Drip irrigation belt collecting mechanism and full-automatic drip irrigation belt recovering machine

A picking mechanism and drip irrigation belt technology, applied in agricultural machinery and implements, conveyors, loaders, etc., can solve the problems of easy to miss, affecting the continuity of operations, and low success rate of picking up drip irrigation belts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

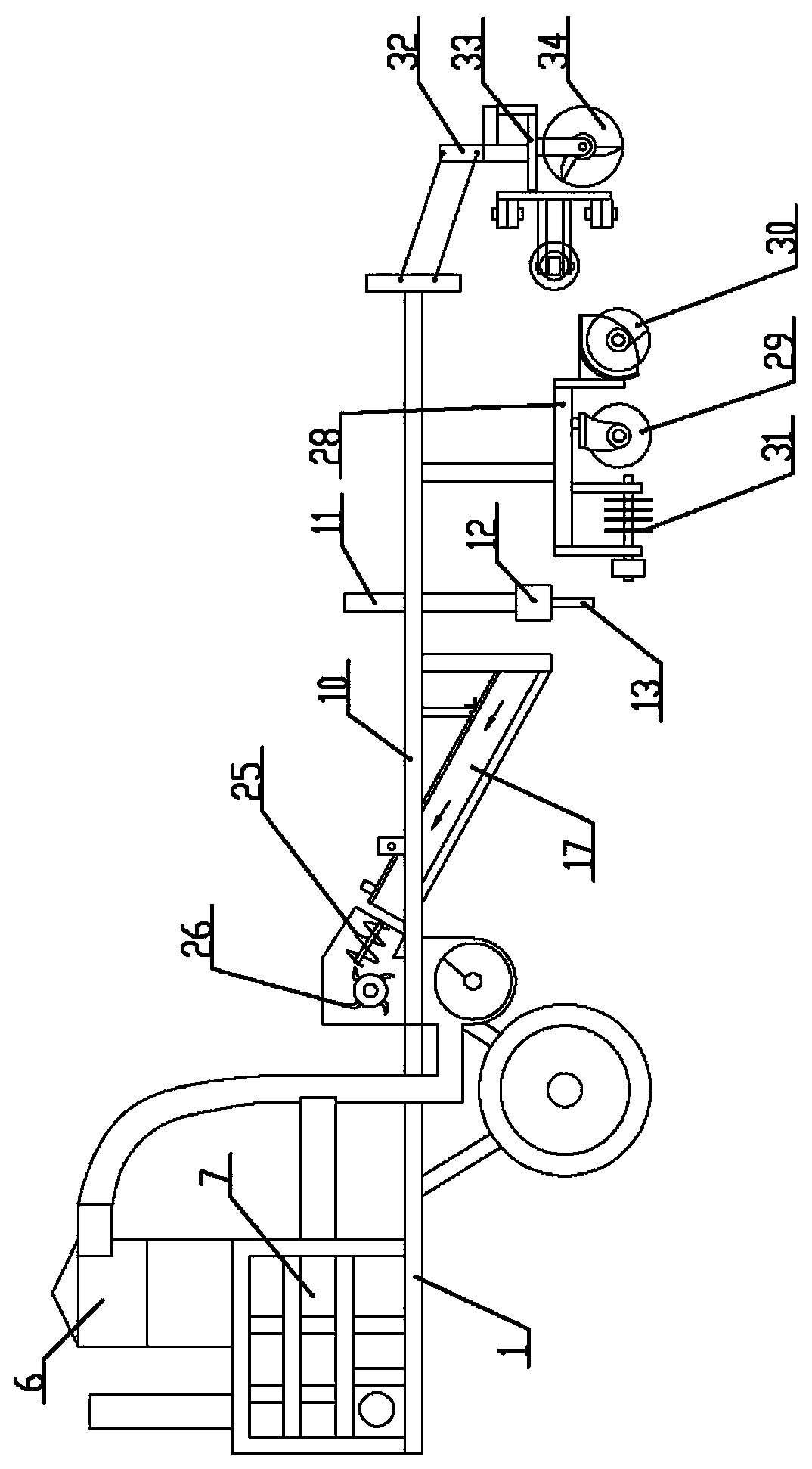

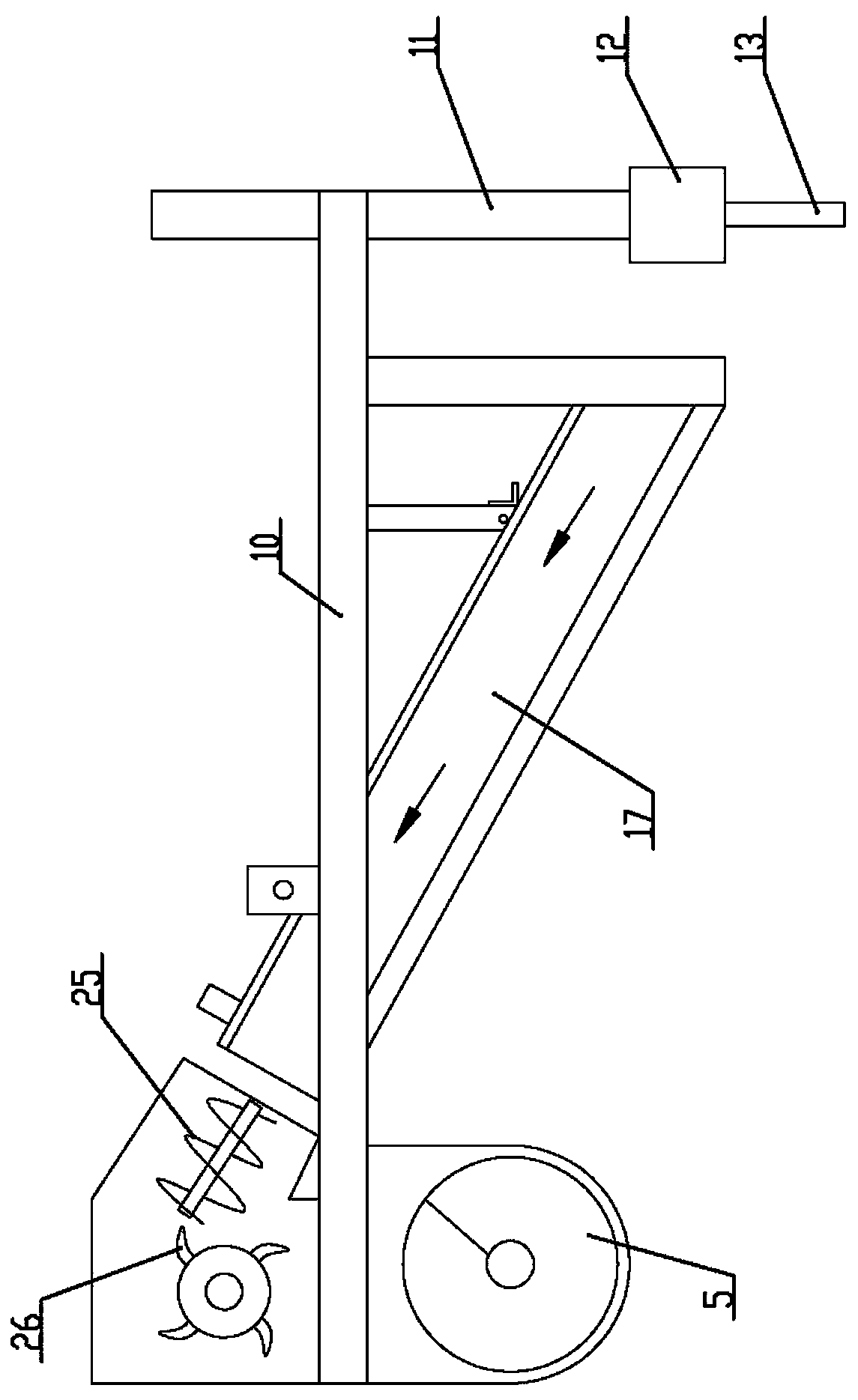

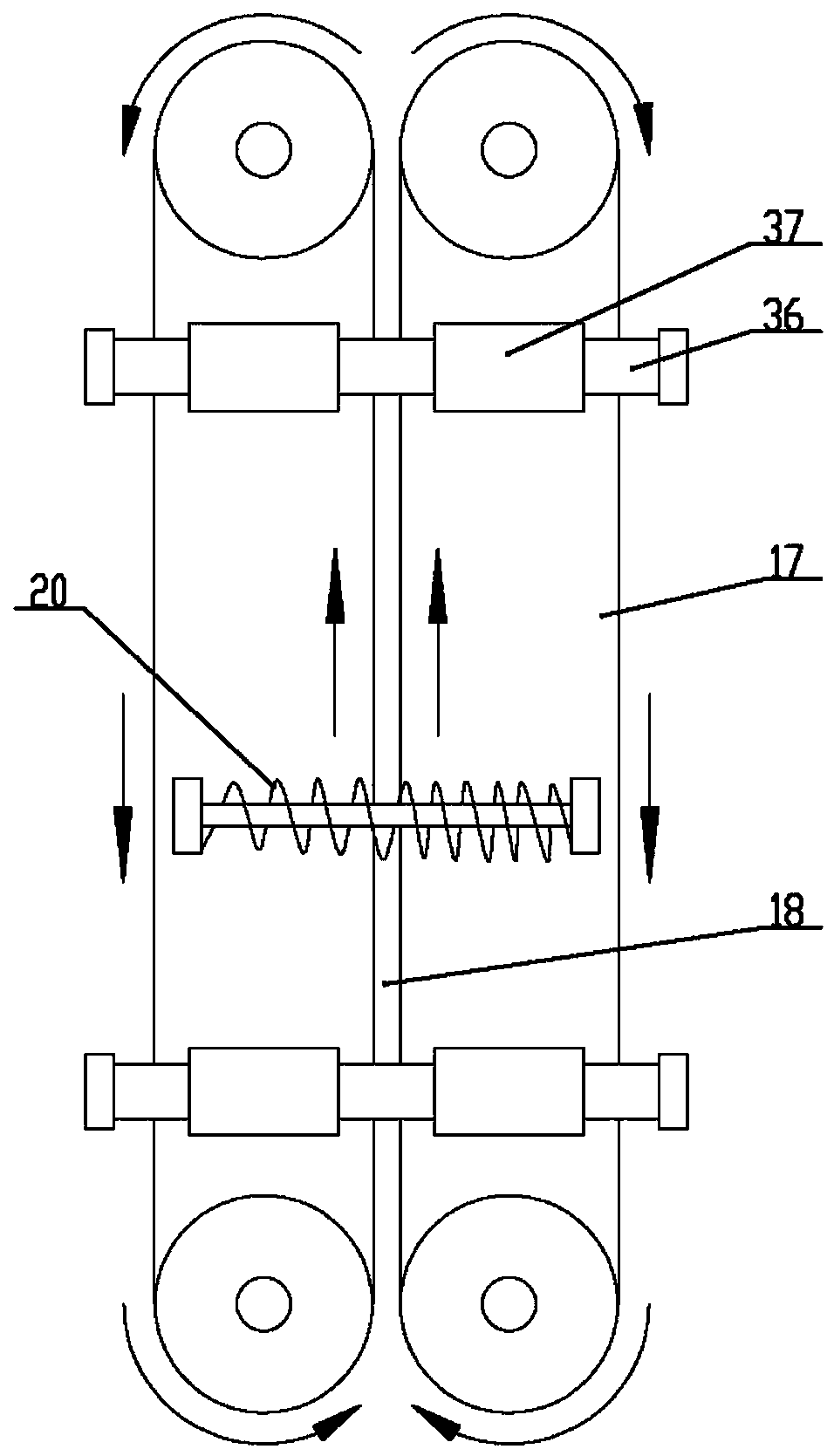

[0033] Embodiment one: refer to Figure 1 to Figure 10 , the structure schematic diagram of the first embodiment of the present invention is a fully automatic drip irrigation tape recovery machine, including a main frame 1, a transmission mechanism, and a drip irrigation tape collection mechanism. The main frame 1 is provided with at least one set of drip irrigation tape pick-up mechanisms.

[0034] The main frame 1 is provided with more than two groups of drip irrigation tape picking mechanisms, which are connected to the main frame 1 through the suspension beam 2. The suspension beam 2 is a sliding bar, and more than two groups of drip irrigation tape picking mechanisms can move on the sliding bar. The slider is connected to the suspension beam, and the drip irrigation belt pick-up mechanism is provided with a lateral propulsion mechanism between the adjacent drip irrigation belt pick-up mechanisms, and the drip irrigation belt pick-up mechanism lateral propulsion mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com