Detection device for building materials

A technology for testing devices and building materials, applied in measuring devices, material inspection products, analyzing materials, etc., can solve problems such as different compressive strengths, achieve a reasonable overall concept, ensure complete compliance, and ensure construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

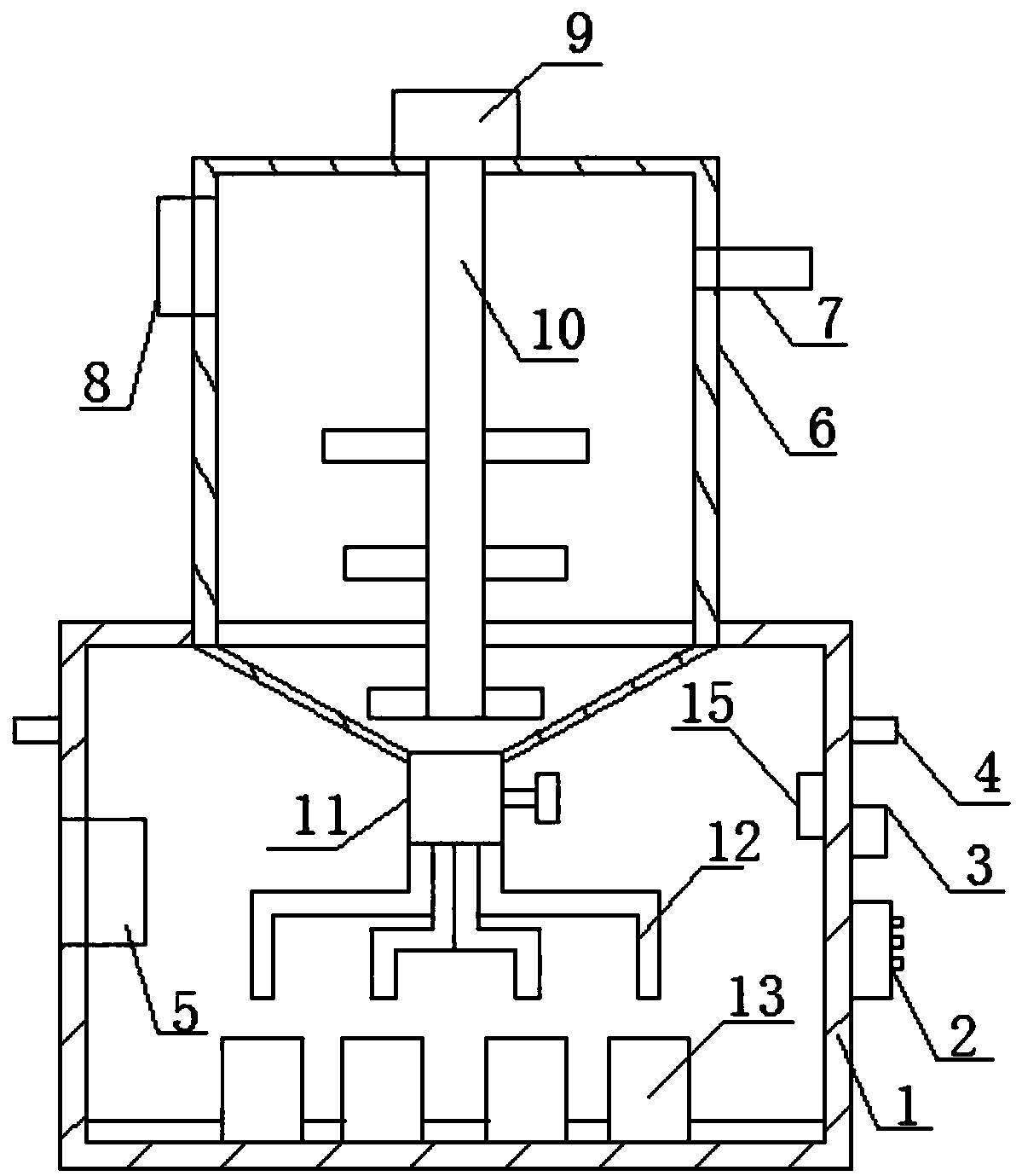

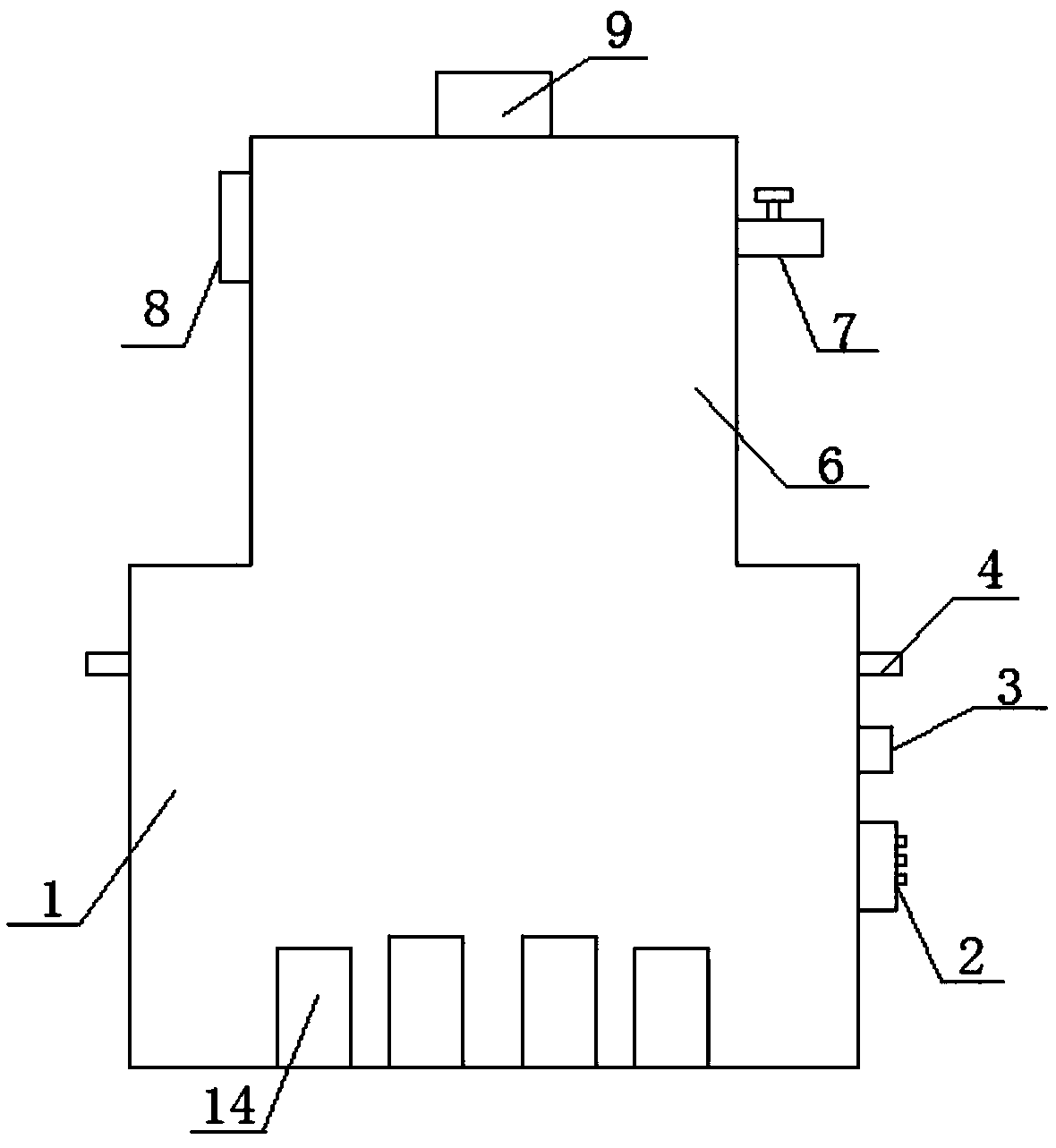

[0020] from Figure 1-2 It can be seen that a building material detection device in this embodiment includes a detection box 1, a control device 2 is arranged on the lower part of the right outer wall of the detection box 1, a timer 3 is installed on the middle part of the right outer wall of the detection box 1, and the detection box 1 A handle 4 is installed on the upper part of the right outer wall of 1, a heater 5 is clamped on the left side wall of the inner cavity of the detection box 1, and a temperature sensor 15 is arranged on the right side wall of the inner cavity of the detection box 1, and the model of the temperature sensor 15 is WZPT -100, the upper end of the detection box 1 is connected with a mixing box 6, the right side wall of the mixing box 6 is provided with a water inlet 7, the left side wall of the mixing box 6 is provided with a feeding port 8, and the top of the mixing box 6 is fixedly installed with a motor 9. Manipulate the control device 2 to turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com