A cable laying method for vertically laying pipelines

A technology for laying pipelines and cables, which is applied in the direction of cable laying equipment, cable installation, cable installation devices, etc., can solve the problems of easy damage or damage, large maintenance and repair, heavy cable load, etc., to avoid damage or Effects of damage, power supply safety, and reduction of labor intensity and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a cable laying method for vertically laying pipelines includes the following steps:

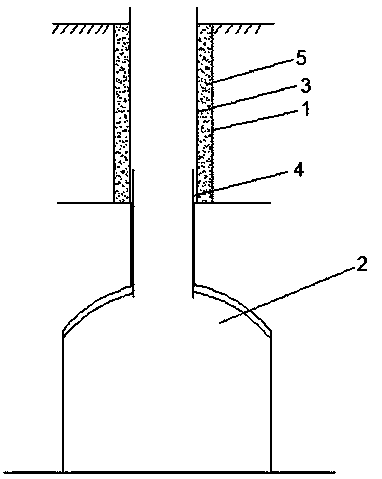

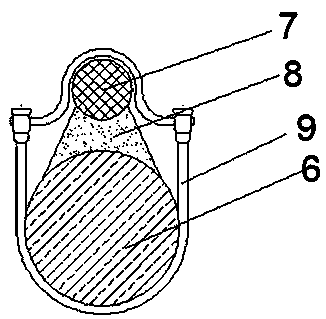

[0037]Step 1: Positioning and construction of the laying pipeline, the upper part of the laying pipeline is located in the area of electrical equipment 10m, the lower part communicates with the transportation avenue 2, and the laying pipeline is perpendicular to the transportation avenue 2; construct and lay the pipeline through the secondary hole forming method; 1) Construct the upper pipeline 3 (0-466m section), drill a large hole 1 (25-50cm) with a drilling rig, lift and weld several adjacent short seamless steel pipes (pipe wall thickness 12mm) in the large hole 1 Lower into the large hole 1, and form an annular gap 5 with a thickness of 5 cm between the inner wall of the large hole 1 and the upper pipe 3; 2) Inject the slurry in the annular gap 5 from the bottom of the upper pipe 3 to the ground; 3 ) After the grout is fixed, build the lower pipeline 4 (460-4...

Embodiment 2

[0046] In this embodiment, a cable laying method for vertically laying pipelines includes the following steps:

[0047] Step 1: Positioning and construction of the laying pipeline, the upper part of the laying pipeline is located in the area of electrical equipment 18m, the lower part communicates with the transportation avenue 2, and the laying pipeline is perpendicular to the transportation avenue 2; construct and lay the pipeline through the secondary hole forming method; 1) Construct the upper pipeline 3 (0-455m section), drill a large hole 1 (25-50cm) with a drilling rig, lift and weld several adjacent seamless steel short pipes (pipe wall thickness 8mm) in the large hole 1 Lower into the large hole 1, and an annular gap 5 with a thickness of 8 cm is formed between the inner wall of the large hole 1 and the upper pipe 3. In the annular gap 5, the slurry is injected in reverse from the bottom of the upper pipe 3 to the ground; 3) Wait for the slurry After fixing, build t...

Embodiment 3

[0057] In this embodiment, a cable laying method for vertically laying pipelines includes the following steps:

[0058] Step 1: Positioning and construction of the laying pipeline, the upper part of the laying pipeline is located in the area of electrical equipment 15m, the lower part communicates with the transportation avenue 2, and the laying pipeline is perpendicular to the transportation avenue 2; construct and lay the pipeline through the secondary hole forming method; 1) Construct the upper pipeline (0-466m section), drill a large hole 1 (25-50cm) with a drilling rig, lift and weld several adjacent short seamless steel pipes (pipe wall thickness 16mm) in the large hole 1, and lower it Into the large hole 1, an annular gap 5 with a thickness of 6cm is formed between the inner wall of the large hole 1 and the upper pipe 3; 2) Inject the slurry in the annular gap 5 from the bottom of the upper pipe 3 to the ground; 3) After the slurry is fixed, build the lower pipeline 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com