Swing-type eccentric inner circle linkage grinding method

A swing-type, grinding technology, applied in grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, grinders, etc., can solve the problems affecting the machining accuracy of the workpiece, low machining efficiency, and large footprint Achieve the effect of avoiding the influence of machining accuracy, saving production costs and the number of grinding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

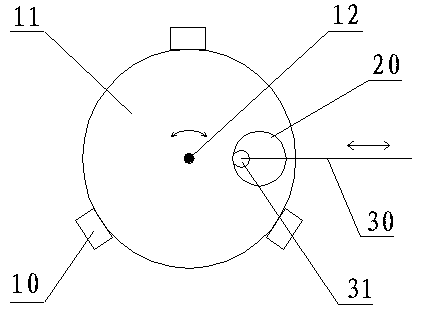

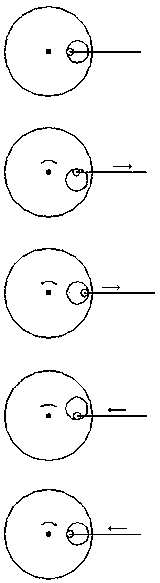

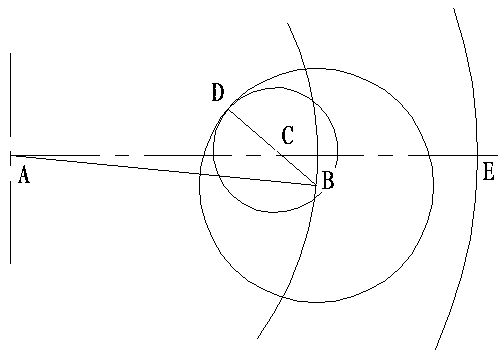

[0024] see figure 1 and figure 2 , the present invention grinds the eccentric inner circle in an X-C linkage manner. During the grinding process, the central axis of the workpiece 11 is used as the rotation axis (C axis) 12, and the workpiece rotation mechanism 10 (only the jaws are shown in the figure) ) drives the workpiece to swing around the C axis, and at the same time drives the abrasive tool 31 to reciprocate in the direction of the X axis in the eccentric inner hole 20 through the abrasive tool feeding mechanism 30. Both the workpiece and the abrasive tool move according to the prescribed path, and both move The synthesis of the grinding tool makes the grinding track of the grinding tool relative to the workpiece the same as the grinding track of the grinding tool relative to the workpiece in the prior art or achieves the same grinding effect, so that it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com