Backlight module, panel comprising same, and manufacturing method of backlight module

A technology of a backlight module and a manufacturing method, applied in optics, nonlinear optics, instruments, etc., can solve the problems of easy exposure of light-emitting diodes and failure to be protected, and achieve the effect of improving optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Various embodiments are proposed below for detailed description. The embodiments are only used as examples for illustration and will not limit the scope of protection of the present invention. The present invention can still be implemented using other features, components, methods and parameters. The embodiments are presented only to illustrate the technical features of the present invention, and are not intended to limit the patent scope of the present invention. Those skilled in the art will be able to make equivalent modifications and changes according to the descriptions in the following specification without departing from the spirit of the present invention.

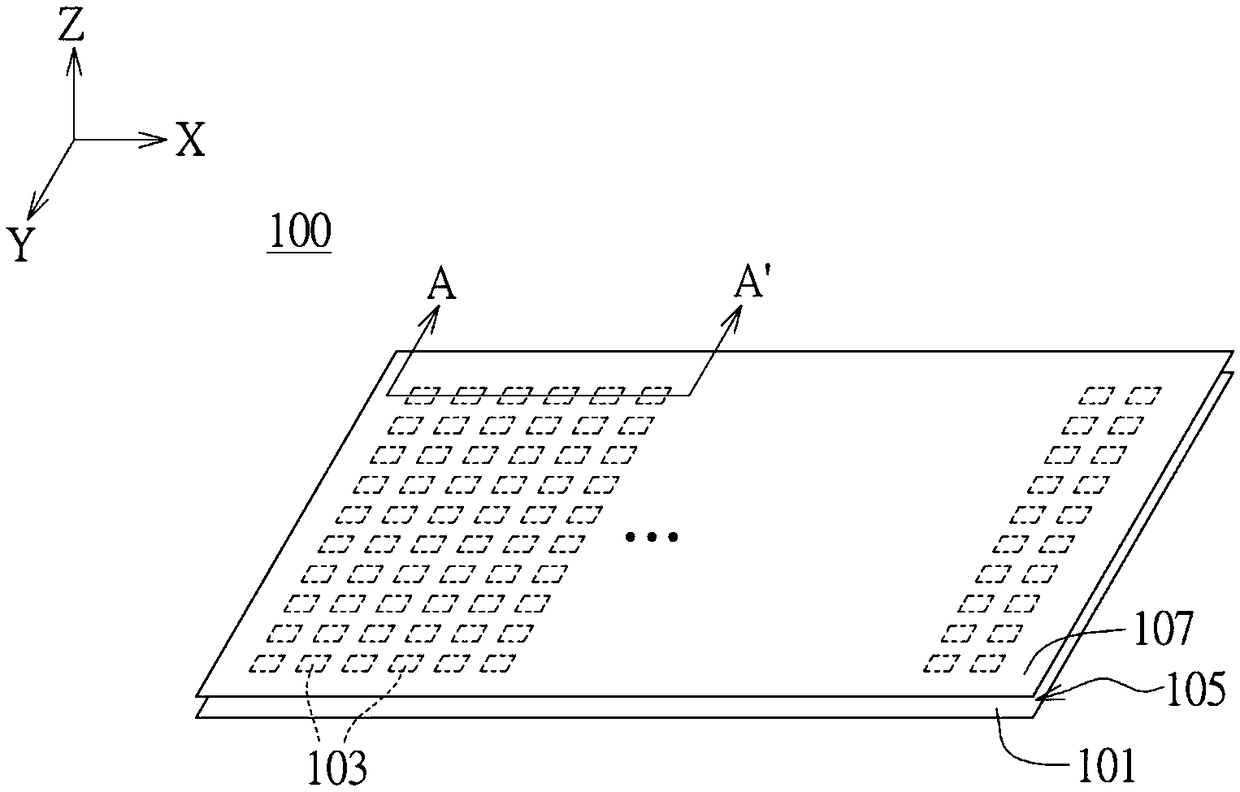

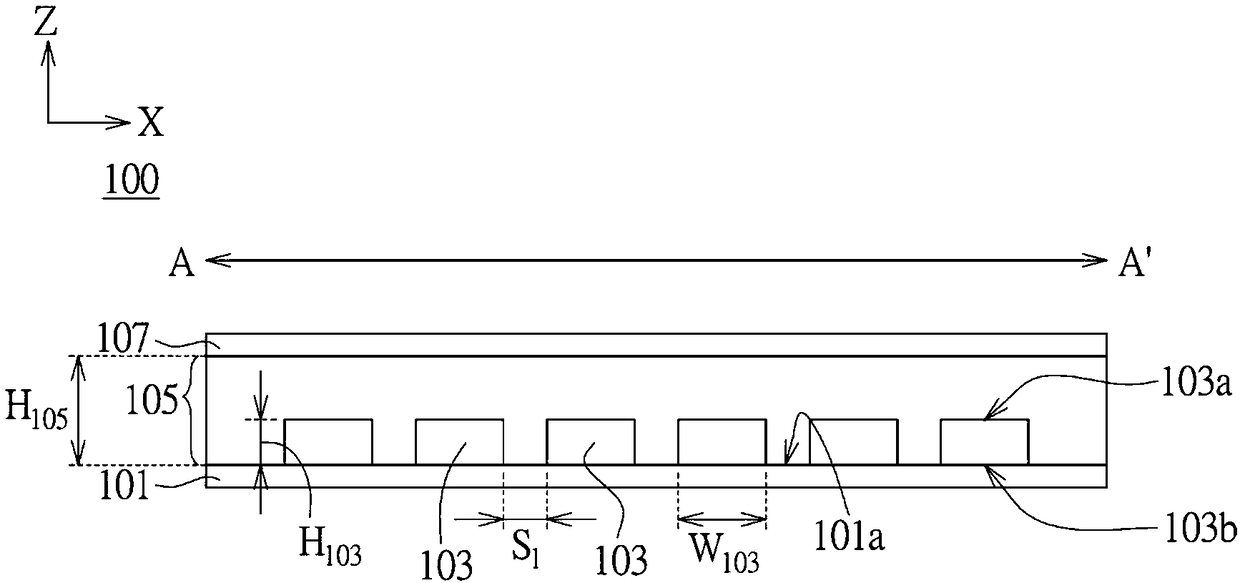

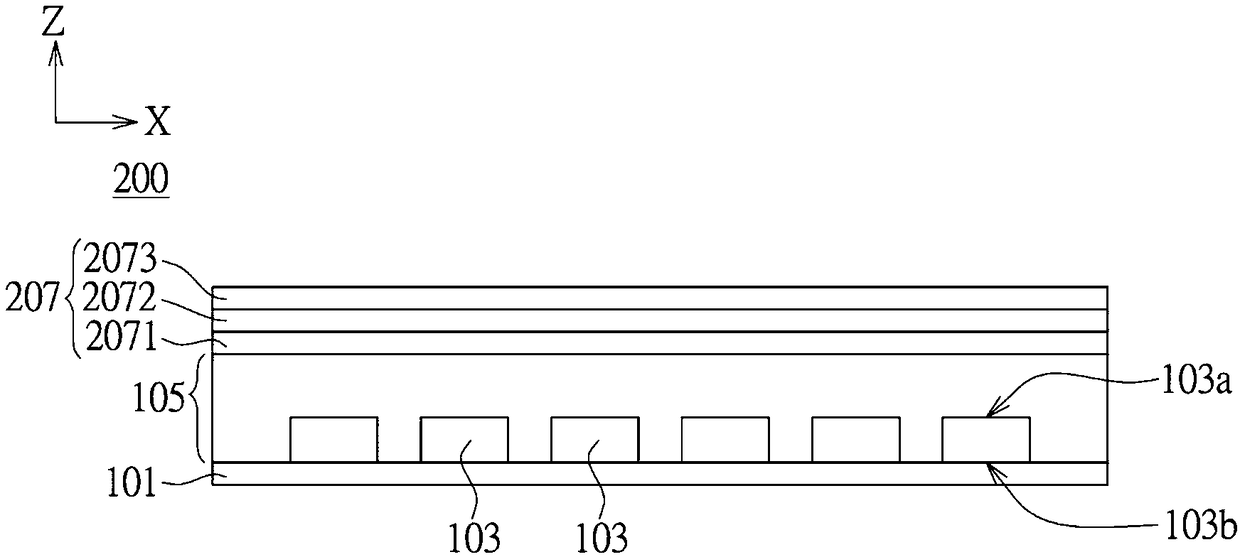

[0058] The light-emitting unit in the backlight module of the present invention is a light-emitting diode, and the light-emitting diode is a submillimeter light-emitting diode or a micro-light-emitting diode, and the size of the light-emitting diode is less than 500 microns, and an adhesive layer and an optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com