PVC composite insulating material, electric wire and its preparation method and application

A composite insulation and wire technology, applied in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as poor heat resistance and thermal aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

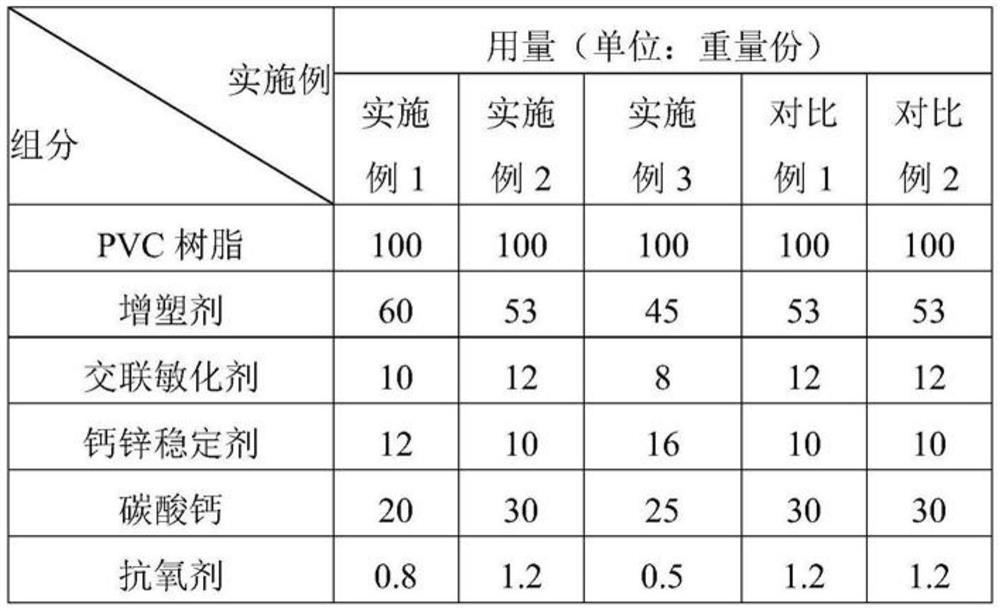

[0041]The consumption of each component in embodiment 1 is as shown in table 1. Among them, the degree of polymerization of the PVC resin is 1800, the plasticizer is TINTM, the crosslinking sensitizer is TMPTA, the calcium zinc stabilizer is Bear brand BP MC 8890KA, and the antioxidant is 1010.

[0042] 1. Preparation of PVC composite insulation material:

[0043] After mixing the plasticizer and the cross-linking sensitizer uniformly for 15 minutes, the mixture A was obtained, and then kept stirring for later use; after mixing the PVC resin and the mixture A uniformly for 1 minute, and then adding the remaining raw materials for 4 minutes, the mixture was obtained;

[0044] Put the mixture directly into the twin-screw compounder for extrusion and granulation. Wherein, the equipment adopted during extrusion granulation is a conventional twin-screw feeder in the field; in the twin-screw feeder, the diameter of the screw is 75 mm, and the length-to-diameter ratio is 40:1; the s...

Embodiment 2

[0049] The consumption of each component in embodiment 2 is as shown in table 1. Among them, the degree of polymerization of the PVC resin is 2500, the plasticizer is triisodecyl trimellitate, the crosslinking sensitizer is TMPTMA, the calcium zinc stabilizer is Bear brand BP MC 8890KA, and the antioxidant is 1076. 1, the preparation of PVC composite insulating material:

[0050] Mix the plasticizer and the cross-linking sensitizer uniformly for 10 minutes to obtain the mixture A, and then keep stirring for future use; mix the PVC resin and the mixture A uniformly for 1 minute, and then add the remaining raw materials for 8 minutes to obtain the mixture;

[0051] Just put the mixture directly into the twin-screw compounder for extrusion and compounding. Wherein, the equipment adopted during extrusion granulation is a conventional twin-screw feeder in the field; in the twin-screw feeder, the diameter of the screw is 75 mm, and the length-to-diameter ratio is 40:1; the speed of...

Embodiment 3

[0056] The consumption of each component in embodiment 3 is as shown in table 1. Wherein, the polymerization degree of PVC resin is 2500, and plasticizer is trimellitate tri(n-octyldecyl) ester, and crosslinking sensitizer is TMPTA, and calcium zinc stabilizer is Bear brand BP MC 8890KA, and antioxidant is 1076.

[0057] 1. Preparation of PVC composite insulation material:

[0058] Mix the plasticizer and cross-linking sensitizer uniformly for 18 minutes to obtain mixture A, and keep stirring thereafter for future use; mix the PVC resin and mixture A uniformly for 1 minute, and then add the remaining raw materials for 6 minutes to obtain the mixture;

[0059] Just put the mixture directly into the twin-screw compounder for extrusion and compounding. Wherein, the equipment adopted during extrusion granulation is a conventional twin-screw feeder in the field; in the twin-screw feeder, the diameter of the screw is 75 mm, and the length-to-diameter ratio is 40:1; the speed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com