A pollution-free and environmentally friendly distiller's lees treatment method

A processing method and non-polluting technology, applied in the field of distiller's grain waste treatment and recycling, can solve the problems of inability to achieve continuous pressing work, uneven pressing of distiller's grains, unsatisfactory pressing effect, etc., and achieve green production environment, good pressing effect, and application of force uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

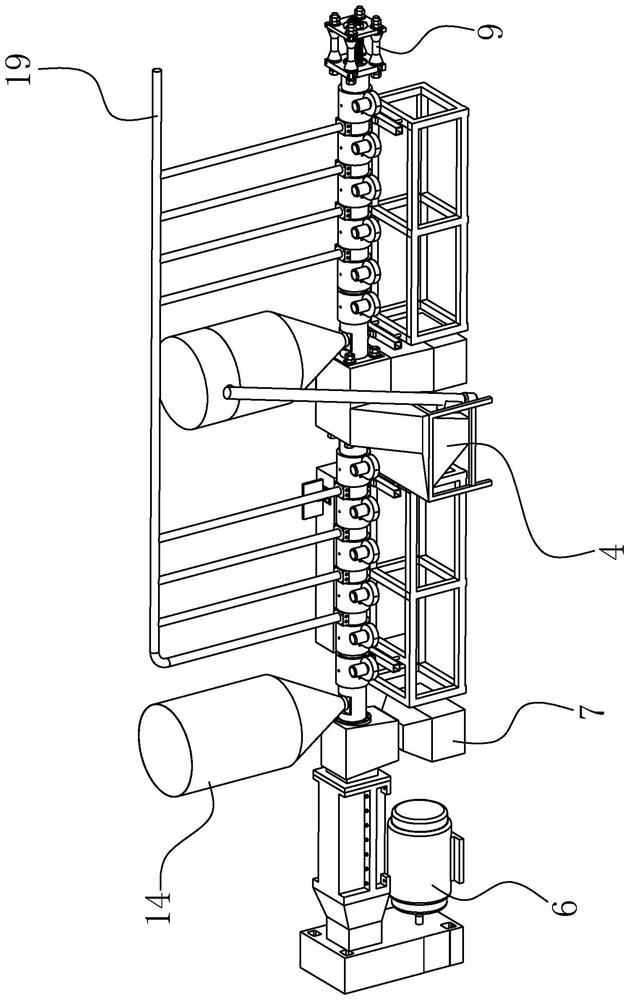

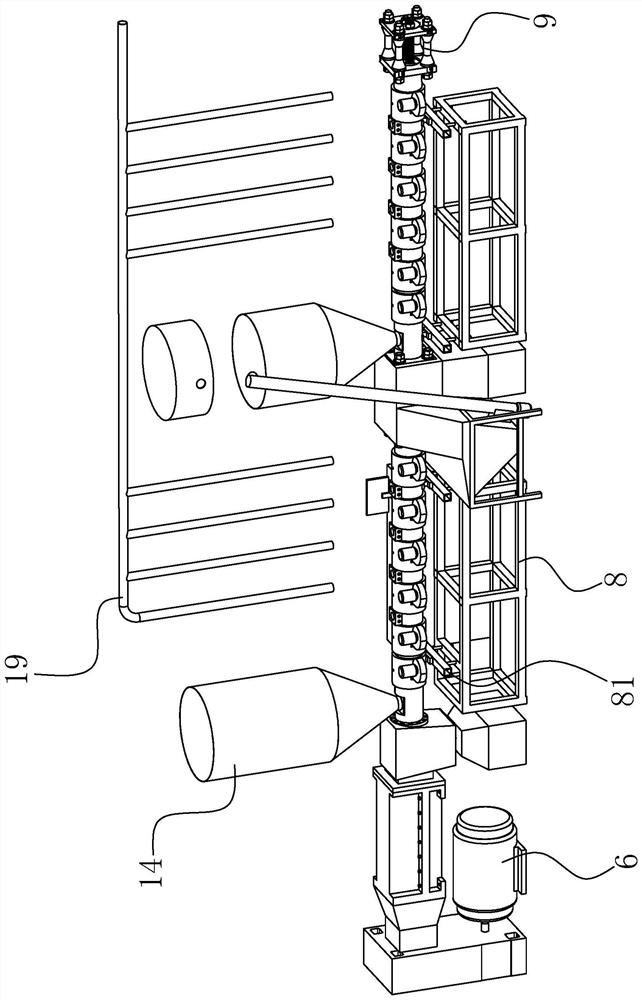

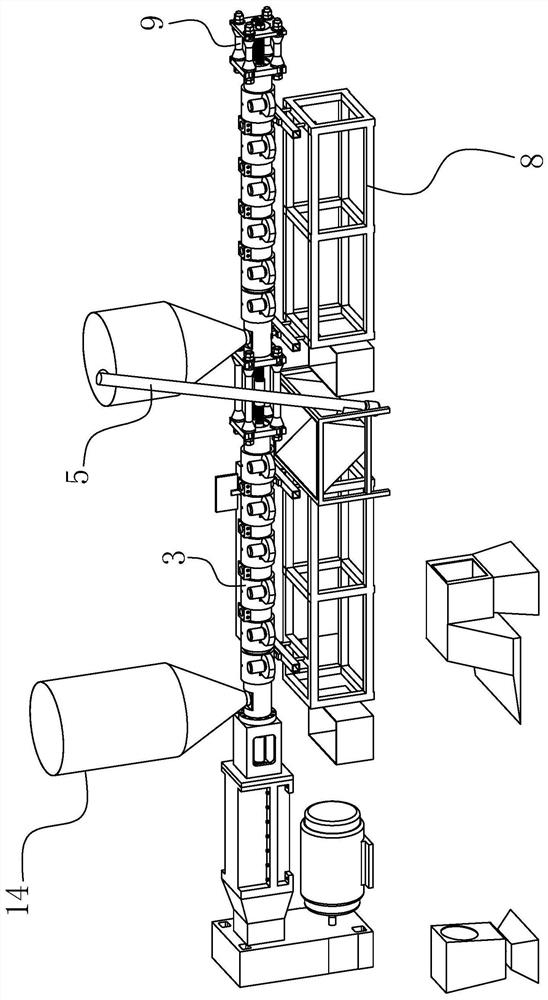

[0035] Such as Figure 1 to Figure 15 As shown, the pollution-free and environmentally friendly distiller's grains processing method of the present embodiment comprises the following steps:

[0036] 1. Input the distiller's grains into the barrel cavity of the distiller's grains processing device for extrusion;

[0037] 2. The twin-screws 2 in the distiller's grain processing device extrude the distiller's grains and transport the distiller's grains to the discharge port 12 of the distiller's grains processing device. The exhaust hole 13 of the distiller's grains processing device is discharged;

[0038]3. The suction device absorbs the steam and volatilized alcohol discharged from the exhaust hole 13 and recycles it;

[0039] 4. The dehydrated distiller's grains are transported from the discharge port 12 to the dehydration residue collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com