Automatic aluminum profile saw cutting device

A technology for sawing devices and aluminum profiles, which is applied in the direction of sawing machine devices, metal sawing equipment, metal processing equipment, etc., and can solve problems such as affecting production and processing progress, lack of targeted automatic processing devices, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

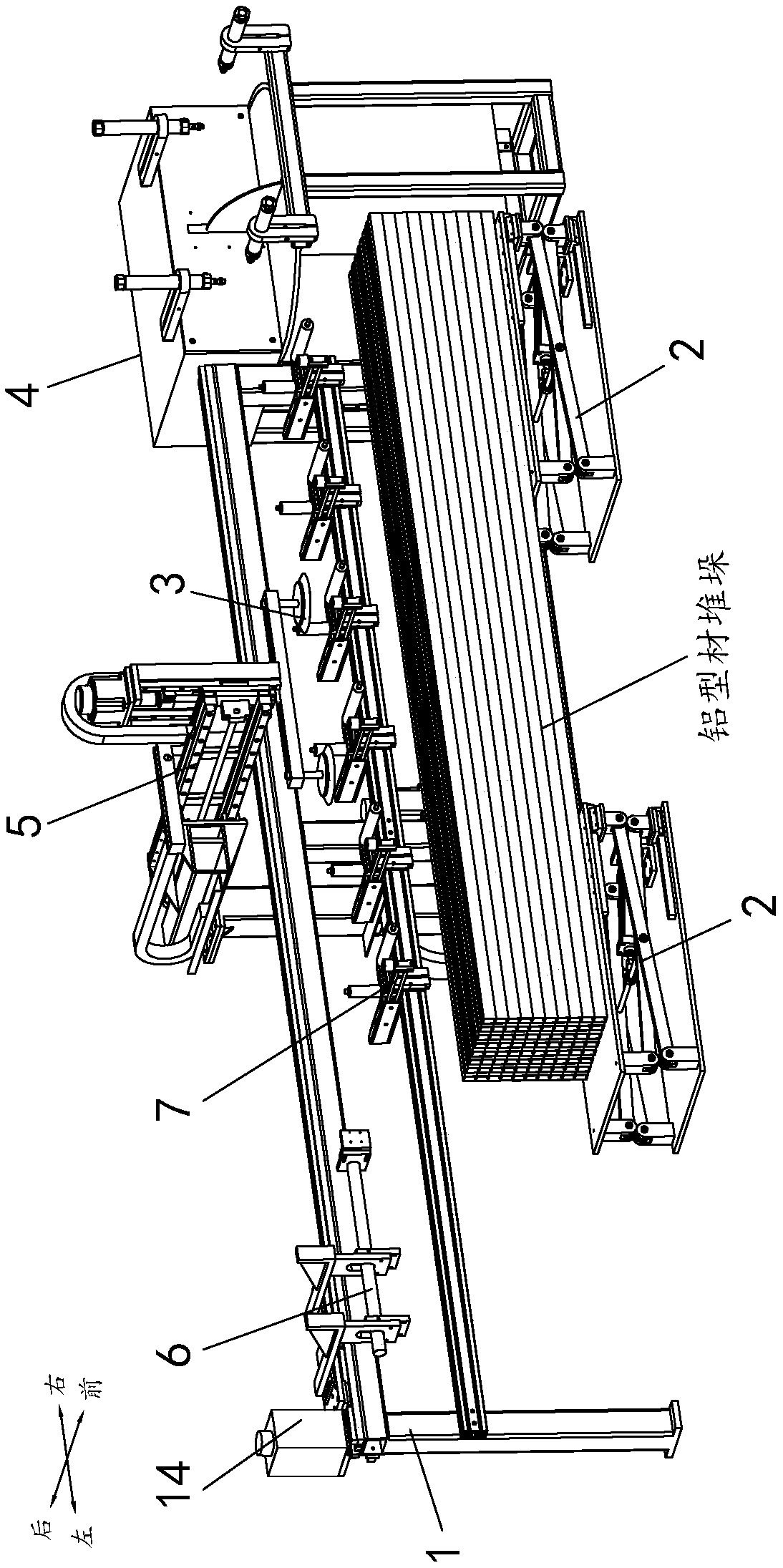

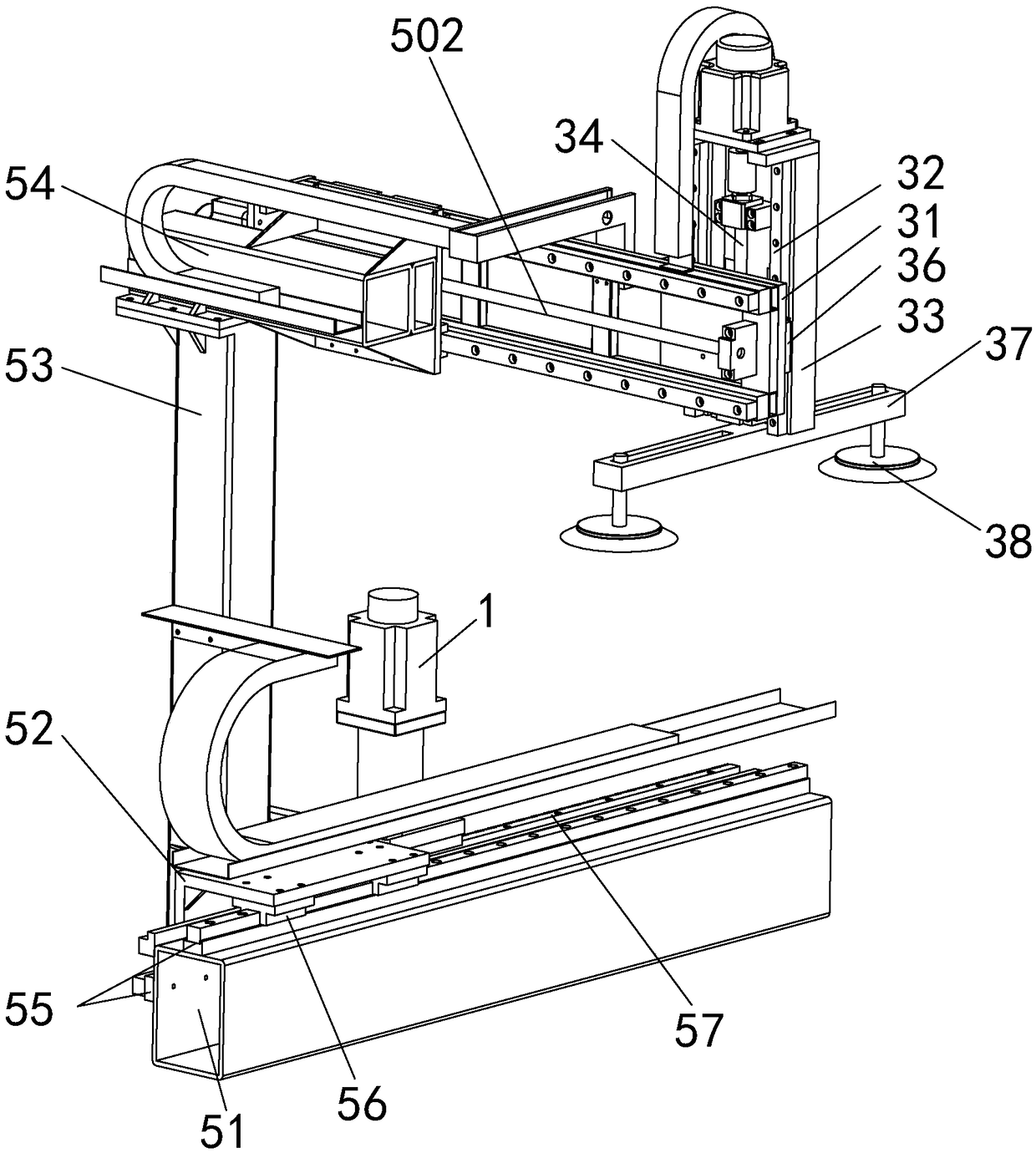

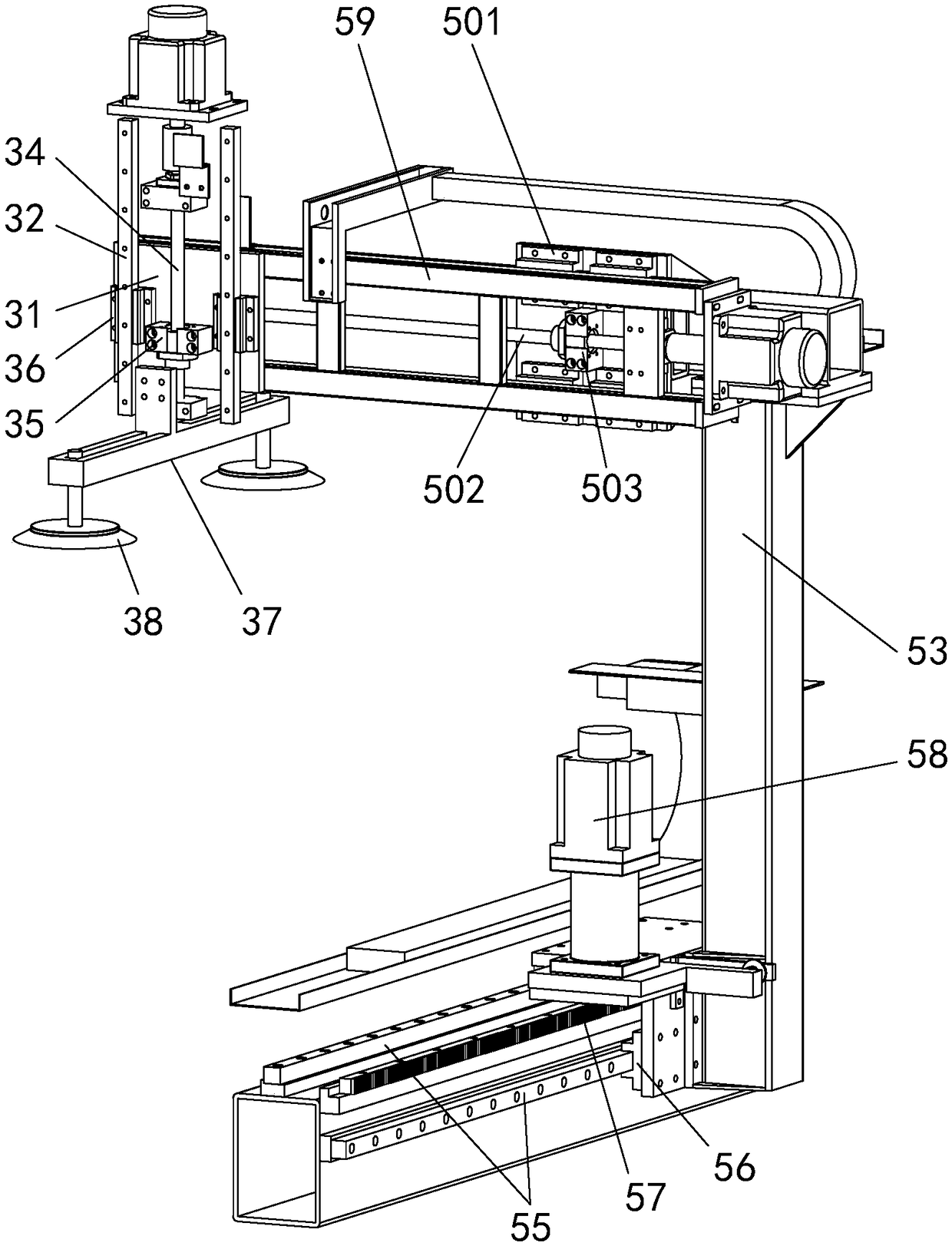

[0028] refer to figure 1 , an automatic aluminum profile sawing device, comprising a feeding frame 1, a lifting feeding mechanism 2 located at the front side of the feeding frame 1, a retrieving mechanism 3 located at the rear side of the feeding frame 1, and a The sawing device 4 on the right side of the frame 1; the reclaimer 3 is provided with a reclaimer 3 located above the feeder 2, and a displacement mechanism 5 for changing the position of the reclaimer 3; The feeding ejector rod 6 on the upper layer and the feeding roller assembly 7 arranged evenly on the lower layer, the feeding ejector rod 6 pushes the straight aluminum profile grabbed by the reclaiming mechanism 3 and placed on the feeding roller assembly 7 to the saw Cutting is carried out on the cutting device 4. In actual use, the straight aluminum profiles stacked on behalf of the processing can be placed on the feeding mechanism 2. The feeding mechanism 2 can select the quantity according to the length of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com