Special tool for simultaneous press fitting of checks rings on two sides of electromagnetic valve energy accumulator

A technology of accumulators and solenoid valves, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult assembly, large diameter of retaining ring, and difficult compression, etc., and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

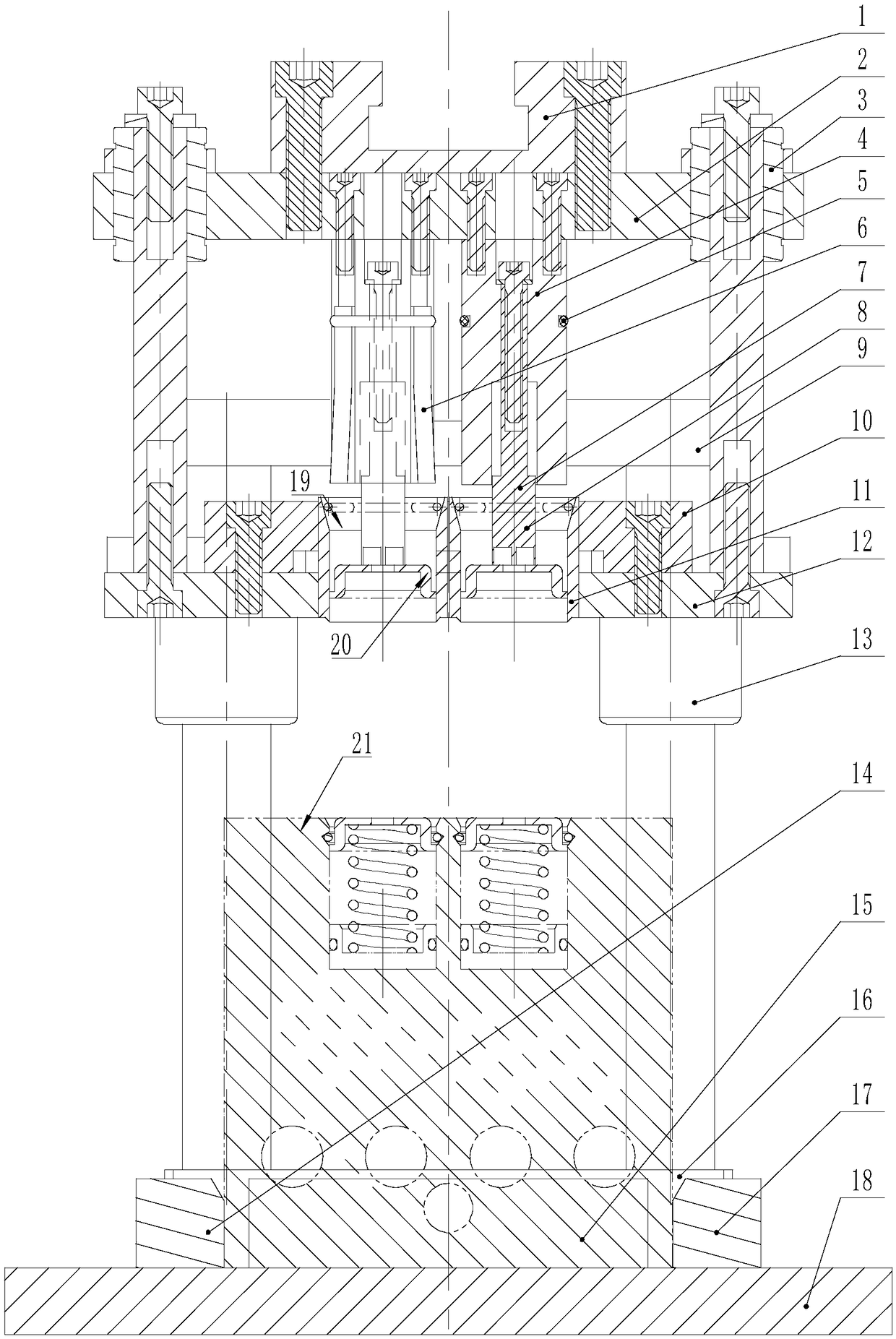

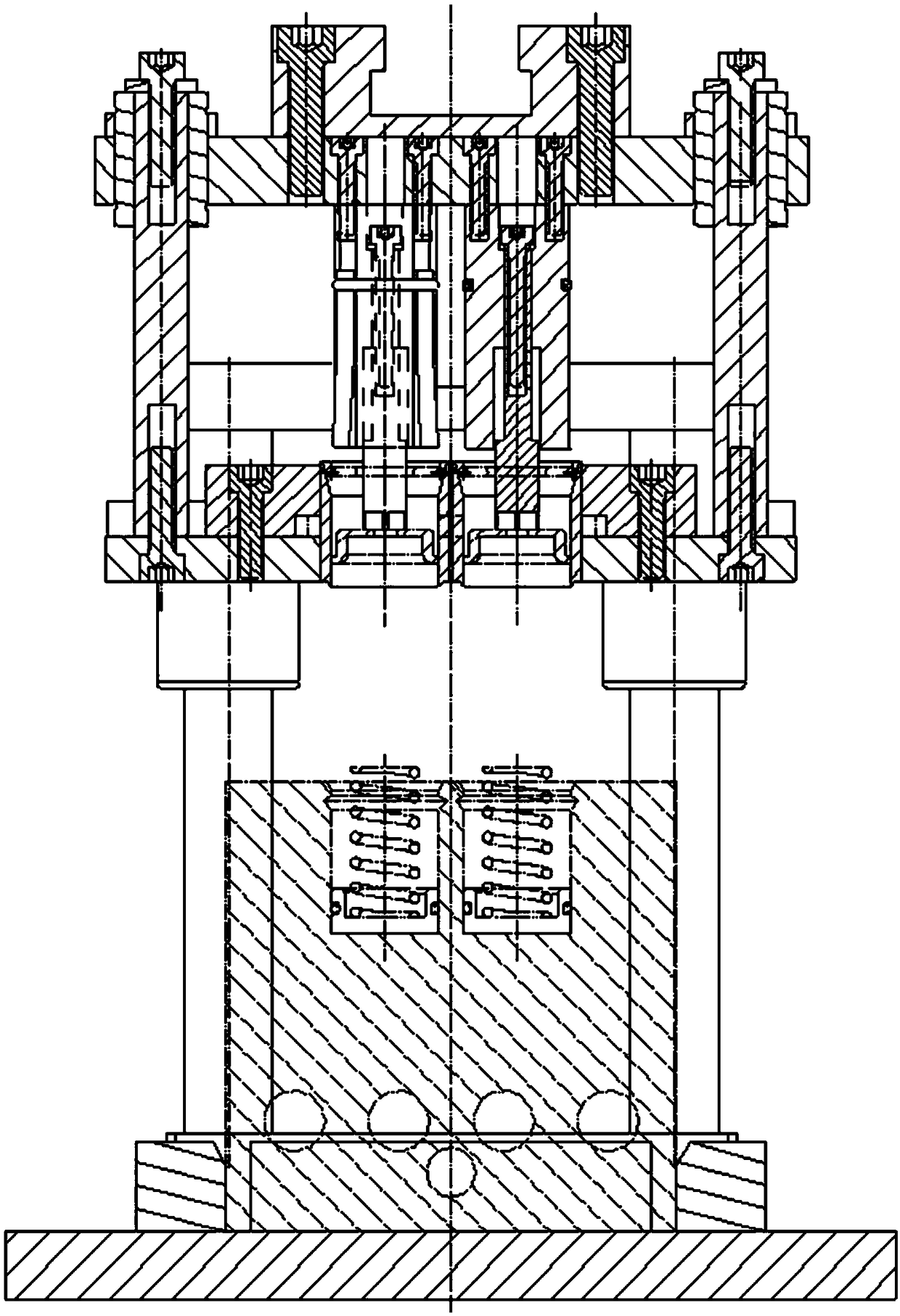

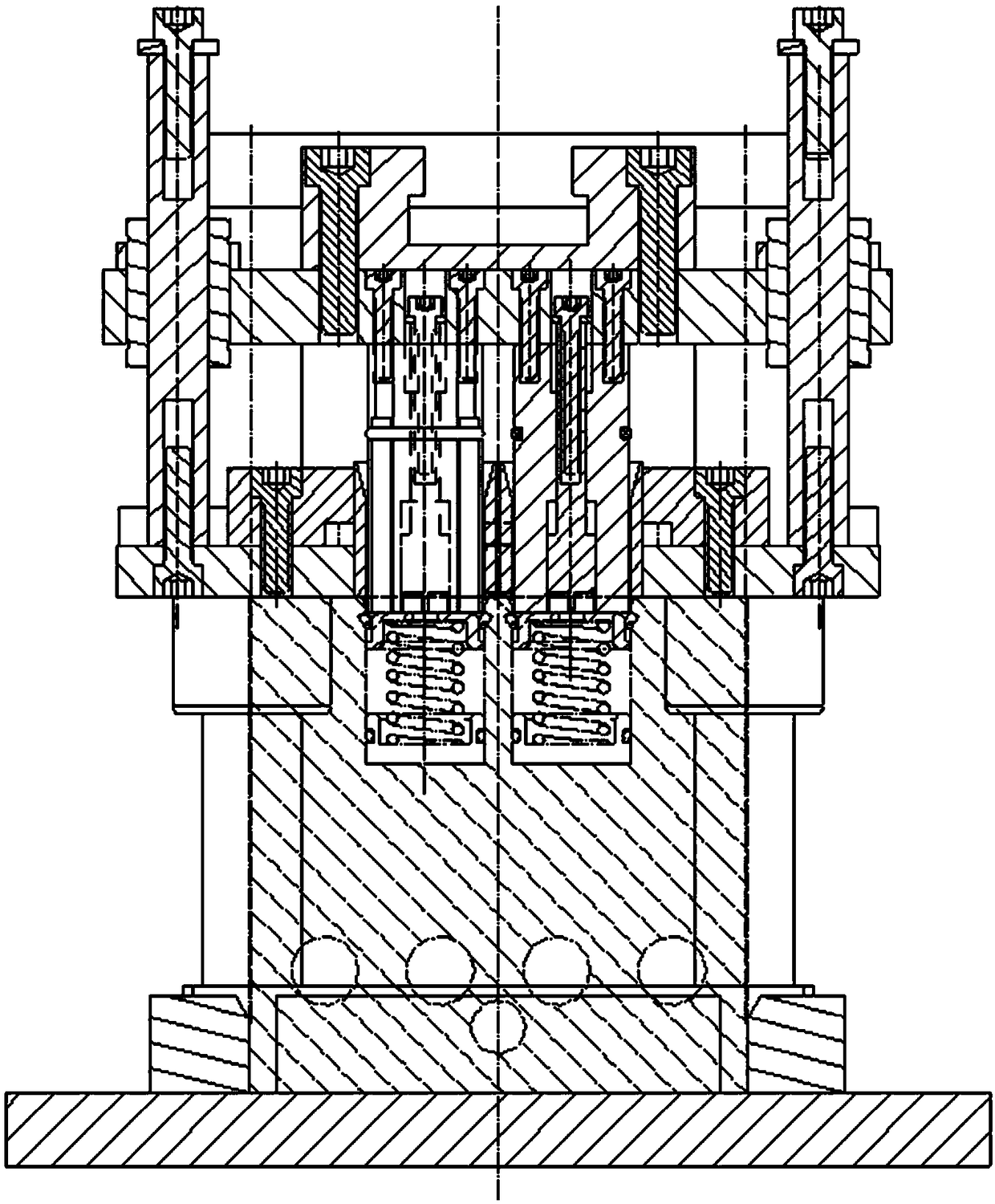

[0022] like figure 1 As shown, the special tooling of the present invention is used for the installation of retaining rings 19 and blocking covers 20 in the two accumulator holes on the main valve body 21 of the electromagnetic valve accumulator, and the middle part of the top surface of the main valve body 21 is provided with two An accumulator hole, the inner wall of the upper hole end of the accumulator hole is provided with an annular slot for inserting a retaining ring 19, including a tool mounting plate 2, an upper linear bearing 3, a press-fitting tool 4, a rubber ring 5, and claws 6. Blocking cover positioning core 7, magnet 8, bearing limit block 9, positioning sleeve pressure plate 10, positioning sleeve 11, positioning sleeve mounting plate 12, lower linear bearing 13, left limit block 14, rear limit block 15 , Bearing mounting block 16, right limit block 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com