A kind of X-ray layered multilayer film grating structure with inclined side wall

A grating structure and multi-layer film technology, applied in radiation/particle processing, using aperture/collimator, applying diffraction/refraction/reflection for processing, etc., can solve collapse damage, affect optical performance, poor mechanical stability, etc. problem, to achieve the effect of suppressing vibration, improving spectral purity and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and a detailed implementation mode and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

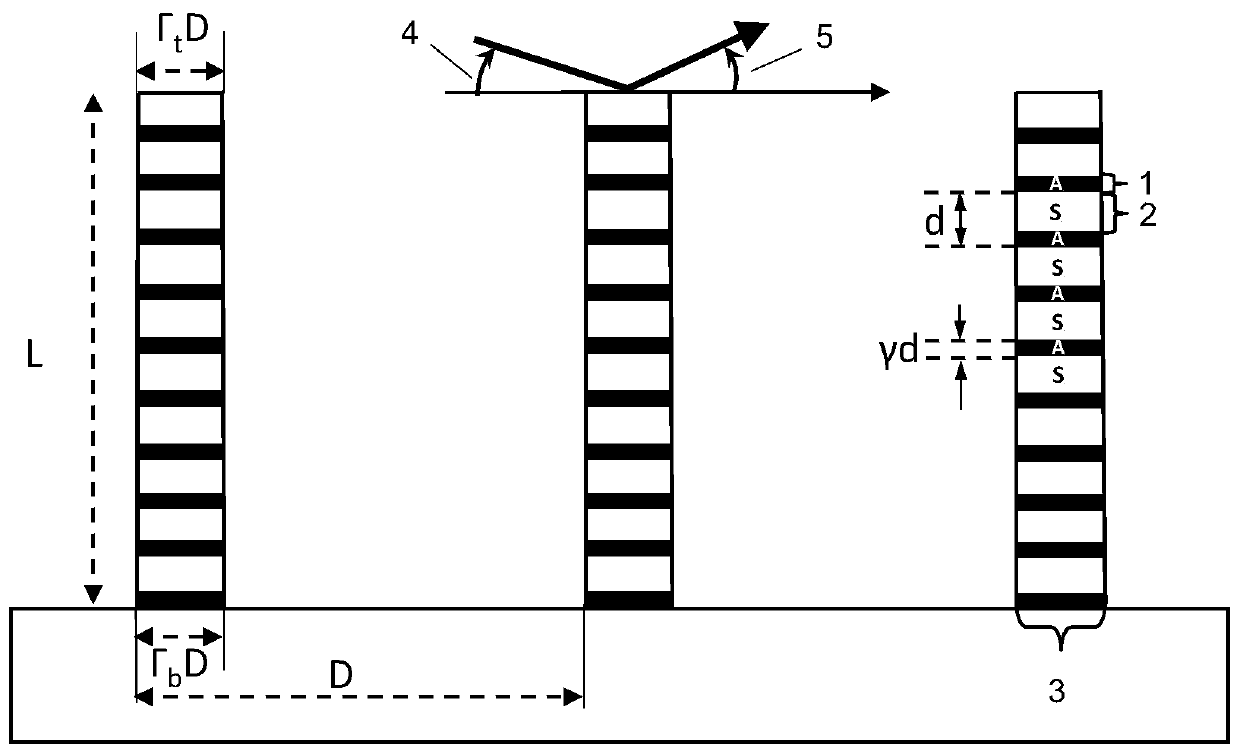

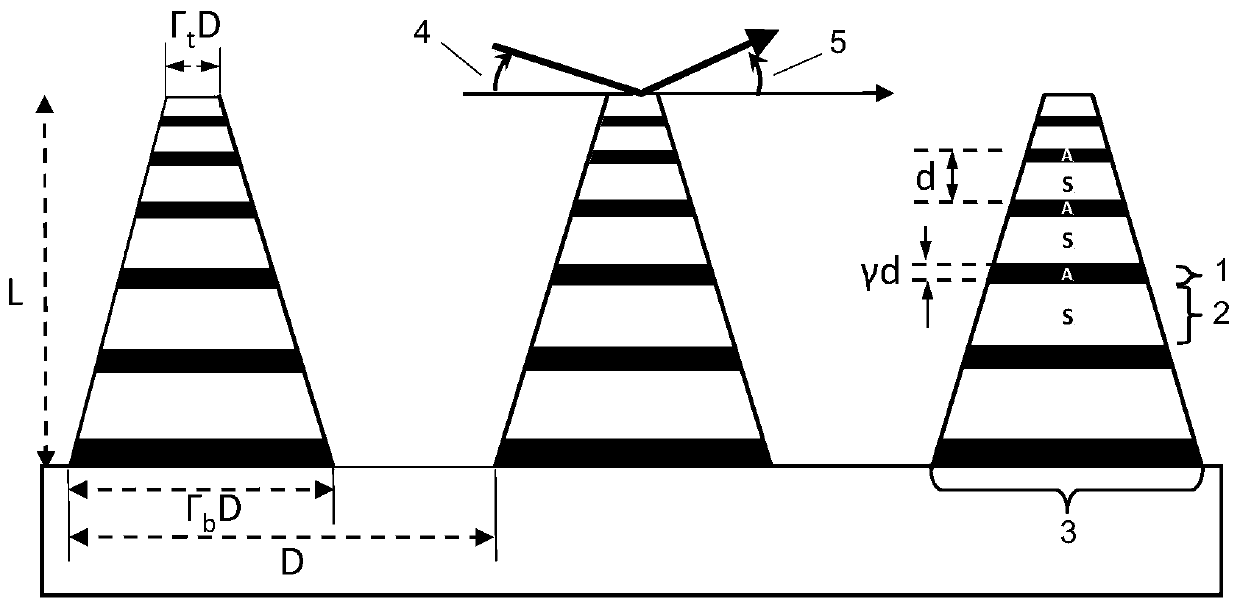

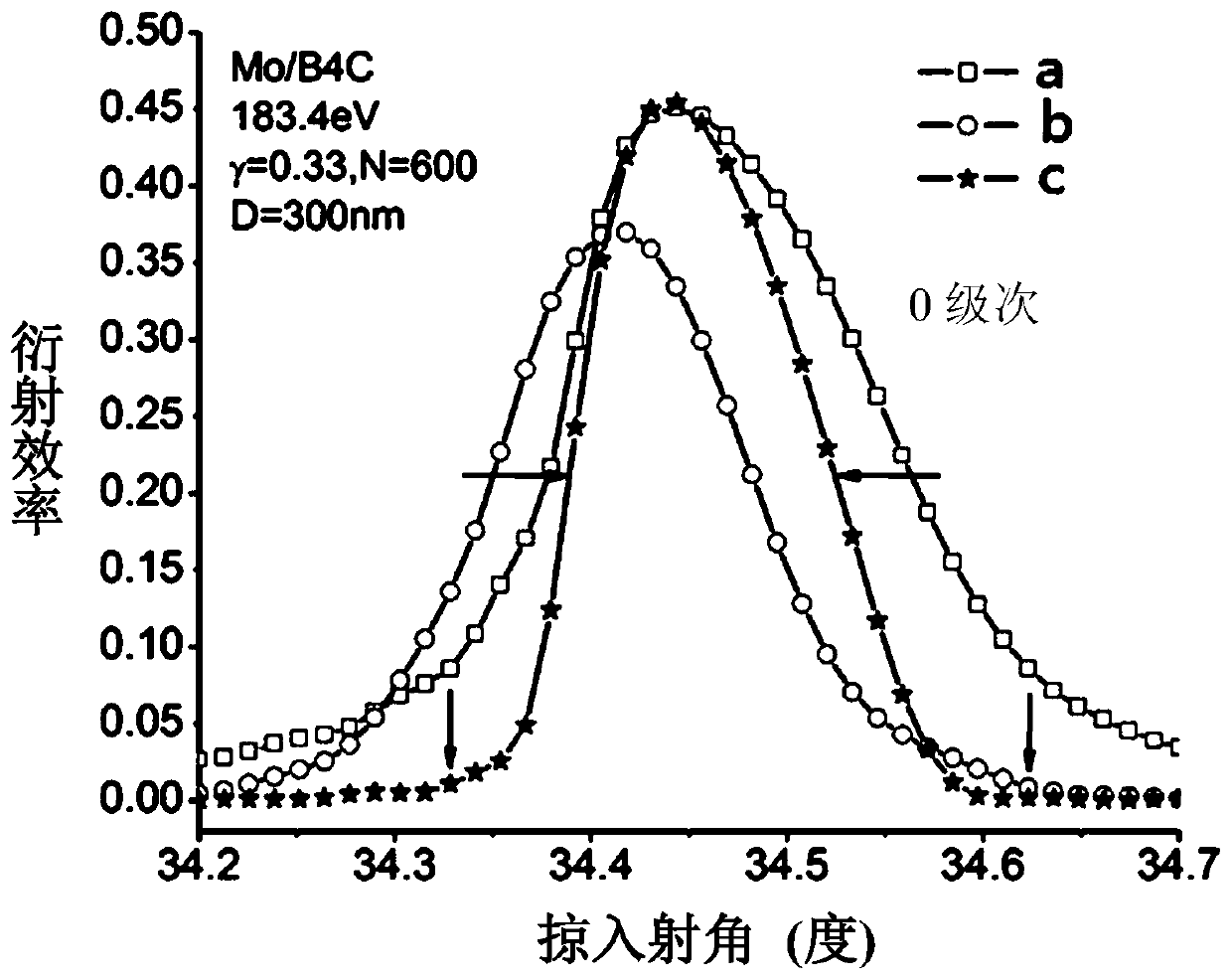

[0034] The embodiment of the present invention provides a Tilted Lamellar Multilayer Gratings (TLMG) with inclined sidewalls, which is suitable for use as a high-efficiency and high-resolution spectroscopic monochromator in X-ray spectroscopy experiments. Such as figure 2 As shown, the grating structure includes periodic multilayer film stacks 3, the formed grating period is D, the center position of the multilayer film stack 3 coincides with the center position of each grating period, and the multi-layer film stack 3 has a duty ratio from the top It increases monotonously to the bottom, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com