Traffic sign on luminescent road and lamp bead lens for traffic sign

A technology for road traffic and light-emitting lights, applied in road signs, roads, roads and other directions, can solve the problems of cumbersome installation methods, rising production and installation costs, low work efficiency, etc., to reduce processing costs, reduce processing accuracy requirements, reduce The effect of making installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

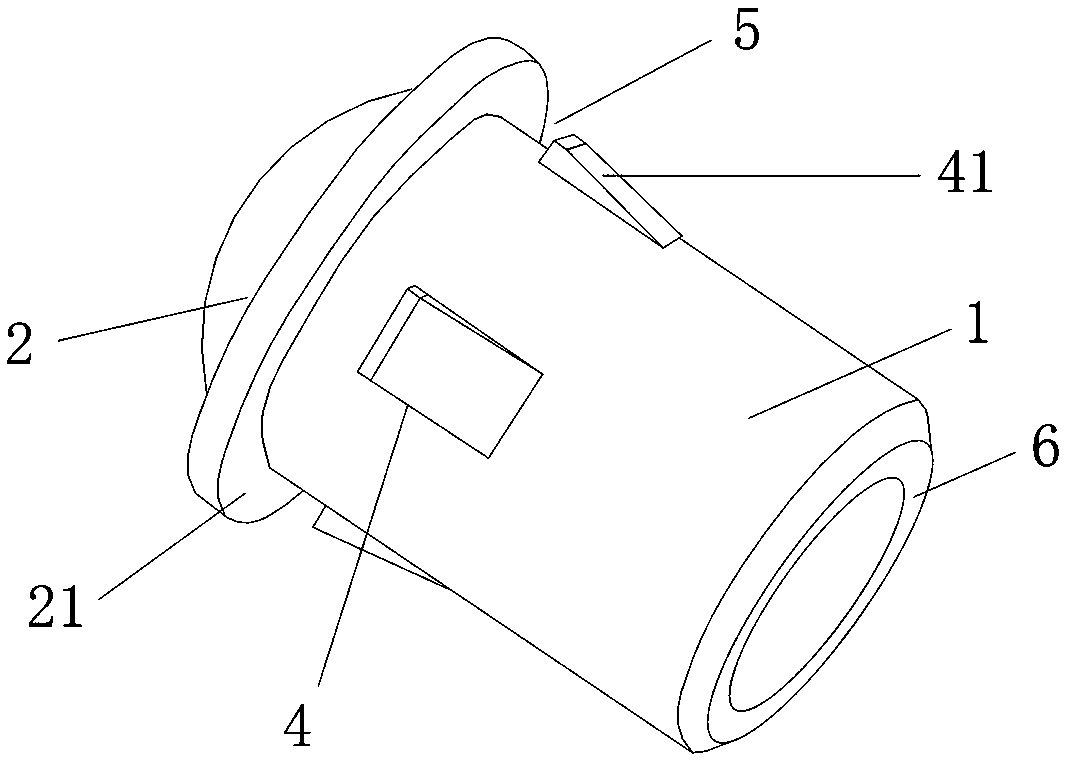

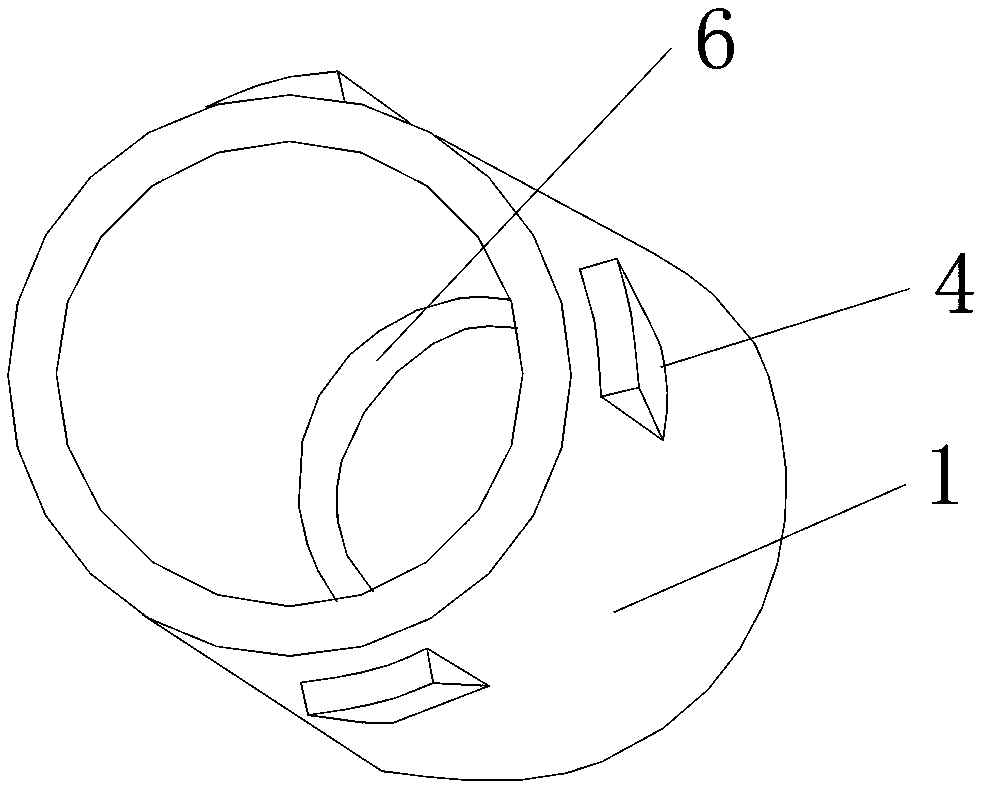

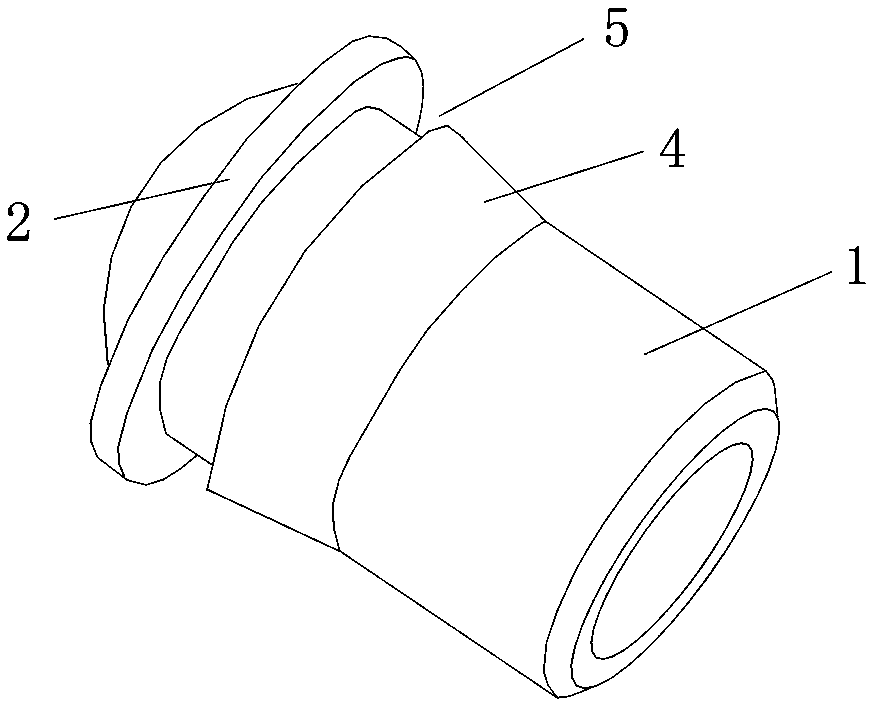

[0036] Such as Figure 1 to Figure 5As shown, the present invention provides a lamp bead lens for luminous road traffic signs, which includes a mounting rod 1 and a lens 2 fixed on the head end of the mounting rod 1. The mounting rod 1 is hollow to allow the luminous lamp bead 3 from The tail end of the installation rod 1 is inserted, the diameter of the lens 2 is greater than the diameter of the installation rod 1, and a circle of protruding guide stopper 4 is provided on the circumferential surface of the installer rod 1 to form a gap between the lens 2 and the guide stopper 4. A circle of clamping space 5, the guide limit part 4 is provided with a guide slope 41 inclined upward towards the direction of the lens 2, during installation, the installation rod 1 is inserted into the installation hole of the traffic sign from the front, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com