Automatic finish machining apparatus for step motor stators

A technology for stepping motors and stators, applied to chemical instruments and methods, cleaning methods using tools, cleaning methods and appliances, etc., can solve the problems of low efficiency of manual cleaning of stators, reduce defective rates and maintenance costs, and improve production Effect of efficiency and motor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

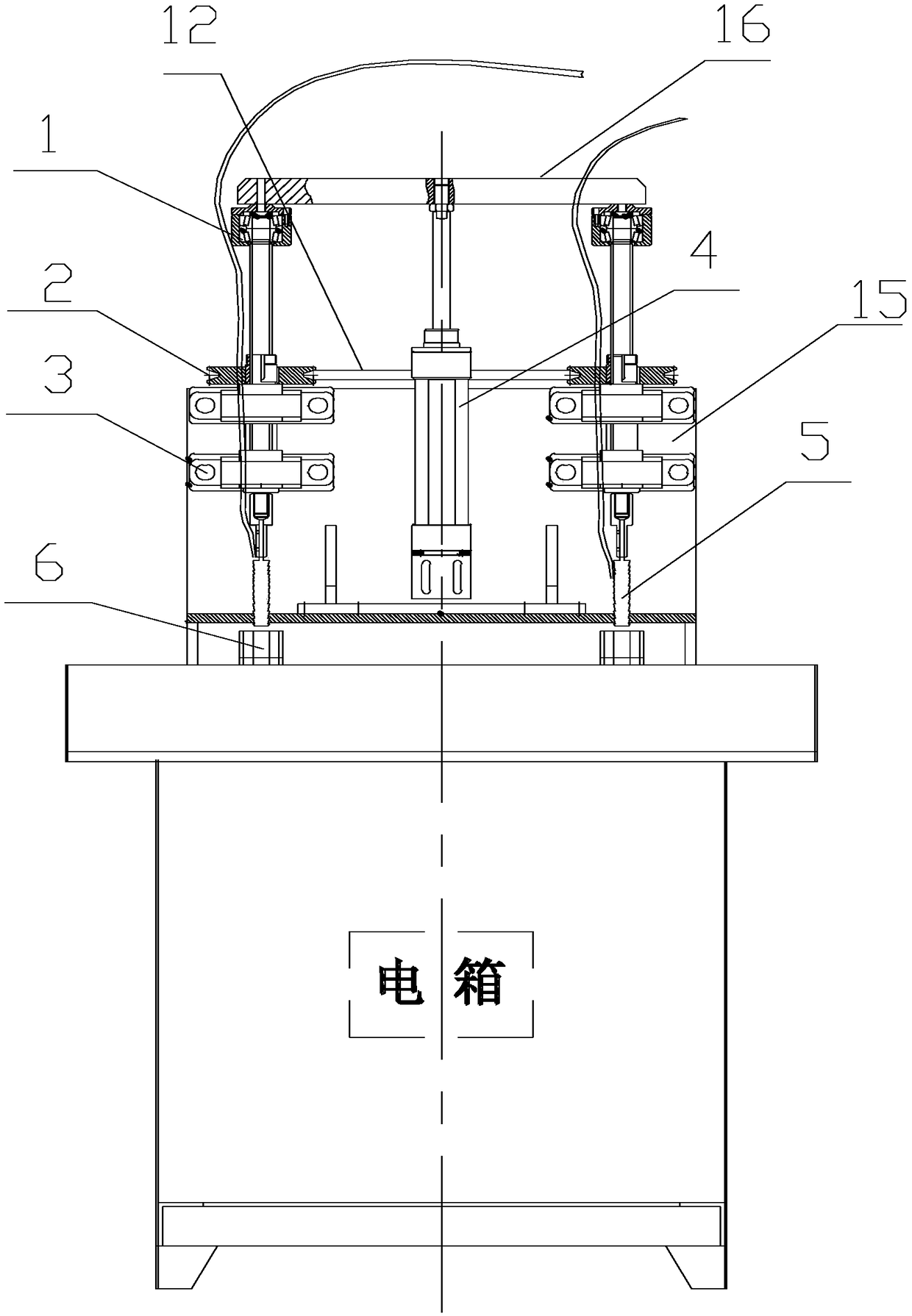

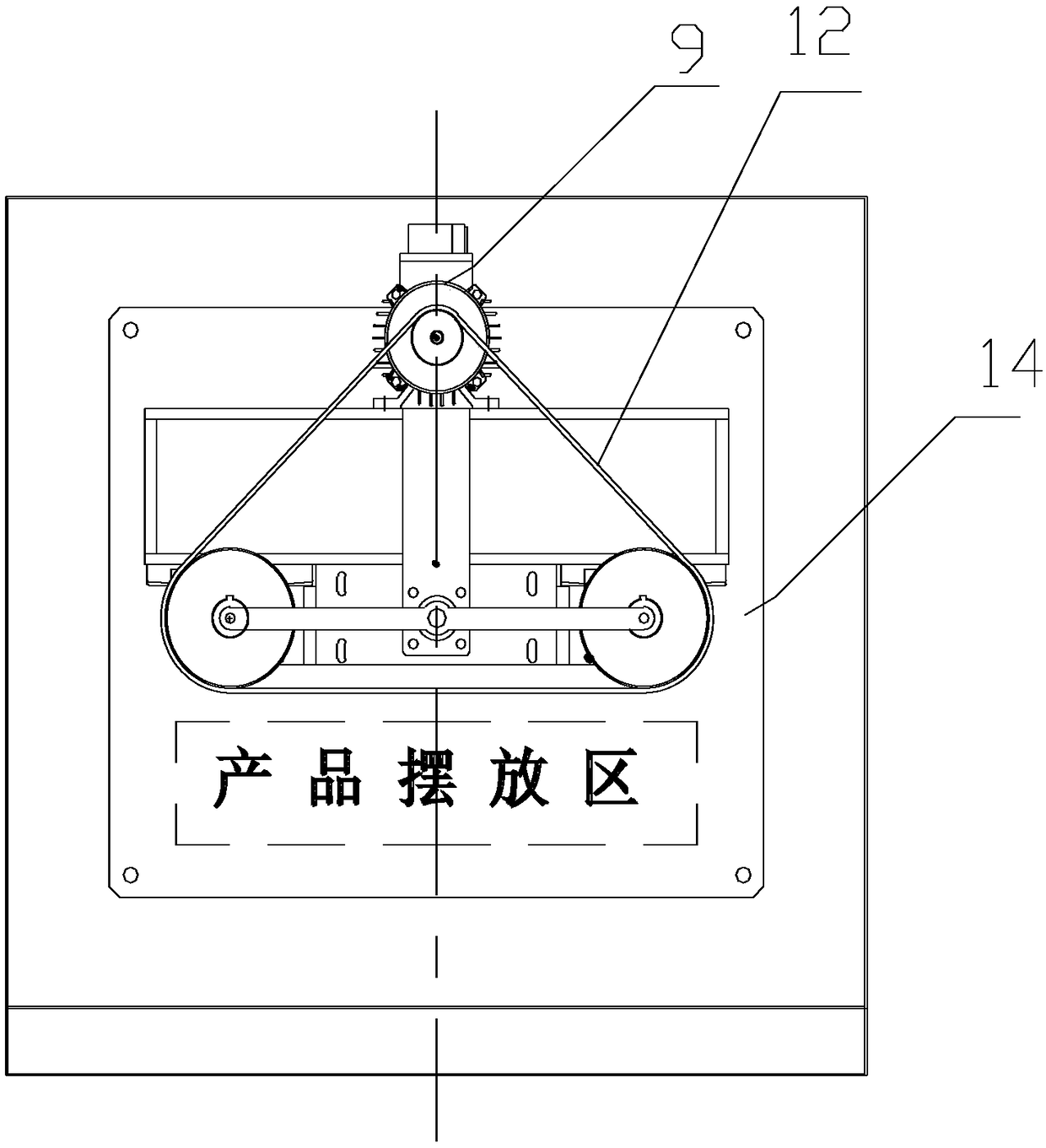

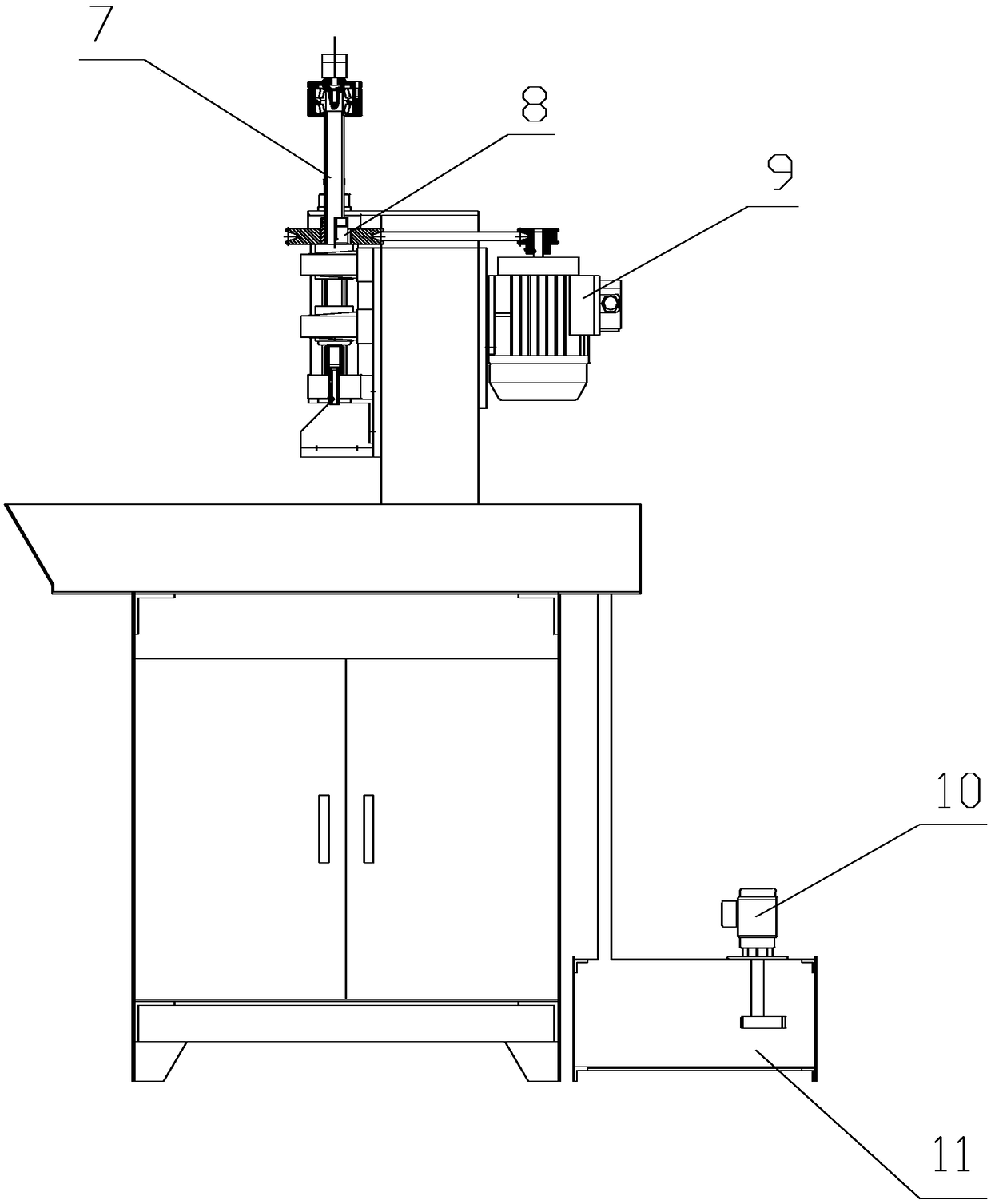

[0019] Such as Figure 1~4 , a stepper motor stator automatic finishing equipment, including a workbench, the table on the workbench is provided with a placement area for placing the stepper motor stator 6, a mounting frame 15 is fixed on the workbench, and the mounting frame 15 is provided with There is an up and down lifting device, and the lifting device is provided with a brush 5 for cleaning the stator 6 of the stepping motor. A water outlet is provided, a water tank 14 is provided on the workbench, and a water tank 11 communicated with the water tank 14 is provided below the workbench.

[0020] The lifting device includes a cylinder 4 fixed on the mounting frame 15, a mounting plate 16 is fixed on the piston rod of the cylinder 4, and a rotating shaft assembly is connected to the mounting plate 16. The two ends of the rotating shaft assembly are round shafts, and the middle is an involute spline 7. The brush 5 is fixed on the lower end of the rotating shaft assembly. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com