Brushless DC motor

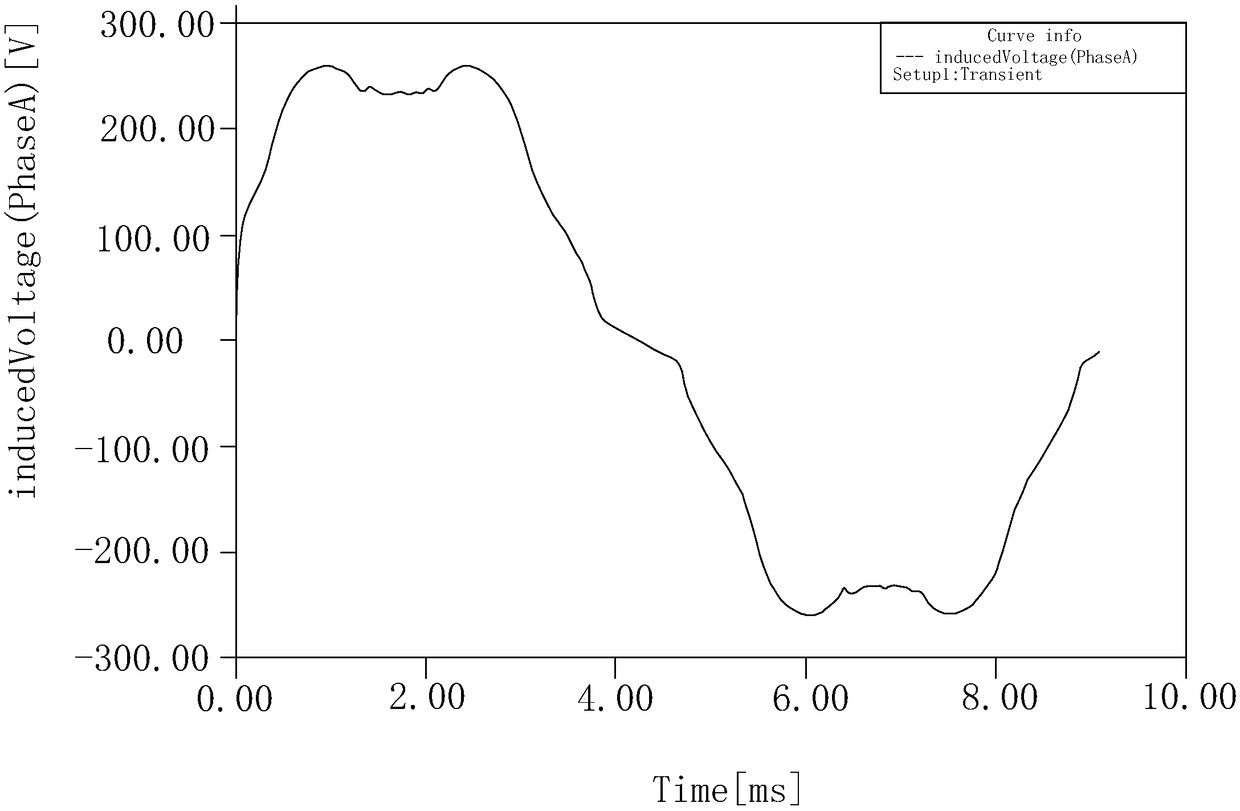

A brushless DC motor and rotor technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of large difference in sine wave waveform, large motor vibration, and many back-EMF harmonics, and achieve small back-EMF harmonics. , not easy to move, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

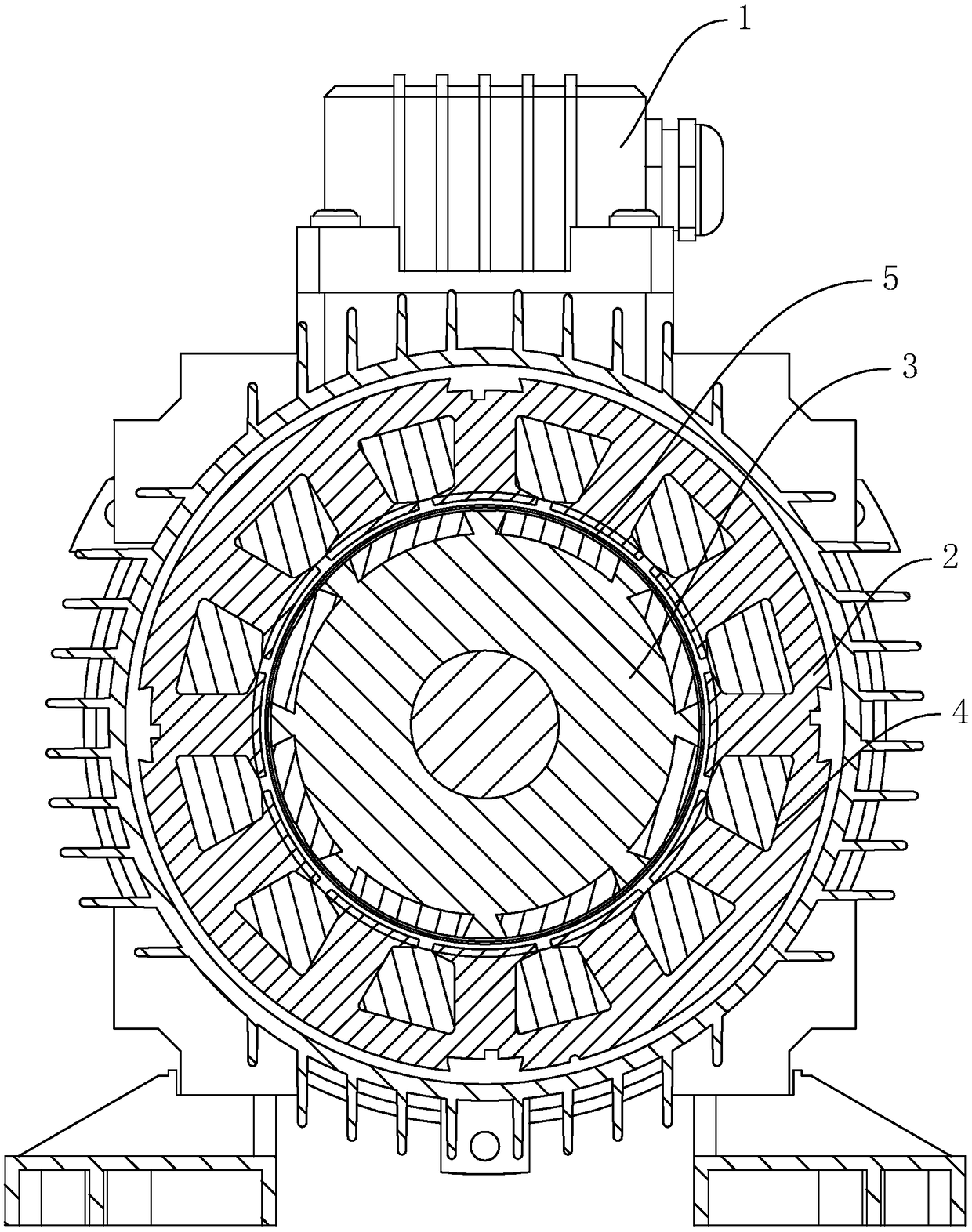

[0034] A DC brushless motor such as Figure 4 , Figure 5 As shown, it includes a housing 1 , a stator 2 coaxially embedded in the housing 1 , and a rotor 3 coaxially connected to the housing 1 for rotation.

[0035] Such as Figure 5 As shown, in this embodiment, the diameter of the outer ring of the stator 2 is 130 mm, and the diameter of the inner ring of the stator 2 is 84 mm. The inner wall of the stator 2 close to the rotor 3 is provided with 12 winding slots 4 , and the 12 winding slots 4 are evenly distributed around the axis of the stator 2 . Each winding slot 4 extends axially along the stator 2 , and two ends of the winding slot 4 pass through the two ends of the stator 2 respectively. Each winding slot 4 shrinks toward one side of the stator 2 axis. In this embodiment, the depth of the winding groove 4 is 14.5mm. The inner slot walls of the winding slot 4 are rounded, and the radius of the rounded corners is 1mm. An abutment block 7 is integrally formed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com