Tip device with large radial bearing force

A bearing capacity, top-notch technology, applied in the direction of transportation and packaging, winding strips, thin material processing, etc., can solve the problem of limited maximum tape weight of the reel of the tape winding machine, huge loss of strip waste, and inability to wind simultaneously, etc. problem, to achieve the effect of simple structure, increased tape weight, and reduced number of roll changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

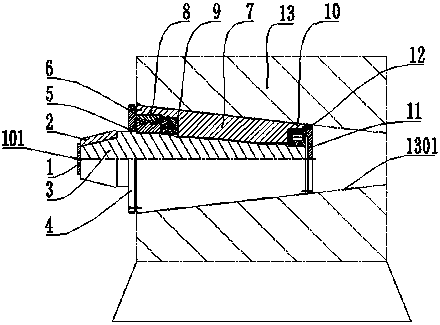

[0031] Such as figure 1 As shown, the present invention provides a tip device with a large radial bearing capacity, including a tip unit and a tip seat 13, and the tip unit is installed on the tip seat 13; the tip unit includes a rotating assembly, a connecting assembly, and a sealing and pressing assembly; The rotating assembly and the connecting assembly are pressed and sealed by pressing the sealing assembly.

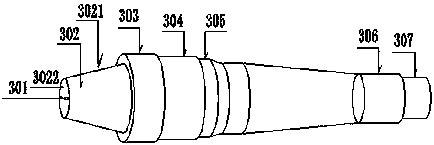

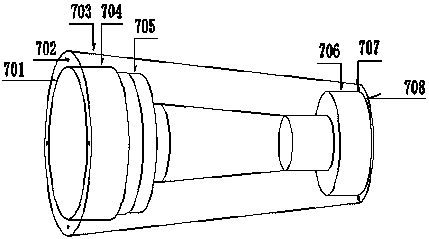

[0032] Such as figure 1 and figure 2 Commonly shown, the rotating assembly includes a top core 3, a first bearing 8, a second bearing 9 and a third bearing 10; the top core 3 is a cylinder, and the top core 3 is sequentially provided with a top core threaded hole 301, The head 302, the first shoulder 303, the first bearing installation area 304, the second bearing installation area 305, the third shaft shoulder 306, and the third bearing installation area 307; the head 302 is provided with a head Morse taper surface 3021 and head front end surface 3022; the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com