Polypropylene printing film preparation method of high-strength abrasion resistant flower

A polypropylene, high-strength technology, applied in the field of high-strength anti-friction polypropylene printing film preparation, can solve the problems of weak water vapor barrier, low quality, easy to scratch, etc., achieve excellent mechanical strength, increase dosage, improve Effect of Surface Printability and Scratch Resistance of Printed Layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] The application principle of the present invention will be further described below in conjunction with the accompanying drawings.

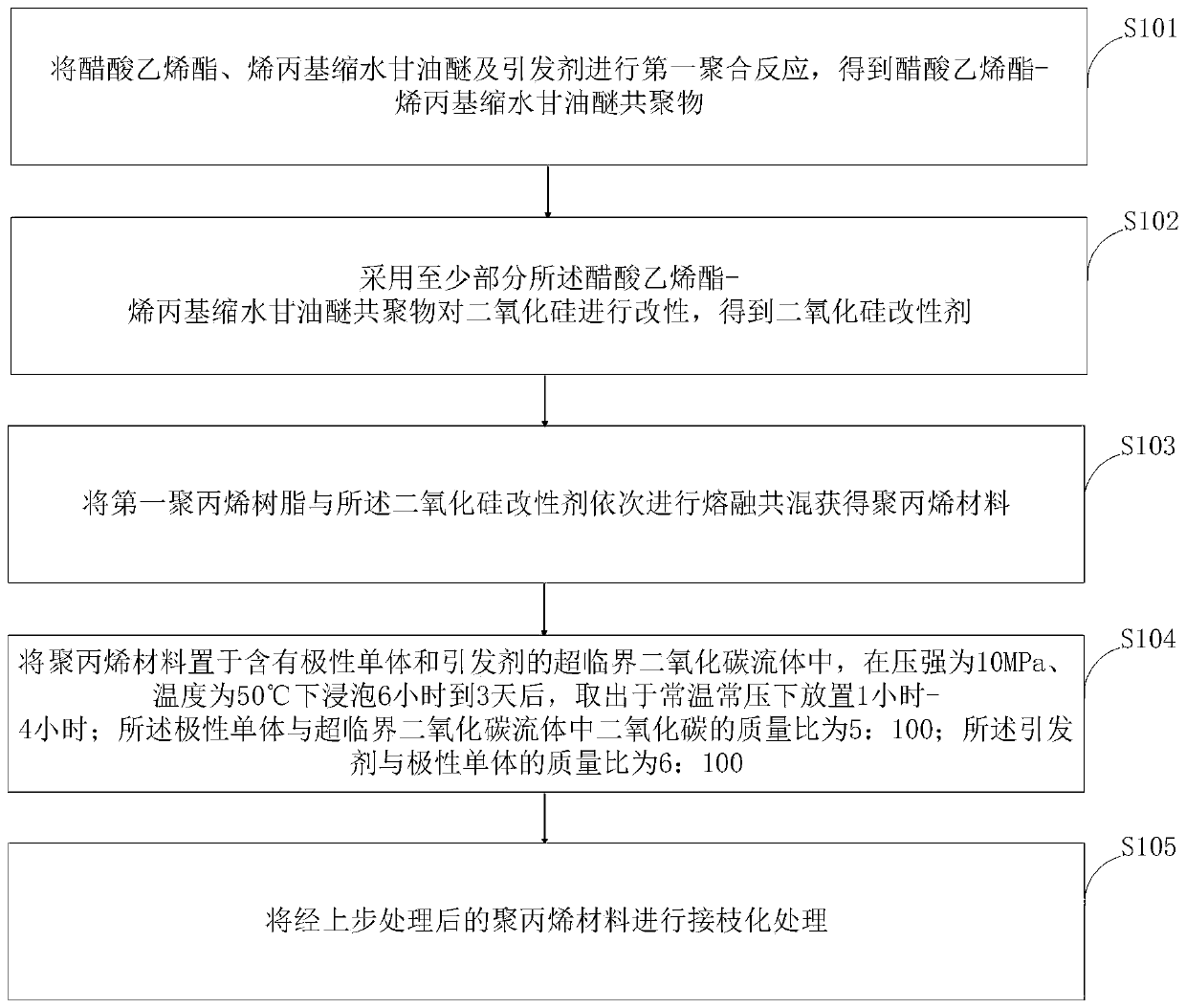

[0023] Such as figure 1 As shown, the present invention provides a kind of high-strength anti-friction polypropylene printing film preparation method comprising the following steps:

[0024] Step S101, performing a first polymerization reaction on vinyl acetate, allyl glycidyl ether and an initiator to obtain a vinyl acetate-allyl glycidyl ether copolymer;

[0025] Step S102, using at least part of the vinyl acetate-allyl glycidyl ether copolymer to modify silica to obtain a silica mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com