A dry sludge conveying system and device thereof

A technology of conveying device and conveying system, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of reducing the service life of the pump, making the feeding hopper dirty, and polluting the surrounding environment, so as to prolong the service life and occupy an area The effect of reducing the area and ensuring environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

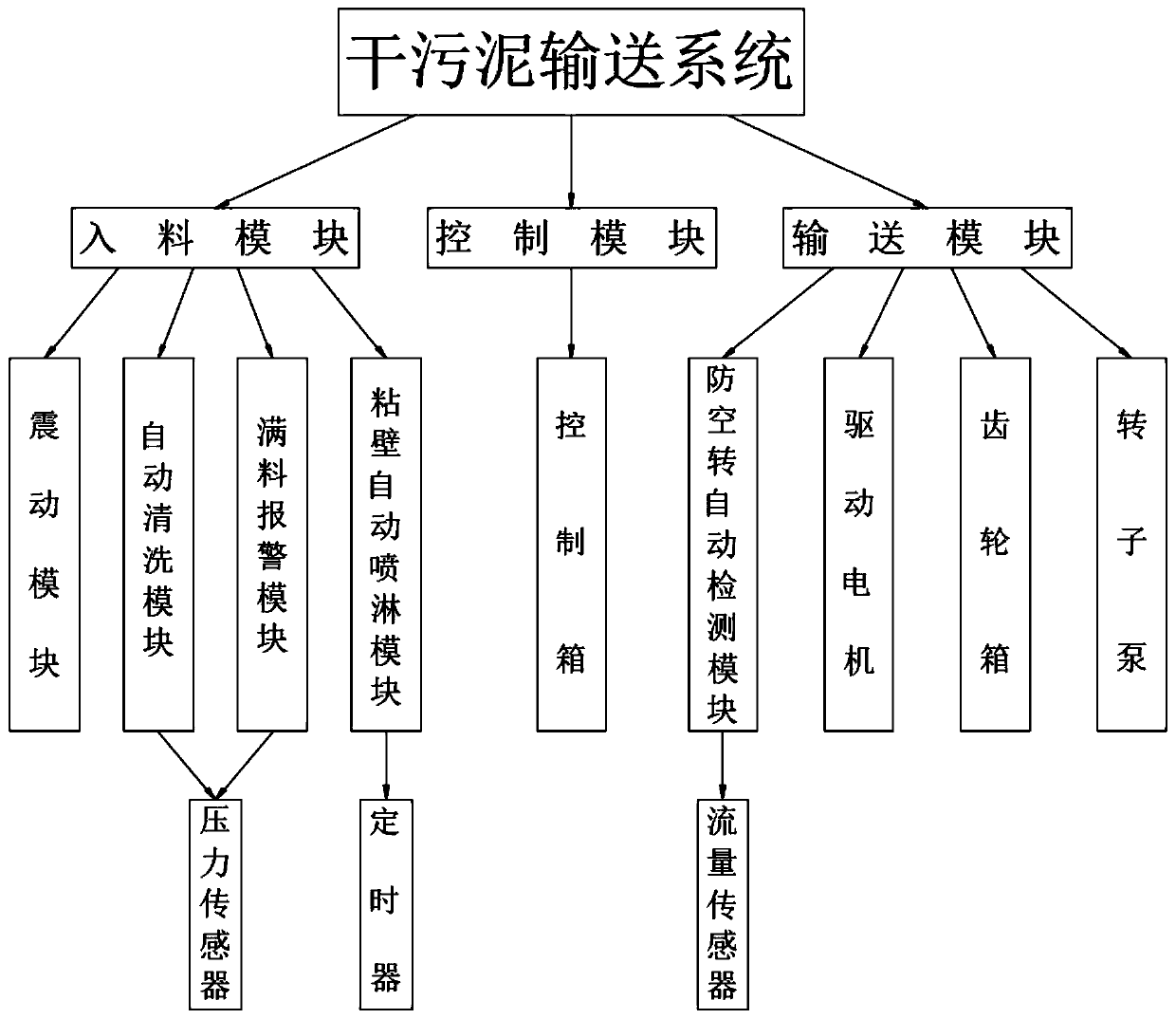

[0025] Embodiment 1: as figure 1 As shown, the present invention provides a technical solution, a dry sludge conveying system, including a control module, a feeding module and a conveying module. The control module includes a control box, and a controller, an alarm and a control switch are installed inside the control box. The model of the controller is S7-200PLC. As the core of the whole system, the controller receives signals from various sensors and sends relevant instructions according to the signals. power supply.

[0026] According to the above technical scheme, the feeding module includes a vibration module, an automatic cleaning module, a sticky wall automatic spray module and a full material alarm module. The vibration module includes an electromagnet, a slider and a magnet. The outer side slides back and forth to generate vibration. The automatic cleaning module includes a pressure sensor. The pressure signal received by the pressure sensor changes from large to sma...

Embodiment 2

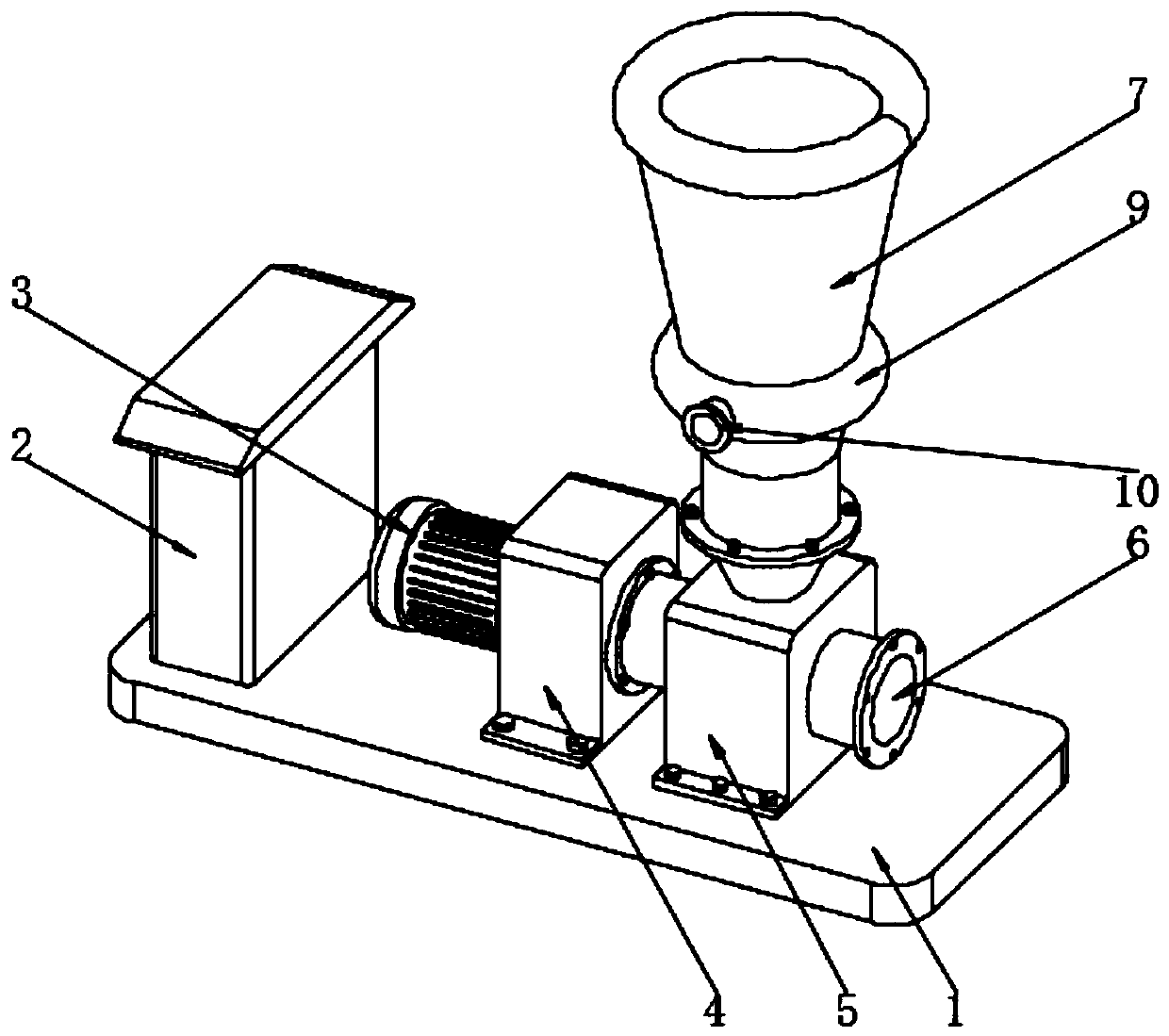

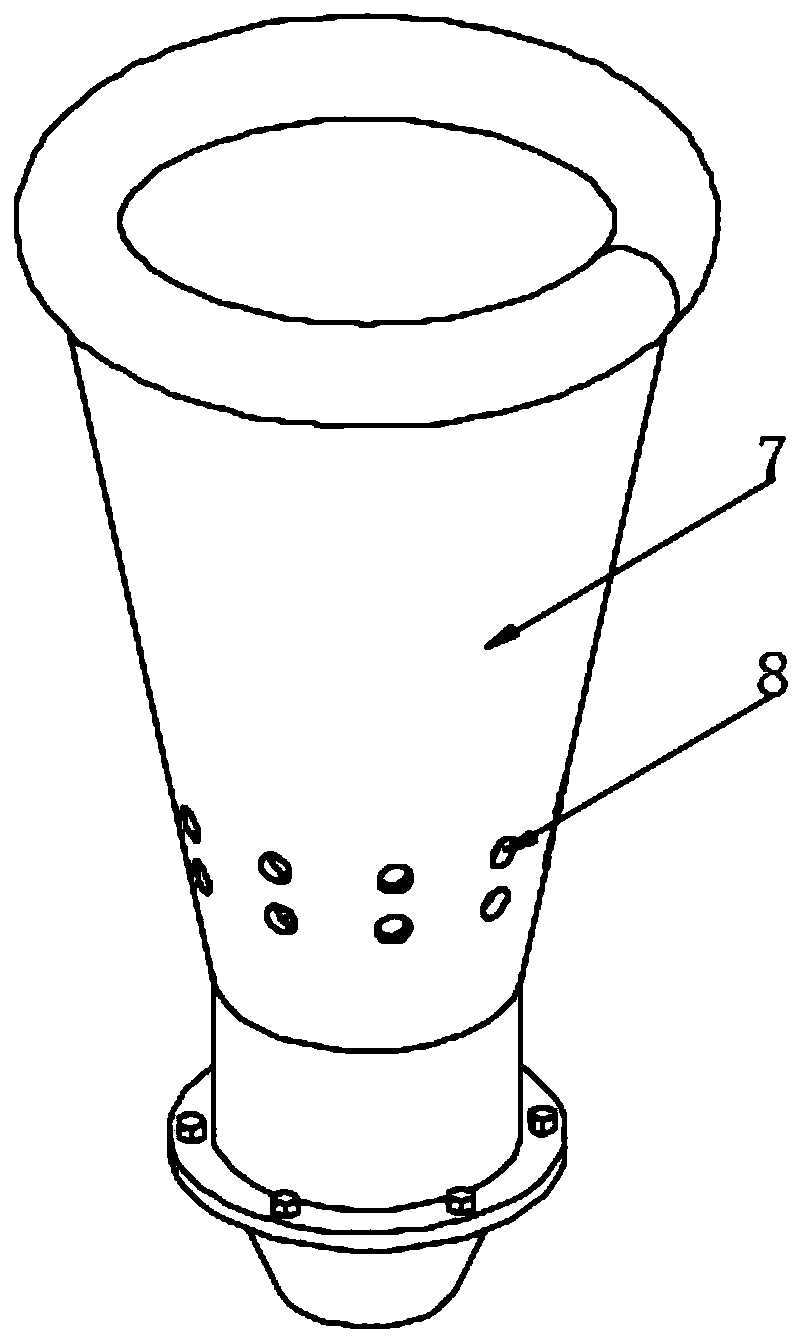

[0028] Embodiment 2: as Figure 2-5 As shown, the present invention provides a technical solution, a dry sludge conveying device, including a bottom plate 1, in order to prevent the bottom plate 1 from slipping during use, the bottom surface of the bottom plate 1 is attached with a non-slip rubber pad, the bottom plate 1 The control box 2 is installed on one end of the upper surface, the gear box 4 is fixed on the upper middle part of the bottom plate 1 through fixing screws, and the driving motor 3 is fixed on one side of the gear box 4 through fixing screws. The model of the driving motor 3 is Y80M1-2. 4 The rotor pump 5 is fixedly installed on the other side by fixing screws. In order to prevent the leakage of dry sludge between the rotor pump 5 and the feeding hopper 7, a seal is embedded between the rotor pump 5 and the feeding hopper 7. A rubber ring, a dry sludge delivery port 6 is provided on one side of the rotor pump 5, a feeding hopper 7 is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com