Blade drilling device for electric fan

A drilling device and electric fan technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., can solve the problem of low efficiency of coolant use and achieve improved cooling efficiency and circulation The effect of high efficiency and increased volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

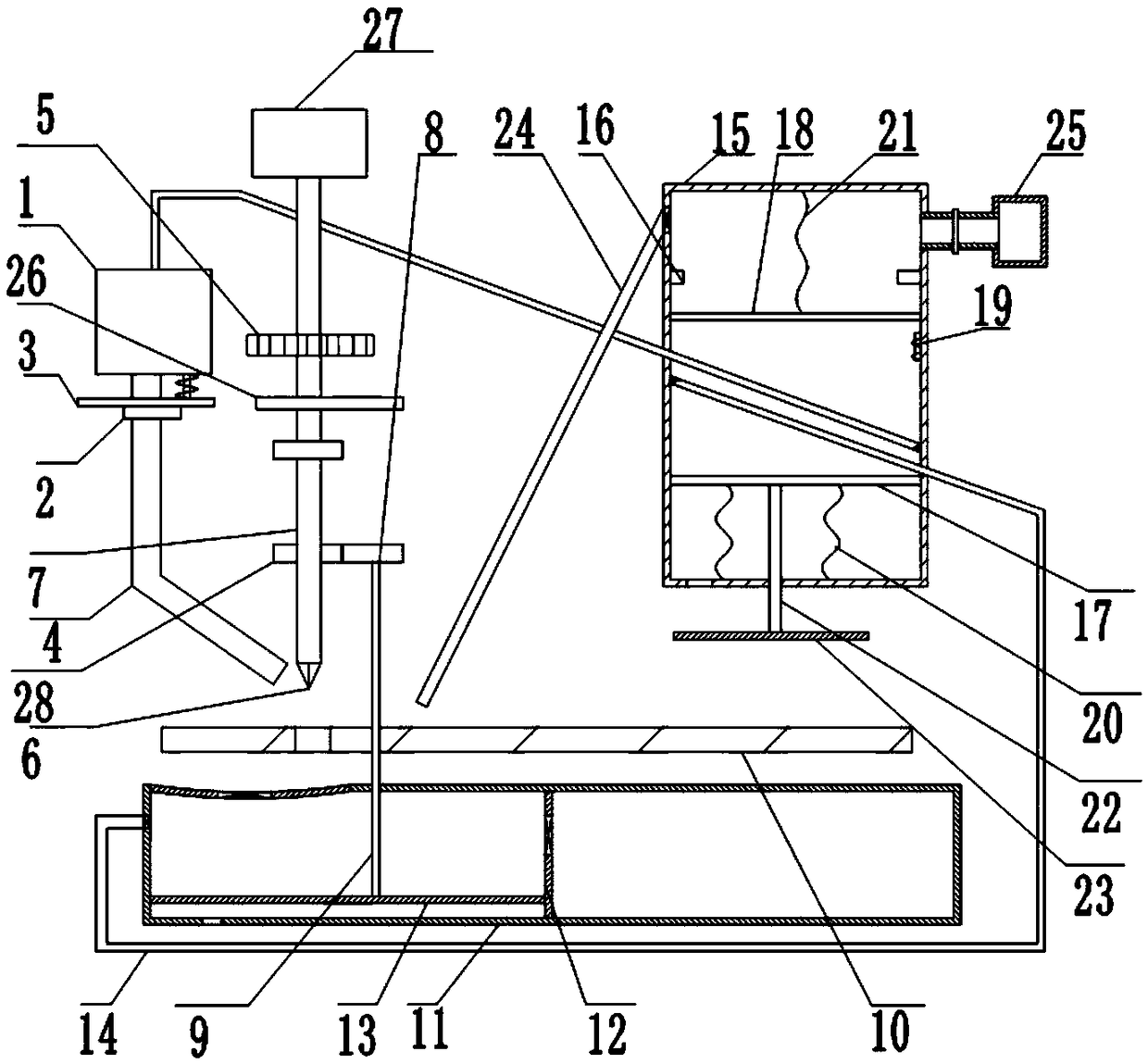

[0025] A blade drilling device for an electric fan, such as figure 1 As shown, including the frame, the cooling box 1, the workbench 10 and the workbox 11 are fixed sequentially on the frame from top to bottom. The ratio of the cross-sectional area of the upper surface of the workbox 11 to the workbench 10 is 5:3. The edge profile of the upper surface of the table 10 is wedge-shaped, and the top of the workbench 10 is provided with a drilling device fixed on the frame. The workbench is provided with a through hole positioned directly below the drilling device. Drill bit 6 and threaded rod 7, cylinder 27, motor 5, threaded rod 7 and drill bit 6 are arranged on the frame successively from top to bottom. The bottom of the cooling box 1 is connected with a liquid outlet pipe 4 with the nozzle facing the drill bit 6. The liquid outlet pipe 4 is coaxially connected with a rotary valve 2, and the rotary valve 2 is coaxially connected with a ring gear 3. The top of the rotary valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com