Metallic skirt capable of being integrally wound with glass fiber reinforced plastics tank and installation method of metallic skirt

A technology of glass fiber reinforced plastics and skirts, which is applied in the mechanical field, can solve problems such as poor results, and achieve the effects of easier guarantee of docking accuracy, saving crane costs, and reducing the difficulty of installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

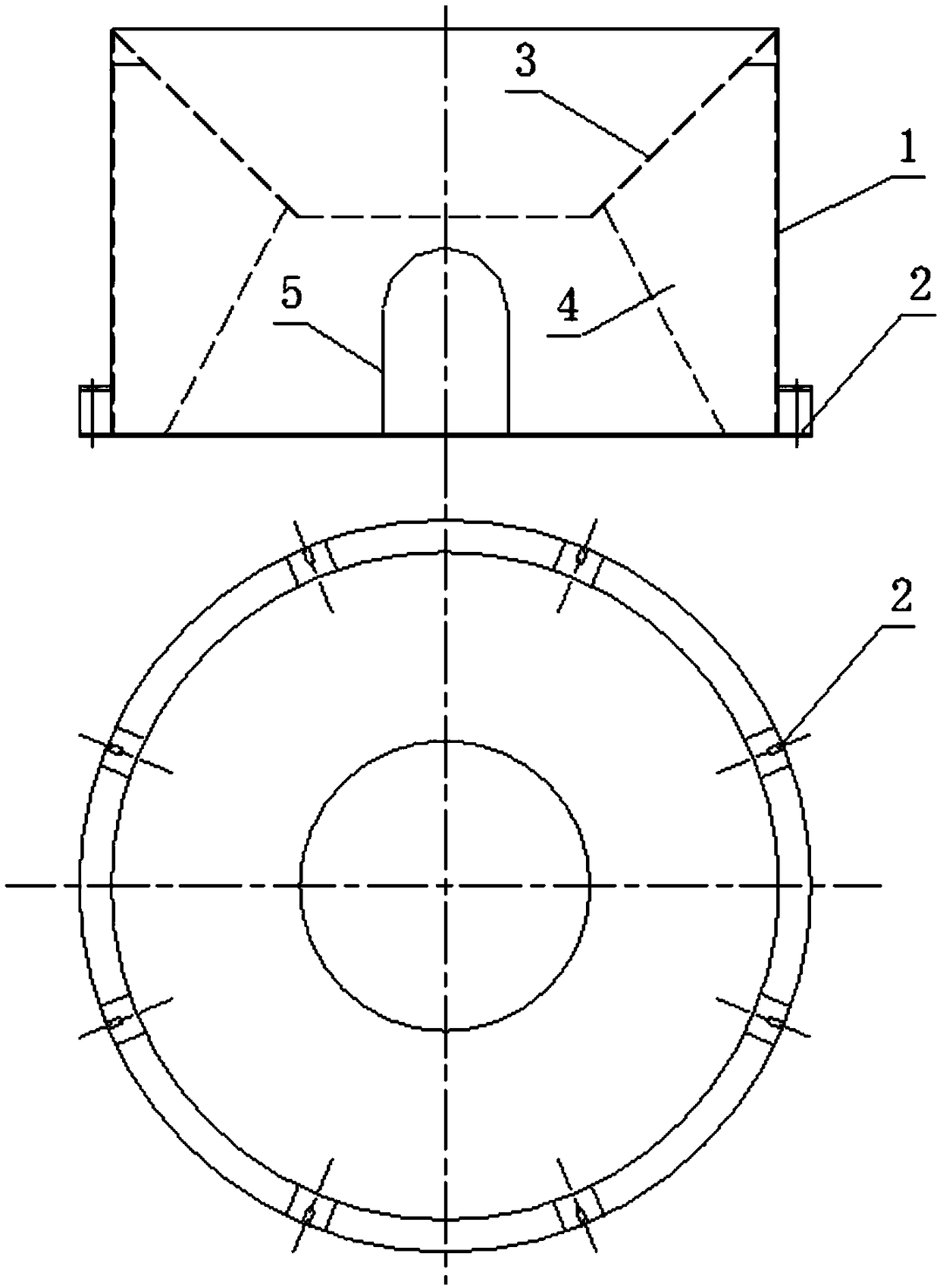

[0016] A metal skirt integrally wound with a glass fiber reinforced plastic tank, which includes: a skirt cylinder, a skirt bottom plate, a skirt cone and a supporting rib, and the skirt cylinder, skirt bottom plate and skirt cone The support ribs are welded into one body, the skirt bottom plate has anchor bolt holes, and the skirt cylinder has manholes for inspection.

[0017] The installation method of the above-mentioned metal skirt includes the following steps:

[0018] (1) The head of the FRP base is installed inside the metal skirt, and the head of the FRP base is bonded and fixed to the cone of the skirt;

[0019] (2) The skirt bottom plate is installed with a winding bracket;

[0020] (3) The glass fiber reinforced plastic base head with metal skirt is horizontally docked with the glass fiber reinforced plastic tank;

[0021] (4) The glass fiber reinforced plastic tank body and the metal skirt seat are controlled by a computer and are wound and reinforced as a whole....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com