A waterproof and folding-resistant hang tag and its manufacturing process

A production process and folding-resistant technology, applied in the field of rubber and plastic products, can solve the problems of poor surface printing performance, not durable, and high tag density, achieve broad market application prospects, improve quality stability, and good surface printing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

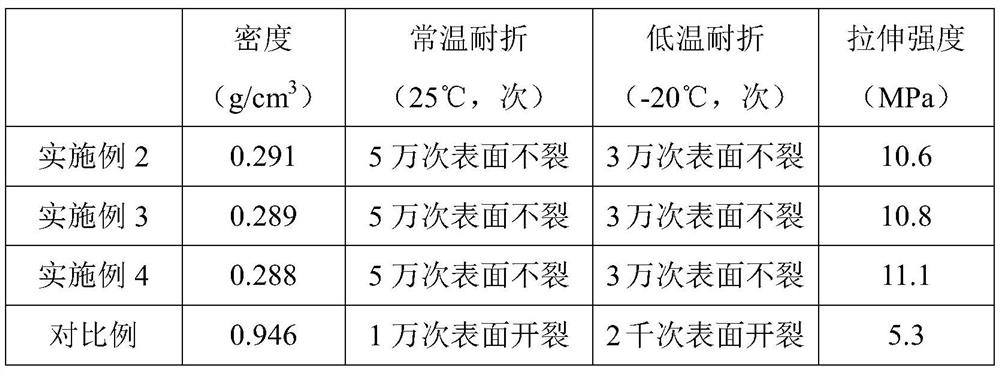

Examples

Embodiment 1

[0041] A waterproof and foldable hang tag, made of the following raw materials by weight:

[0042]200-250 parts of ethylene-vinyl acetate copolymer, 140-168 parts of nitrile rubber, 115-130 parts of polyester-polyether multi-block copolymer, polystyrene-poly(ethylene-butylene)-polystyrene block 45-53 parts of segment copolymer, 30-37 parts of branched polybutylene succinate copolymer, 25-30 parts of polyethyleneimine, 20-25 parts of glass fiber, 15-18 parts of nano-silica, 6-9 parts of foaming agent, 3-4 parts of zinc isooctanoate, 9-12 parts of processing aid, 4-6 parts of bridging agent, 10-15 parts of antioxidant, and 10-15 parts of heat stabilizer.

[0043] Preferably, the waterproof and foldable hang tag is made of the following raw materials in parts by weight: 225 parts of ethylene-vinyl acetate copolymer, 152 parts of nitrile rubber, 123 parts of polyester-polyether multi-block copolymer, polystyrene - 49 parts of poly(ethylene-butylene)-polystyrene block copolymer, 3...

Embodiment 2

[0057] A waterproof and foldable hang tag, made of the following raw materials by weight:

[0058] 200 parts of ethylene-vinyl acetate copolymer, 140 parts of nitrile rubber, 115 parts of polyester-polyether multi-block copolymer, 45 parts of polystyrene-poly(ethylene-butylene)-polystyrene block copolymer, 30 parts of branched polybutylene succinate copolymer, 25 parts of polyethyleneimine, 20 parts of glass fiber, 15 parts of nano silicon dioxide, 6 parts of foaming agent, 3 parts of zinc isooctanoate, 9 parts of processing aid 4 parts, 4 parts of bridging agent, 10 parts of antioxidant, 10 parts of heat stabilizer.

[0059] In this embodiment, the processing aid is a mixture of oxidized polyethylene and maleic anhydride grafted polyethylene.

[0060] In this embodiment, the mass ratio of the oxidized polyethylene and the maleic anhydride-grafted polyethylene in the mixture of the oxidized polyethylene and the maleic anhydride-grafted polyethylene is 10:16.

[0061] In this...

Embodiment 3

[0072] A waterproof and foldable hang tag, made of the following raw materials by weight:

[0073] 250 parts of ethylene-vinyl acetate copolymer, 168 parts of nitrile rubber, 130 parts of polyester-polyether multi-block copolymer, 53 parts of polystyrene-poly(ethylene-butylene)-polystyrene block copolymer, 37 parts of branched polybutylene succinate copolymer, 30 parts of polyethyleneimine, 25 parts of glass fiber, 18 parts of nano silicon dioxide, 9 parts of foaming agent, 4 parts of zinc isooctanoate, 12 parts of processing aid 6 parts, 6 parts of bridging agent, 15 parts of antioxidant, 15 parts of heat stabilizer.

[0074] In this embodiment, the processing aid is a mixture of oxidized polyethylene and maleic anhydride grafted polyethylene.

[0075] In this embodiment, the mass ratio of the oxidized polyethylene and the maleic anhydride-grafted polyethylene in the mixture of the oxidized polyethylene and the maleic anhydride-grafted polyethylene is 10:19.

[0076] In thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com