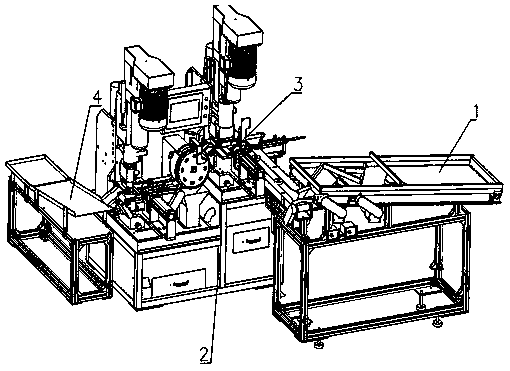

Precise multi-station automatic cutting equipment

A cutting equipment and multi-station technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as quality and speed not being improved, hidden dangers, and safety, and achieve novel structure and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0076] Embodiment 2: When the cutting device is a double station, the first cutting device and the second cutting device are installed on both sides of the turning disc transition mechanism, and the first cutting device cuts the product and transmits it to the turning disc transition mechanism to convert the product The waste material falls into the dust collection tank of the second frame box, and the product falls into the second cutting detection mechanism through the feeding gap, and then pushes, positions, clamps, drills, and cuts again, and passes through the second The transition assembly transfers the product onto the outfeed mechanism.

[0077] working principle:

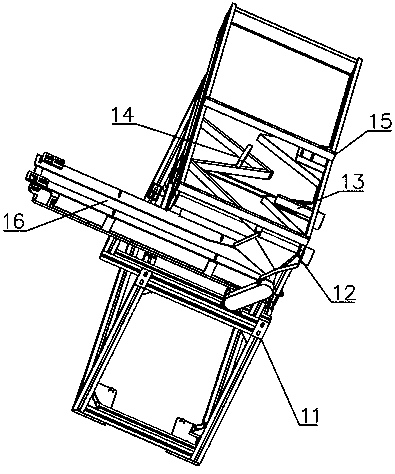

[0078] Put other products into the feeding mechanism. When multiple products are attracted to each other, they pass through the feeding screening baffle. Because the maximum distance between the feeding screening baffle and the feeding screening conveyor belt is the height of a magnetic ring, multiple magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com