A treatment method for improving the surface printing performance of corrugated cartons

A corrugated box, surface printing technology, applied in the field of processing to improve the surface printing performance of corrugated boxes, to achieve long life, good use stability, and improve the effect of surface printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

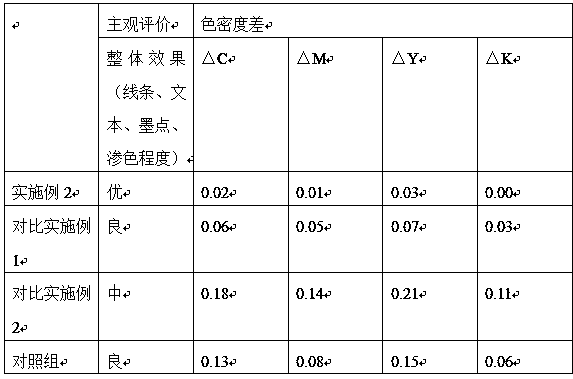

Examples

Embodiment 1

[0032] A treatment method for improving the printing performance on the surface of a corrugated box, comprising compounding a layer of modified reinforcement film on the surface of the corrugated box, specifically comprising the following steps:

[0033] (1) Preparation of reinforcing filler:

[0034] a. First add ethanol solution to the reactor, then add divinylbenzene, hydroxyethyl methacrylate, and stabilizer to the reactor, and then continuously stir at a speed of 400 rpm for 1 hour;

[0035] b. Then add nano-silver particles and disodium ethylenediaminetetraacetate to the reactor after operation a, and then ultrasonically treat for 2 hours;

[0036] c. Then add the initiator to the reaction kettle after operation b, heat to keep the temperature in the reaction kettle at 74°C, and increase the pressure in the reaction kettle to 0.23MPa at the same time. The kettle was discharged to normal pressure, and the temperature in the reaction kettle was raised to 82°C, and the hea...

Embodiment 2

[0052] A treatment method for improving the printing performance on the surface of a corrugated box, comprising compounding a layer of modified reinforcement film on the surface of the corrugated box, specifically comprising the following steps:

[0053] (1) Preparation of reinforcing filler:

[0054] a. First add ethanol solution into the reactor, then add divinylbenzene, hydroxyethyl methacrylate, and stabilizer into the reactor, and then continuously stir at a speed of 420 rpm for 1.3 hours;

[0055] b. Then add nano-silver particles and disodium ethylenediaminetetraacetate into the reactor after operation a, and then ultrasonically treat for 2.2 hours;

[0056] c. Then add the initiator to the reactor after operation b, heat to keep the temperature in the reactor at 76°C, and increase the pressure in the reactor to 0.25MPa at the same time. The kettle was discharged to normal pressure, and the temperature in the reactor was raised to 84°C, and the heat preservation treatm...

Embodiment 3

[0072] A treatment method for improving the printing performance on the surface of a corrugated box, comprising compounding a layer of modified reinforcement film on the surface of the corrugated box, specifically comprising the following steps:

[0073] (1) Preparation of reinforcing filler:

[0074] a. First add ethanol solution into the reactor, then add divinylbenzene, hydroxyethyl methacrylate, and stabilizer into the reactor, and then continuously stir at a speed of 440 rpm for 1.5 hours;

[0075] b. Then add nano-silver particles and disodium ethylenediaminetetraacetate into the reactor after operation a, and then ultrasonically treat for 2.5 hours;

[0076] c. Then add the initiator to the reaction kettle after operation b, heat to keep the temperature in the reaction kettle at 78°C, and increase the pressure in the reaction kettle to 0.26MPa at the same time. Unload to normal pressure, and raise the temperature in the reactor to 85°C, and continue the heat preservati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com