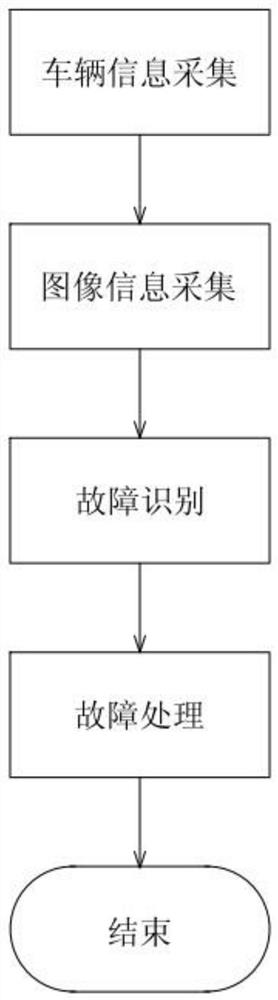

Dynamic image detection equipment and detection method for truck running faults

A technology of running faults and dynamic images, applied in the direction of railway vehicle testing, etc., can solve problems such as errors in detection results, and achieve the effects of improving accuracy, optimizing operation steps, and improving detection stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] The dynamic image detection device for truck running faults of the present invention includes a computer, a wheel sensor, an automatic identification server and a 3D image acquisition module;

[0017] The device of the present invention adds a 3D image acquisition module based on the original TFDS-3 module, and the TFDS-3 module is a dynamic image detection system for truck running faults currently used.

[0018] The TFDS-3 module includes a line-scan camera. The line-scan camera only needs to scan a line when framing the view, so the viewfinder opening can be made very narrow. The influence of external environment such as wind, sand, rain and snow on the equipment is eliminated.

[0019] The TFDS-3 module consists of three parts: trackside equipment, detection station equipment, and train inspection center equipment.

[0020] 1) Railside equipment mainly includes: caisson, side box, junction box, car number antenna, wheel sensor, etc.

[0021] 2) The detection statio...

specific Embodiment approach 2

[0032] The difference between the second embodiment and the first embodiment is that step three is specifically as follows:

[0033] Step 31, using a deep learning model to process the grayscale image, or the 3D image, or the combination of the grayscale image and the 3D image, to identify the type of train;

[0034] Store reference grayscale images of different types of trains, reference 3D images, position marks of train components in the reference grayscale images and in the reference 3D images through a pre-established reference database; and according to the reference grayscale degree image and the reference 3D image training deep learning model for predicting different types of trains;

[0035] The reference grayscale image can be an image collected by a line scan camera and subjected to grayscale and binarization;

[0036] The training of the deep learning model is carried out through a certain number of reference grayscale images and reference 3D images collected in a...

specific Embodiment approach 3

[0044] The difference between the third embodiment and the first or second embodiment is that the 3D image includes a height image and an intensity image, and there is a complete mapping between the height image and the intensity image.

[0045] The image with the pixel gray value of the image of each channel is the intensity image, the intensity image may be a gray image, and the image intensity of the gray image is the pixel gray value.

[0046] The height image of the 3D image has three-dimensional coordinates, the intensity image has a pixel gray value, and each point of the height image corresponds to each point of the intensity image with a pixel gray value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com