A method for judging no grouting at the measuring point based on the ultrasonic reflection on the surface of the sleeve

An ultrasonic and measuring point technology, which is applied in the analysis of fluids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. Achieve the effect of low cost, fast detection speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

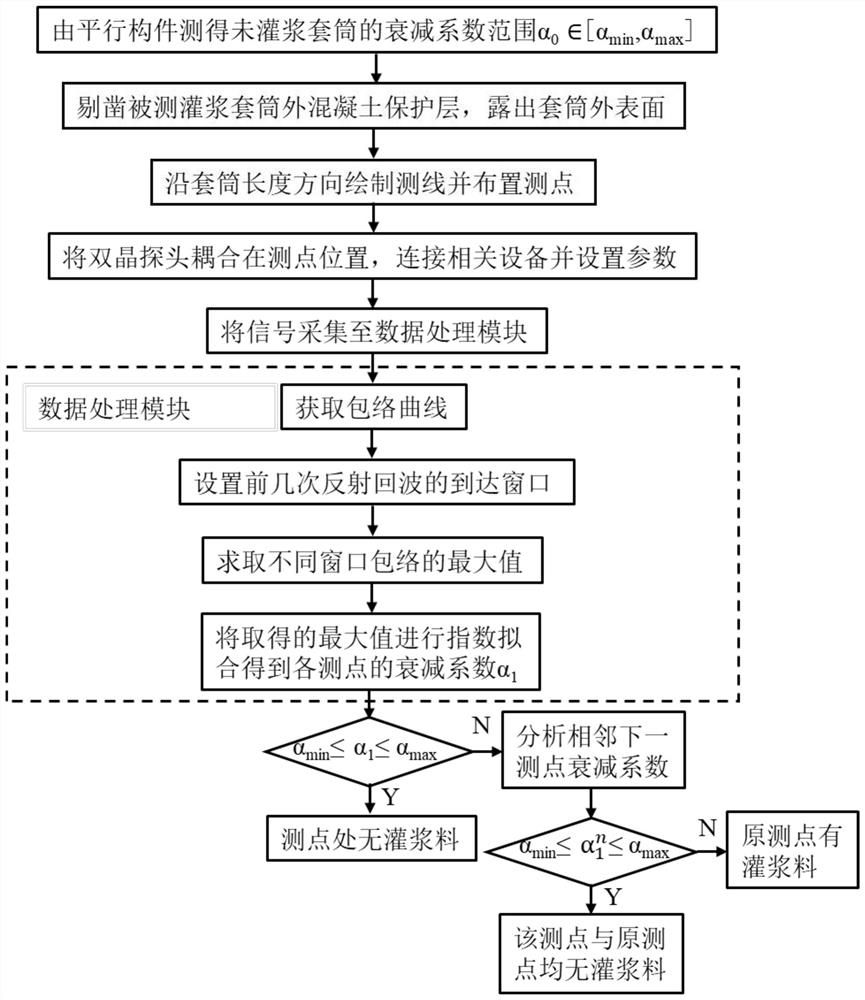

[0044] An embodiment of the method of judging no grouting at the measuring point based on the ultrasonic reflection on the surface of the sleeve of the present invention:

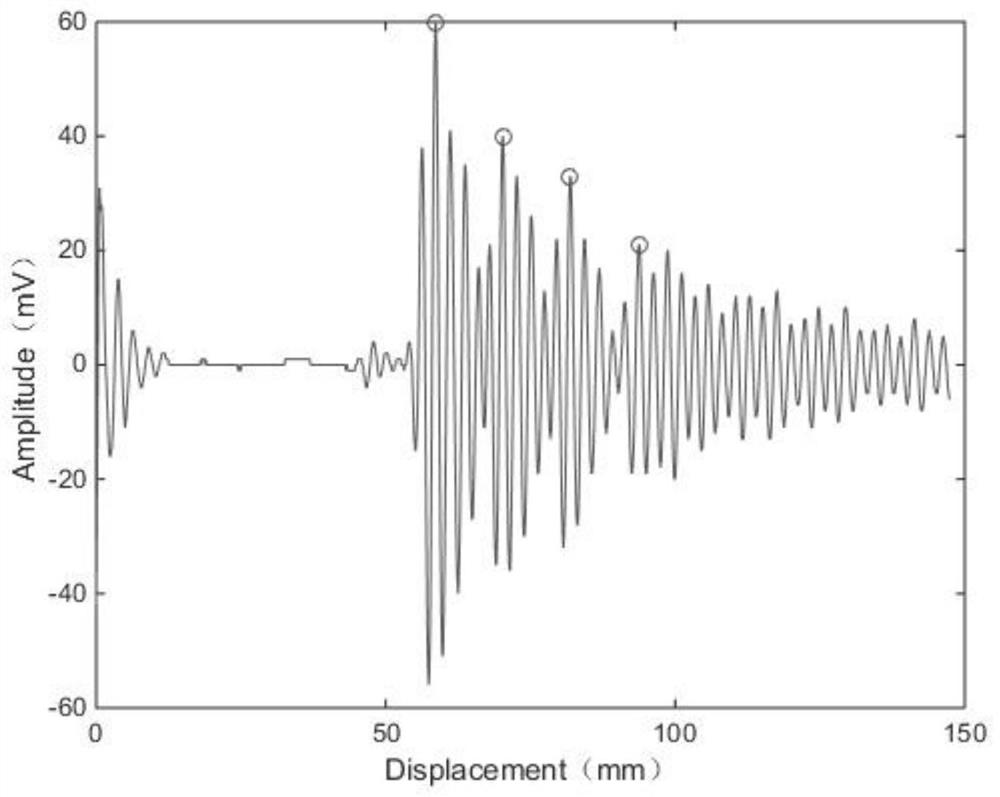

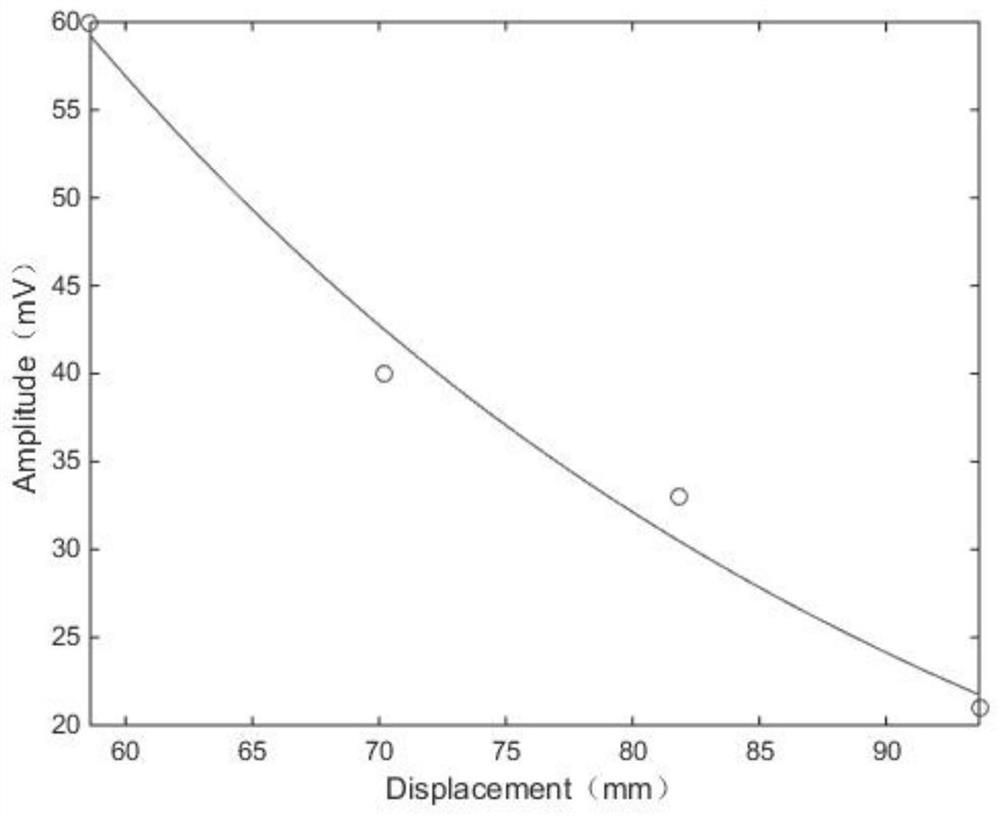

[0045] The phenomenon of reflection and transmission will occur when the ultrasonic wave passes through different media during the propagation process. When the ultrasonic wave passes through the inner wall of the sleeve and the air interface, due to the large difference in the acoustic impedance of the two media, the reflected wave is relatively strong. In actual operation The signal obtained in the medium is stronger, which is convenient to obtain the characteristic signal and perform data processing; when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com