An environmentally friendly plywood pressing device

A pressing device and technology for plywood, applied in the direction of plywood presses, veneer presses, manufacturing tools, etc., can solve the problems of affecting the quality of finished products, uneven pressing force of plywood, weak force, etc., to avoid the size of the thrust Different, improve the effect, avoid the effect of excessive concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

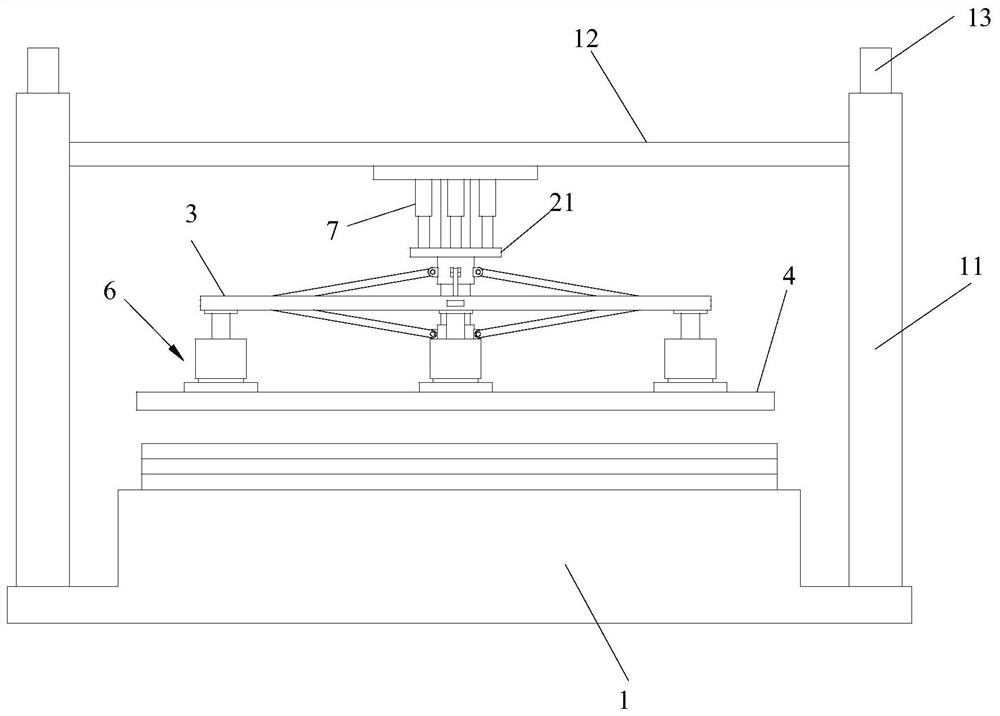

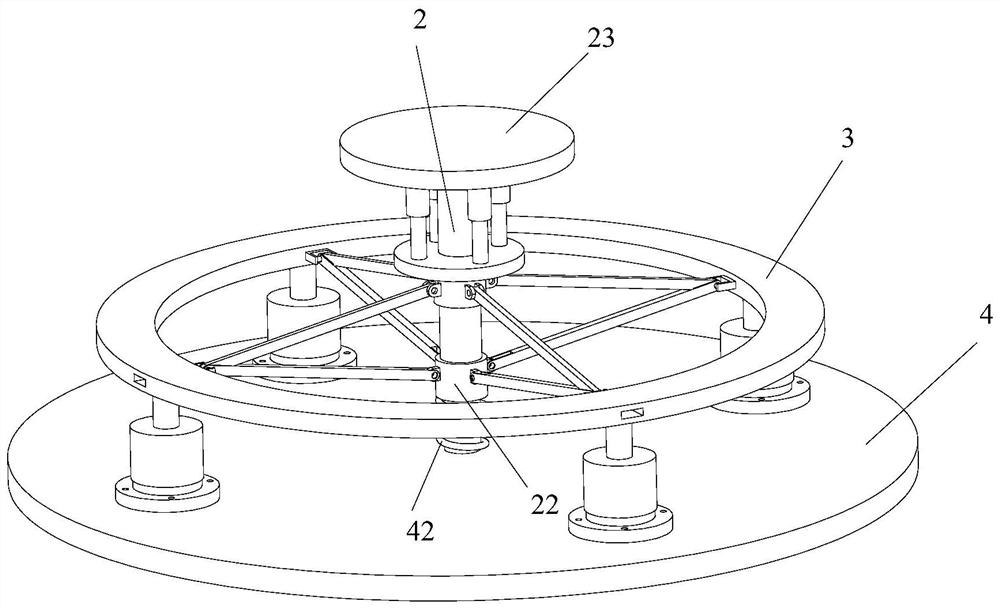

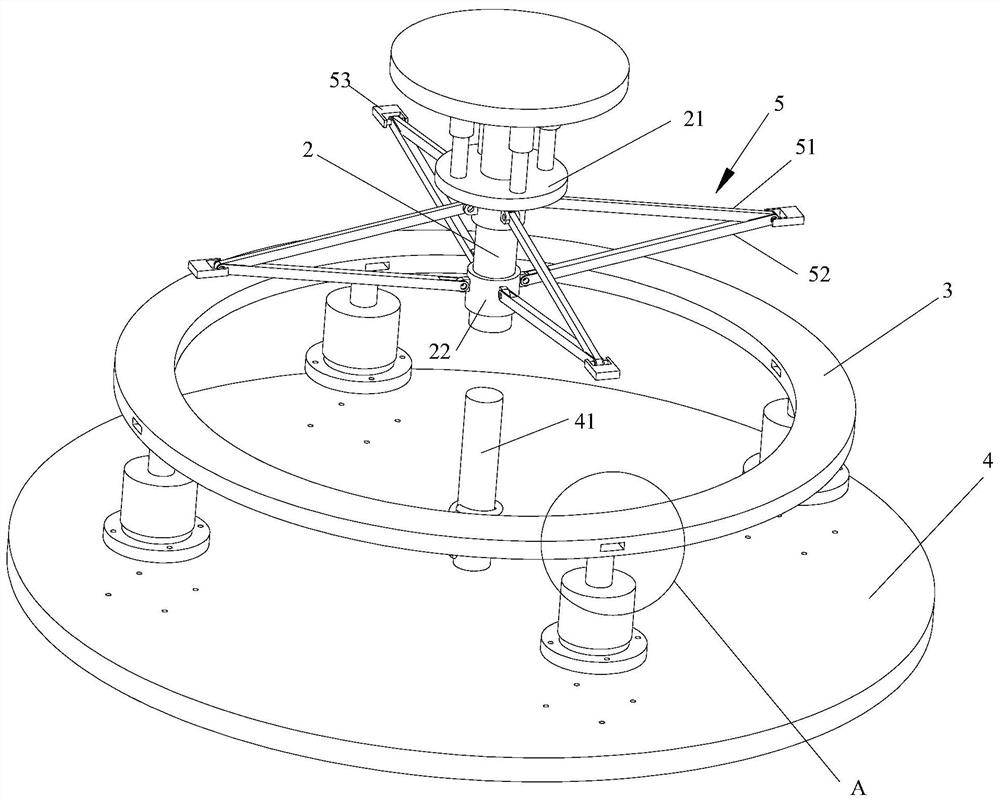

[0025] Embodiment 1: An environment-friendly plywood pressing device, comprising a base 1 and two lifting columns 11 symmetrically arranged on the base 1, a beam 12 capable of moving up and down is arranged between the two lifting columns 11, The crossbeam 12 moves up and down through the lead screw arranged in the lifting column 11, the two ends of the crossbeam 12 are threadedly assembled with the lead screw respectively, and the top of the lifting column 11 is fixedly provided with a lifting motor for driving the lead screw to rotate. 13, wherein the lifting motor 13 is a stepping motor or a servo motor with a self-locking function, the middle part of the beam 12 is fixed with a main shaft 2 through a fixed plate 23, and the main shaft 2 is nested with a driving flange from top to bottom 21 and a support sleeve 22, four push cylinders 7 evenly distributed along the circumferential direction are arranged between the driving flange 21 and the fixed plate 23, and the pressure p...

Embodiment 2

[0032] Embodiment 2: On the basis of Embodiment 1, the elastic member (disc spring 64) of the pushing unit 6 can also be replaced by a second cylindrical spring. In this embodiment, the compression displacement of the pushing unit 6 The amount greater than the compression displacement of the first cylindrical spring 42 means that under the same force, the compression amount of the second cylindrical spring is greater than the compression amount of the first cylindrical spring 42, that is, when the driving flange 21 presses down and applies force. During the process, both the first cylindrical spring 42 and the second cylindrical spring are deformed at first, and then the first cylindrical spring 42 remains undeformed, and the second cylindrical spring continues to deform.

[0033] In other embodiments, the number of the pushing cylinder 7 , the link mechanism 5 and the pushing unit 6 can be further increased according to the size of the actually processed plywood, so as to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com