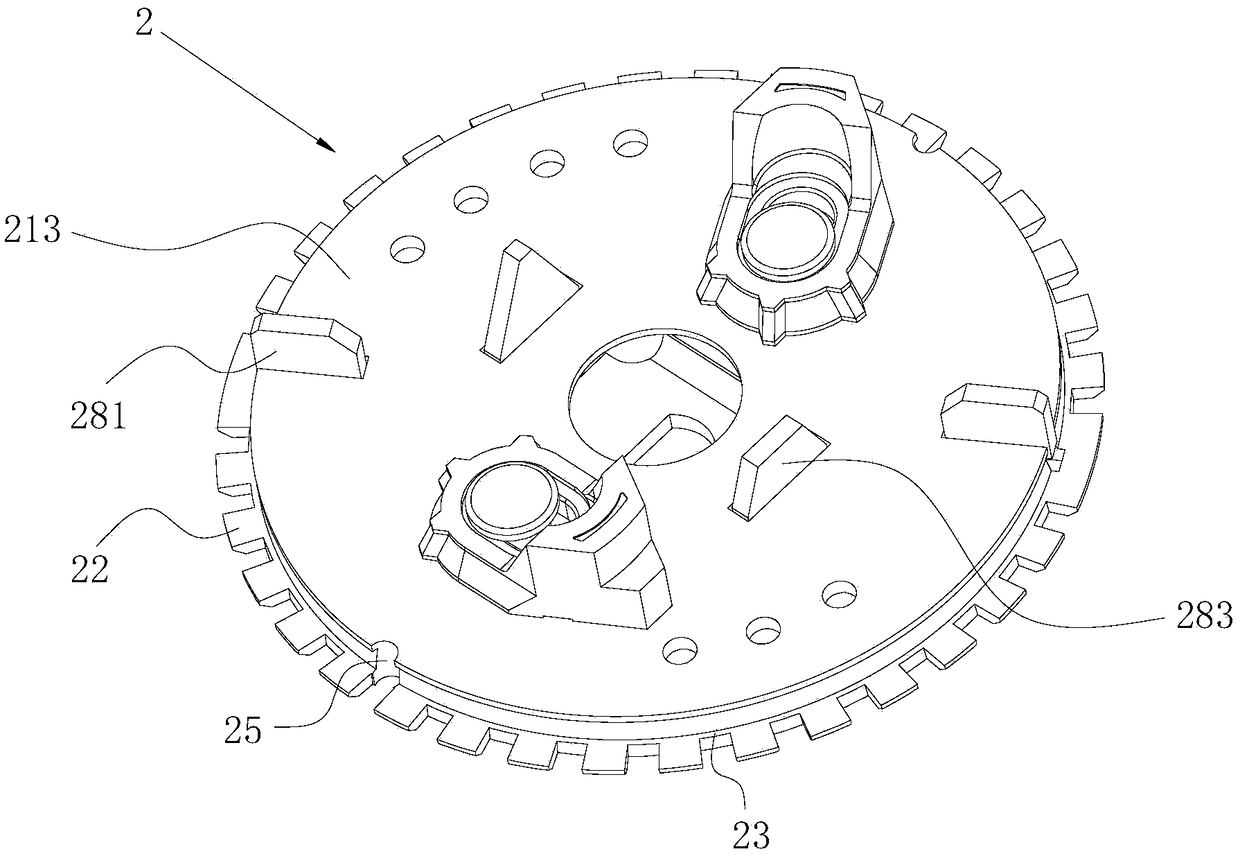

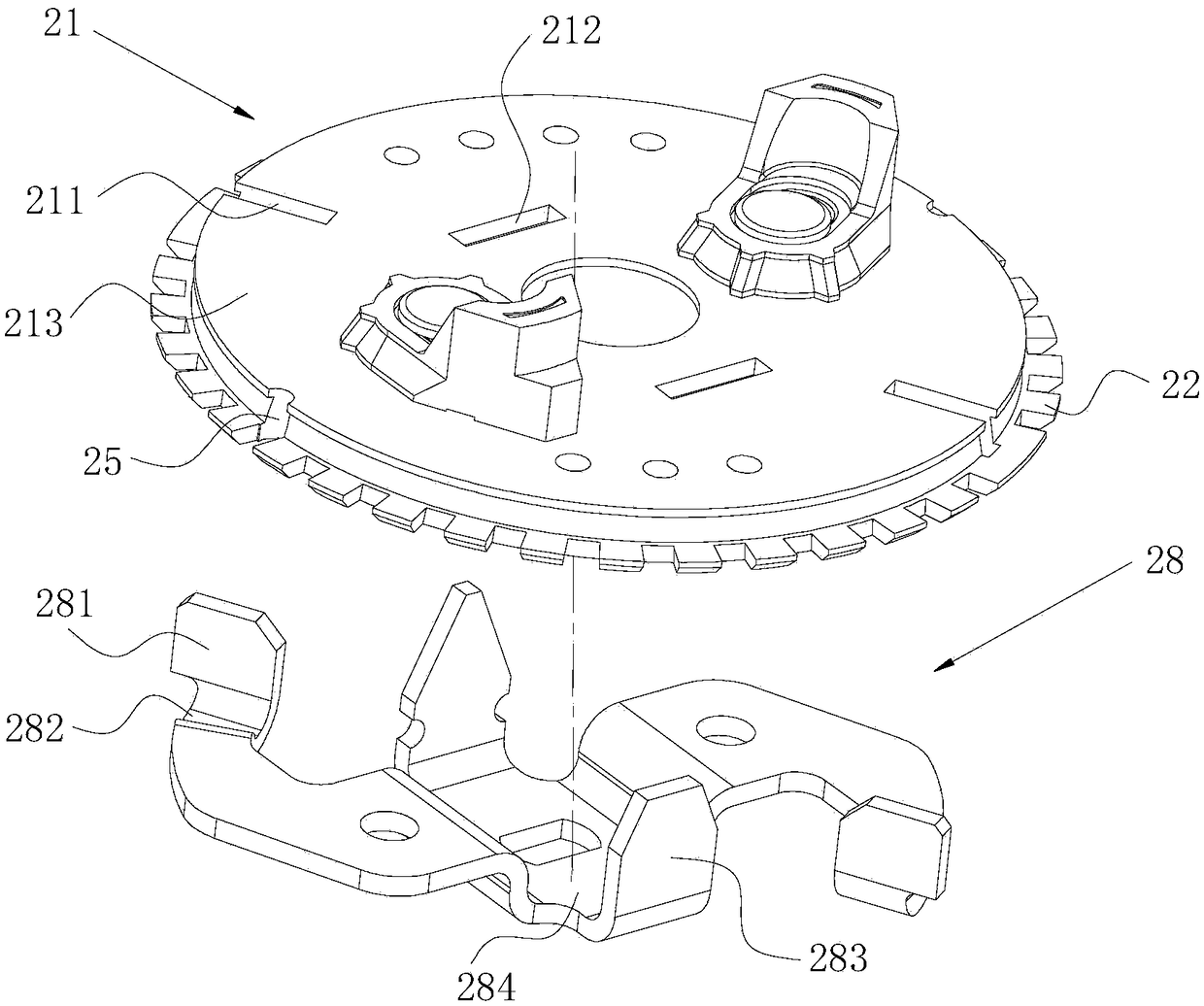

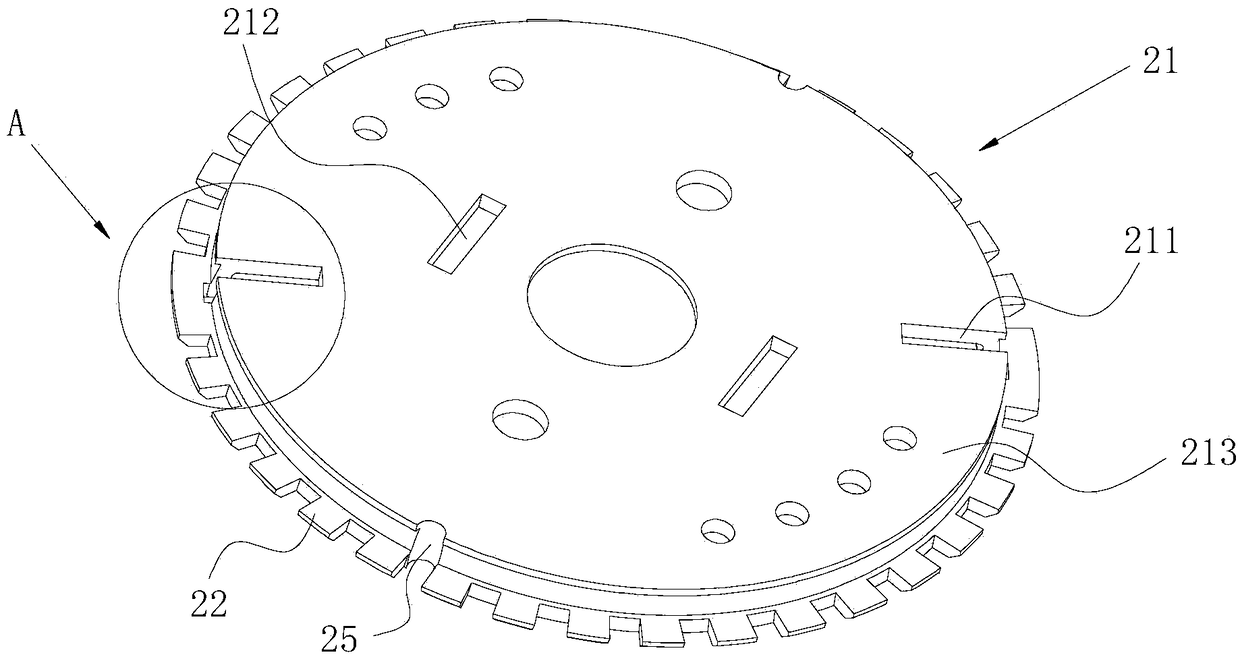

[0066] like Figure 1 to Figure 7 As shown, a grinding tool includes a fixed knife wall 1 and a rotating cutter head 2 installed at the inner lower end of the fixed knife wall 1. The rotating cutter head 2 includes a main body 21 and is arranged on the side wall of the main body 21. A plurality of working teeth 22, the working teeth 22 are arranged at equal intervals on the side wall of the main body 21, the working teeth 22 are located below the fixed knife wall 1, and between adjacent working teeth 22 An interdental boss 23 is arranged in the hollow part of the body, and the interdental boss 23 is formed extending radially outward along the side wall of the main body 21 . By arranging the interdental bosses 23, larger food waste particles can be prevented from directly passing through the gap between the rotating cutter head 2 and the fixed knife wall 1, thereby increasing the flow of food waste particles between the rotating cutter head 2 and the fixed knife wall 1. The re...

Embodiment 2

[0076] The difference between this embodiment and Embodiment 1 is:

[0077] like Figure 8 As shown, the line connecting the first corner line 231 of the interdental boss 23 and the edge of the top surface 213 of the main body 21 passes through the fixed knife wall 1. Such an overall design can ensure that food waste cannot be inserted into the fixed knife wall in a straight line. The gap between the above-mentioned working teeth 22 can more reliably reduce the abnormal risk of food waste being inserted into the gap between the working teeth 22 and rotate with the rotating cutterhead 2, thereby improving the crushing efficiency and reducing the risk of grinding. noise.

Embodiment 3

[0079] The difference between this embodiment and Embodiment 1 is:

[0080] like Figure 9 As shown, the upper surface of the annular groove 26 is inclined upward along the radially outward direction, and the distance between the outer edge of the upper surface of the annular groove 26 and the top surface 213 of the main body 21 is 1mm. Such a design can reduce the distance between the outer edge of the upper surface of the annular groove 26 and the top surface 213 of the main body 21, which is conducive to improving the shearing effect and efficiency of the suspended boss 27 on food waste, and can simultaneously Ensure that the root of the suspended boss 27 has good strength to avoid fracture.

[0081] In other embodiments, the distance between the outer edge of the upper surface of the annular groove and the top surface of the main body may also be 0.8 mm or 0.9 mm or 1.1 mm or 1.2 mm or 1.3 mm or 1.4 mm or 1.5 mm mm.

[0082] The "first" and "second" in this article are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com