Aluminum roll loading box

A technology for loading boxes and aluminum coils, which is used in transportation and packaging, and containers and containers to prevent mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

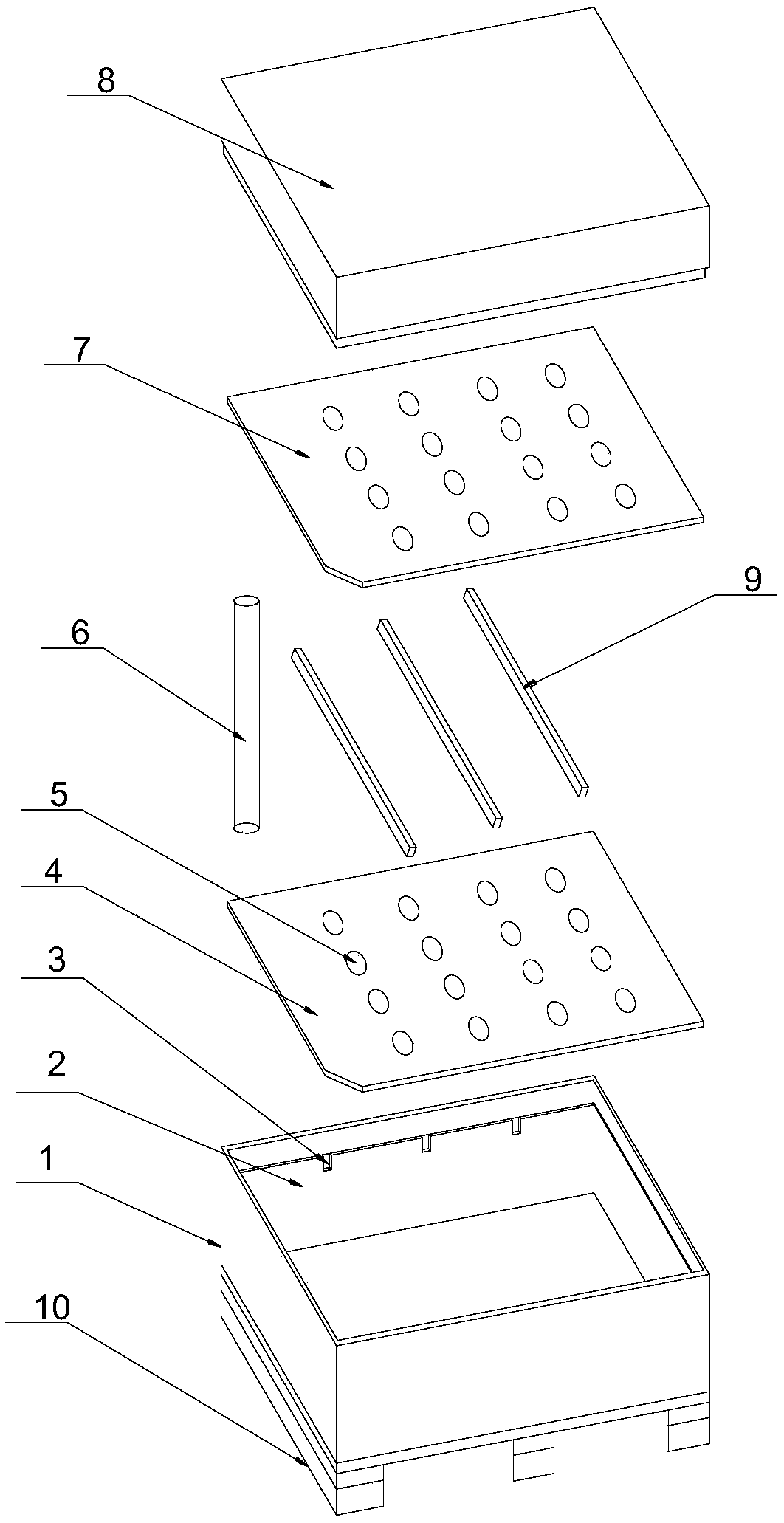

[0027] see figure 1 , an aluminum coil loading box, comprising a box body 1 with an open upper end, a box cover 8 is arranged above the box body 1, a first fixing plate 4 is arranged on the inner bottom of the box body 1, and the first fixing plate 4 is uniformly A plurality of sets of through holes 5 are provided, and load-bearing plates 2 are provided on the inner walls around the box body 1. A reel 6 is set inside the through holes 5, and a second fixing plate 7 is set on the upper part of the reel 6. , the second fixing plate 7 is provided with a plurality of sets of through holes 5 corresponding to the first fixing plate 4 , and the lower surface of the second fixing plate 7 is connected to the bearing plate 2 in conflict.

[0028] In the present invention, first install the first fixing plate into the bottom of the box, and then insert the reel into the through hole of the first fixing plate. At this time, the aluminum coils can be placed on each reel. When the height r...

Embodiment 2

[0031] see figure 1 , an aluminum coil loading box, comprising a box body 1 with an open upper end, a box cover 8 is arranged above the box body 1, a first fixing plate 4 is arranged on the inner bottom of the box body 1, and the first fixing plate 4 is uniformly A plurality of sets of through holes 5 are provided, and load-bearing plates 2 are provided on the inner walls around the box body 1. A reel 6 is set inside the through holes 5, and a second fixing plate 7 is set on the upper part of the reel 6. , the second fixing plate 7 is provided with a plurality of sets of through holes 5 corresponding to the first fixing plate 4 , and the lower surface of the second fixing plate 7 is connected to the bearing plate 2 in conflict.

[0032] The upper end of the opposite load-bearing bar 9 in the box body 1 is provided with a groove 3, and the load-bearing bar 9 is arranged in the groove 3 and is movably connected. The upper surface of the load-bearing bar 9 is flush with the upper...

Embodiment 3

[0038] see figure 1 , an aluminum coil loading box, comprising a box body 1 with an open upper end, a box cover 8 is arranged above the box body 1, a first fixing plate 4 is arranged on the inner bottom of the box body 1, and the first fixing plate 4 is uniformly A plurality of sets of through holes 5 are provided, and load-bearing plates 2 are provided on the inner walls around the box body 1. A reel 6 is set inside the through holes 5, and a second fixing plate 7 is set on the upper part of the reel 6. , the second fixing plate 7 is provided with a plurality of sets of through holes 5 corresponding to the first fixing plate 4 , and the lower surface of the second fixing plate 7 is connected to the bearing plate 2 in conflict.

[0039]At least one corner of the first fixing plate 4 and the second fixing plate 7 is chamfered with an obtuse angle.

[0040] In this embodiment, during the disassembly process, the obtuse angles of the first fixing plate and the second fixing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com