Automatic punching and feeding mechanism for vehicle door guide rails

A feeding mechanism and automatic punching technology, applied in the field of auto parts, can solve the problems of easy deviation, inability to feed in place, poor grasping stability, etc., and achieve the effect of high degree of mechanization, good feeding stability and high working effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

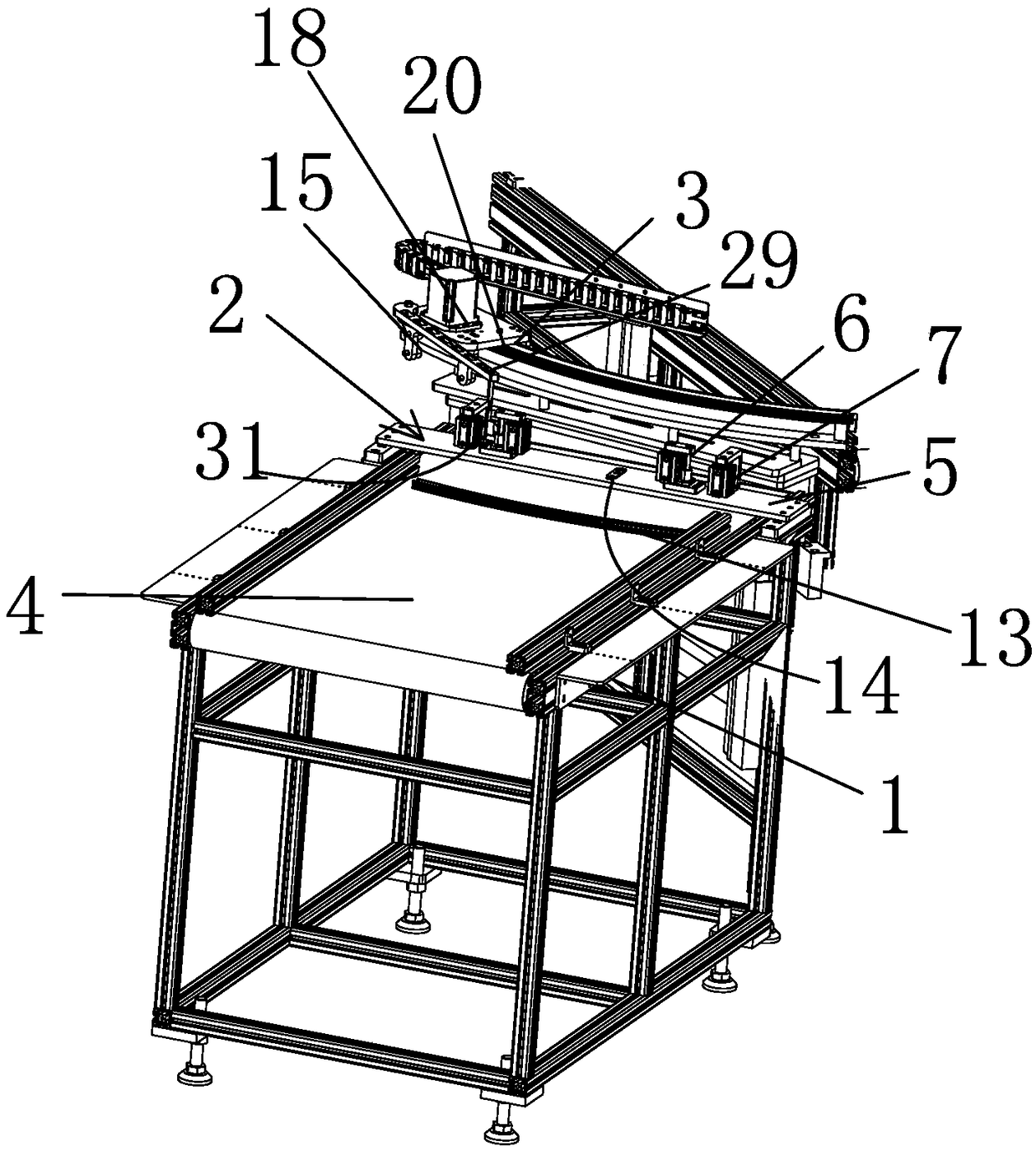

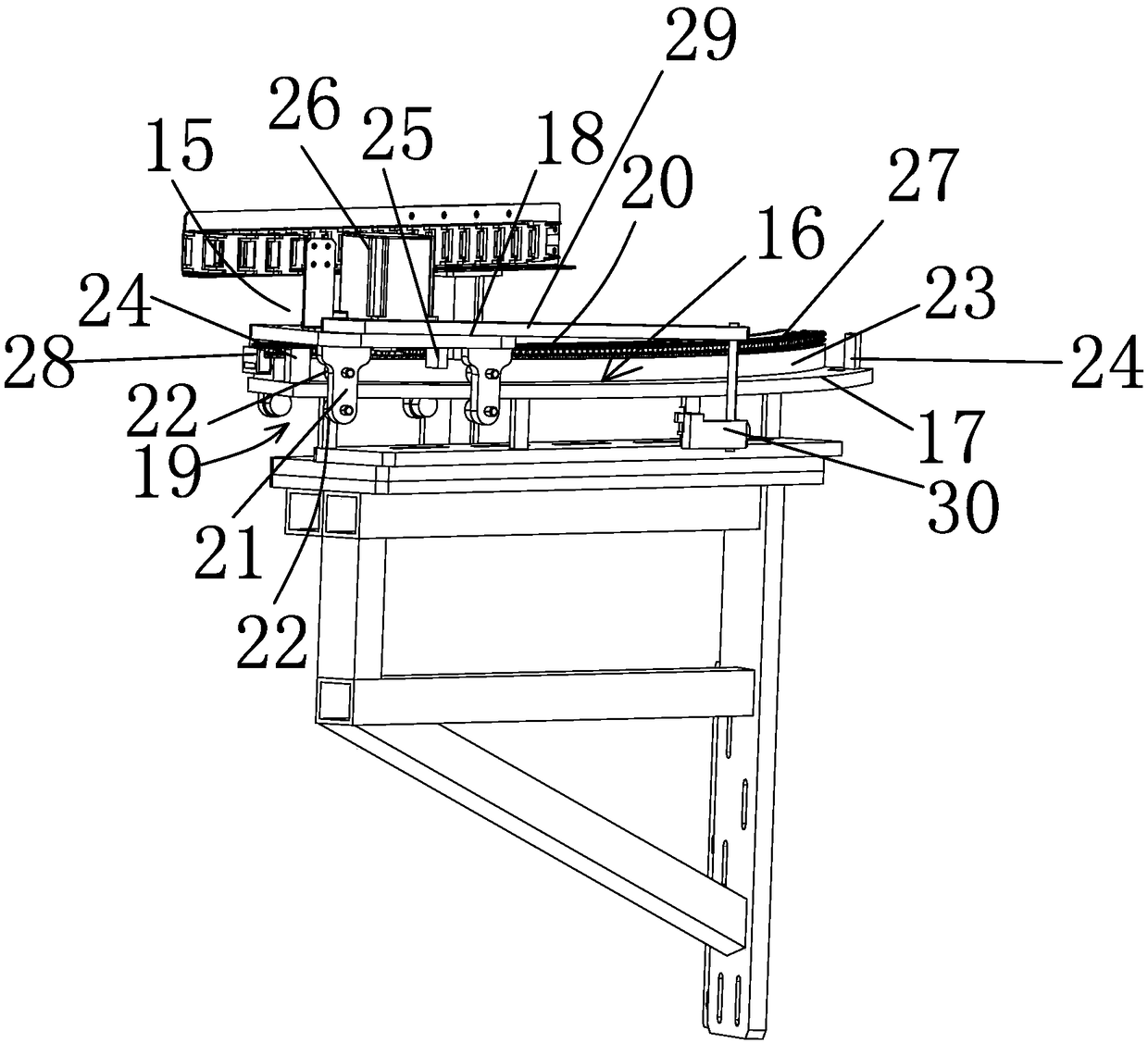

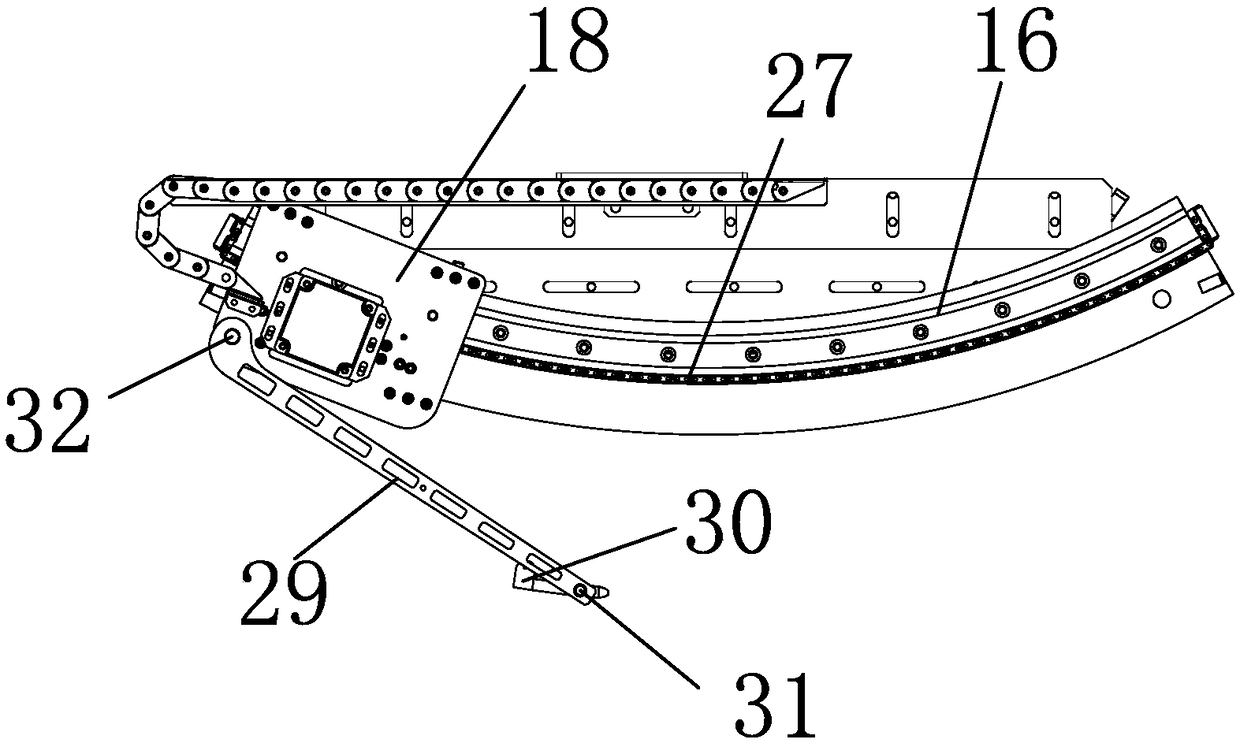

[0022] In the figure, conveyor table 1; guide rail sorting component 2; guide rail feeding component 3; conveyor belt 4; optical fiber support 5; guide rail pre-discharging mechanism 6; guide rail release mechanism 7; 10; guide shaft 11; release rod 12; door guide rail 13; sensor 14; push mechanism 15; guide plate 16; lower bottom plate 17; Cam bearing follower 22; guide arc groove 23; stop block 24; position limit block 25; push motor 26; push chain 27; tension block 28; connecting rod 29; push block 30; bearing stop pin 31; unloading screw 32.

[0023] Such as figure 1 as well as figure 2 As shown, the automatic punching and feeding mechanism for the door guide rail includes a conveying table 1, a guide rail sorting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com