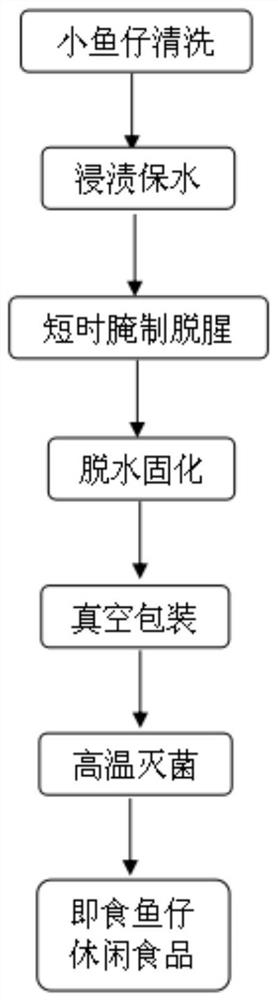

A method for improving texture of ready-to-eat fish larvae

A kind of fish larvae and texture technology, which is applied in the fields of food ingredients containing natural extracts, food science, food ingredients, etc., can solve the problems of lack of chewy taste, incompleteness, and fine fiber structure, so as to shorten the cooking time and satisfy the food requirements. Nutrition, the effect of reducing the deterioration of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of impregnating solution: parts by mass ratio, taking phosphate (pyrophosphate) an amount of 2 parts After 100 parts of purified water was stirred to obtain steep liquor, spare.

[0036] (2) the pickling liquid formulation: 0.5 parts take fennel, 0.2 parts of pepper, 0.5 parts of anise, 1.2 parts of onion, 0.8 parts of ginger mixed, wrapped with gauze made pickled material package, then the package material is placed 100 parts water boiled 10min, the package material is removed to obtain a pickling liquid.

[0037] (3) seasoning liquid formulation: parts by mass basis, taking 20 parts soybean oil, 5 parts of dried chili, 8 parts of bean paste, mixed frying to give chili oil, spare; mass fraction of the total, taking the content of said agar 1 parts of monosodium glutamate 1 part, 2 parts sugar, 0.5 parts of pepper, 0.5 parts of garlic powder, 0.5 parts of ginger mixed, wrapped with gauze made pickled material package, then the package material is placed 100 ...

Embodiment 2

[0047] (1) Preparation of impregnating solution: parts by mass ratio, taking phosphates (sodium tripolyphosphate) an amount of 2 parts, transglutaminase (124U / g) 1 parts After 100 parts of purified water was stirred to give impregnating solution, standby.

[0048] (2) the pickling liquid formulation: 0.5 parts take fennel, 0.2 parts of pepper, 0.5 parts of anise, 1.2 parts of onion, 0.8 parts of ginger mixed, wrapped with gauze made pickled material package, then the package material is placed 100 parts water boiled 10min, the package material is removed to obtain a pickling liquid.

[0049] (3) seasoning liquid formulation: parts by mass basis, taking 20 parts soybean oil, 5 parts of dried chili, 8 parts of bean paste, mixed frying to give chili oil, spare; mass fraction of the total, taking the content of said agar 1 parts of monosodium glutamate 1 part, 2 parts sugar, 0.5 parts of pepper, 0.5 parts of garlic powder, 0.5 parts of ginger mixed, wrapped with gauze made pickled m...

Embodiment 3

[0059] (1) Preparation of impregnating solution: parts by mass ratio, the phosphate content takes (sodium tripolyphosphate) 4 parts, transglutaminase (124U / g) 3 parts After 100 parts of purified water was stirred to give impregnating solution, standby.

[0060] (2) Preparation of curing solution: Take 1 part of fennel, 0.8 parts of pepper, aniseed parts 1, 1.6 parts of onion, 1.4 parts of ginger mixed, wrapped with gauze made pickled material package, then the package material is placed 100 parts after the boiling water 20min, the package material is removed to obtain a pickling liquid.

[0061] (3) seasoning liquid formulation: parts by mass basis, taking 30 parts of soybean oil, chili parts 6, 9 parts of bean paste, mixed frying to give chili oil, spare; mass fraction of the total, taking the content of said agar 3 parts, MSG 3 parts, 4 parts of sugar, 1.5 parts of pepper, 1.5 parts of garlic powder, ginger powder mixing 1.5 parts, wrapped with gauze made pickled material pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com