Preparation method for mica paper with high strength, insulation and high temperature resistance

A technology of high temperature resistance and mica paper, which is applied in the field of mica paper, can solve the problems of insufficient impact resistance, heat resistance of mica paper, poor insulation, easy fracture of mica paper, etc., and achieve the effect of improving toughness and broad application prospects

Inactive Publication Date: 2019-01-18

FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The technical problem to be solved by the present invention is to provide a high-strength insulating and high-temperature-resistant mica paper for mi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

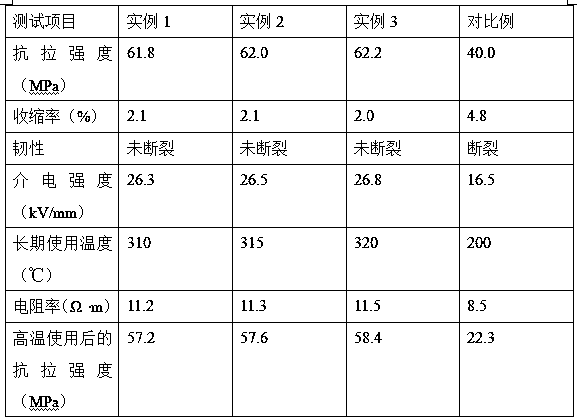

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a preparation method for a mica paper with high strength, insulation and high temperature resistance and belongs to the technical field of mica paper. The preparation method comprises the following steps: soaking a bamboo piece in acid liquor and alkali liquor in turn, thereby separating bamboo fibers from the bamboo piece; taking cells and interstitial fluid from bamboo fibers; utilizing high-pressure hydrolysis to decompose cellulose and xylogen in bamboo fibers into organic acid and furfural substances, wherein bamboo fibers have certain toughness and the toughnessand mechanical strength of bamboo fibers are further enhanced by introducing metallic oxides into the surface. According to the invention, the modified bamboo fibers are mixed with ethyl orthosilicate; when the paper sheet is soaked, deionized water is added and reacts with ethyl orthosilicate, so as to generate silicon dioxide; silicon dioxide is bonded with bamboo fibers and mica powder, so thatthe excellent mechanical properties, insulation and high temperature resistance of bamboo fibers and silicon dioxide are utilized to promote the toughness, insulation and high temperature stability of mica paper; the preparation method has a broad application prospect.

Description

technical field [0001] The invention relates to a preparation method of high-strength insulating and high-temperature-resistant mica paper, which belongs to the technical field of mica paper. Background technique [0002] Mica is a general term for a class of hydrous aluminosilicates. Mica paper is made of high-quality muscovite in Sichuan, which is broken into pulp paper by thermochemical or hydraulic stripping, and then cut into continuous roll paper or sheet paper. . Mica has excellent properties such as insulation and high temperature resistance, and is widely used in coatings, paints, fire protection and electrical industries. Among them, making mica into mica paper is one of the most widely used mica applications. [0003] At present, mica paper has all the varieties corresponding to sheet mica products. The industry mainly uses the insulation and heat resistance of mica paper, as well as its acid and alkali resistance, to be used as insulating materials for electri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21H27/00D21B1/02D21H19/64D21H19/52D21H19/40D21H19/38

CPCD21B1/021D21H19/385D21H19/40D21H19/52D21H19/64D21H27/00

Inventor 刘菊花蒋东明王素香

Owner FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com