Preparation method and application of a conductive hydrogel capable of sustained release of drugs and factors

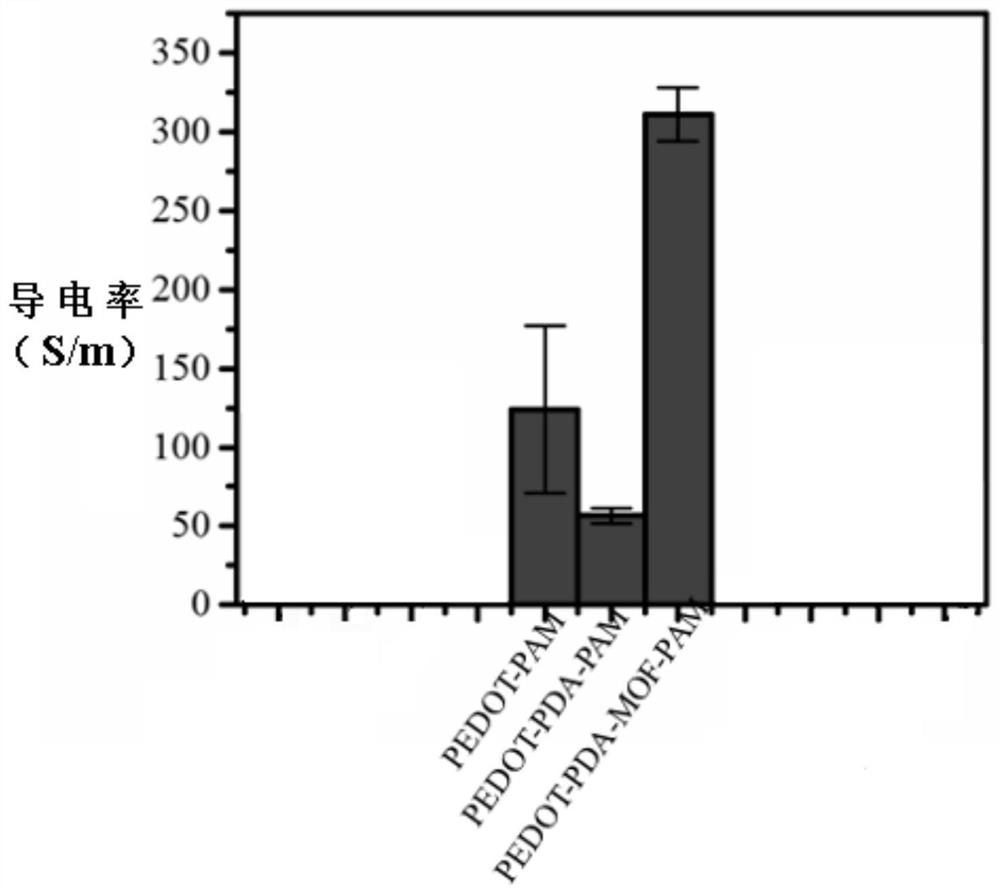

A conductive hydrogel and slow-release drug technology, applied in drug delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as shortening the electron transfer process, limiting applications, and low drug concentration in lesion parts, achieving Increase the effect of immobilized bioactive growth factors, stabilize metal organic framework structure, and improve electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the conductive hydrogel capable of sustained release of medicines and factors comprises the following steps:

[0028] Step 1: Prepare a conductive polymer monomer solution with a mass concentration of 0.04-2%, add an oxidizing agent, stir and react at 0-5°C for 4-10 days, perform centrifugal cleaning several times after sufficient reaction, and obtain a conductive polymer polymer material; the mass ratio of the conductive polymer monomer to the oxidizing agent is 1:1~20; the oxidizing agent is one of ferric chloride, ferric nitrate, ferric sulfate and ammonium ferric sulfate; the conductive polymer monomer is pyrrole monomer, One of aniline monomers, thiophene monomers and 5-carboxyindole monomers.

[0029] Step 2: Prepare a dopamine aqueous solution with a concentration of 0.05-10 mg / mL, adjust the pH to 8-13 with ammonia water or trisaminomethane buffer solution; add the conductive polymer obtained in step 1, and stir at room temperature for ...

Embodiment 1

[0039] A preparation method of conductive hydrogel, comprising the following steps:

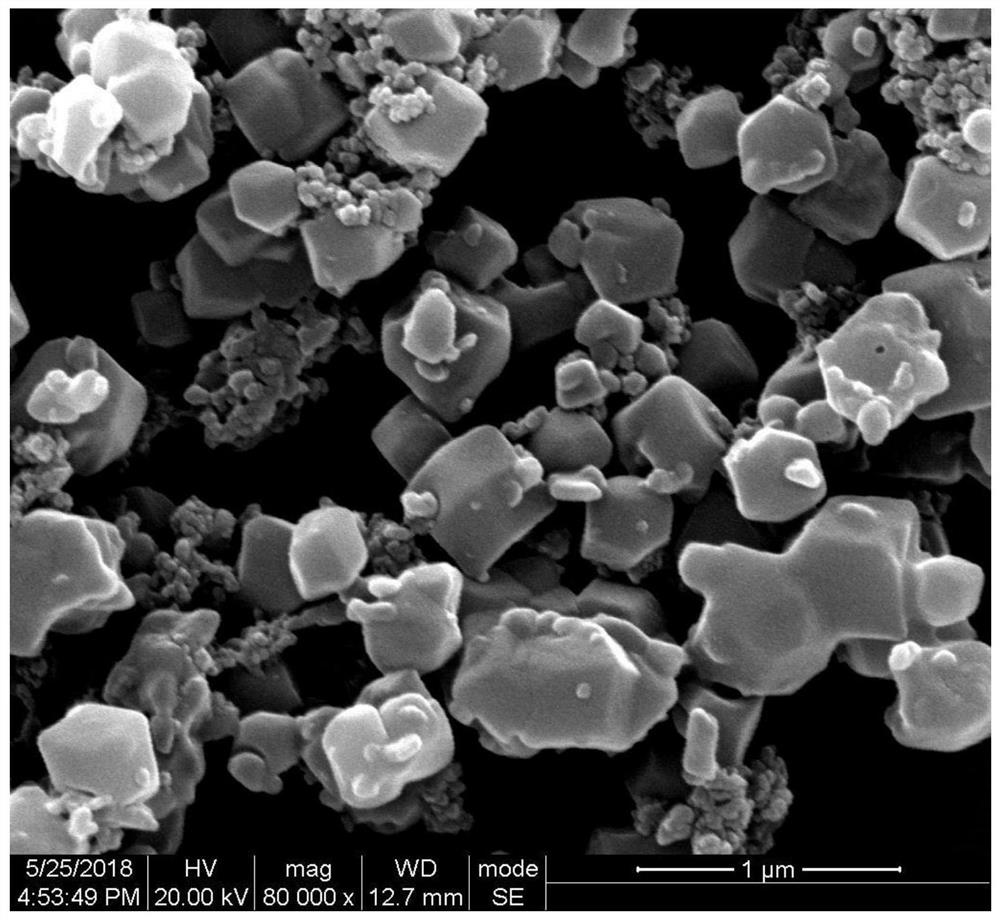

[0040] A, preparation of polydopamine / poly 3,4-ethylenedioxythiophene complex

[0041]Dissolve 266 μL of 3,4-ethylenedioxythiophene monomer in 30 mL of absolute ethanol to obtain a solution with a mass concentration of 1.5% of 3,4-ethylenedioxythiophene monomer; add 7 g of trichloride to the above solution iron, stirred and reacted at 0-5°C for 5 days; the solution after the above reaction was centrifuged and washed several times with deionized water to obtain poly-3,4-ethylenedioxythiophene particles; dopamine was dissolved in deionized water to obtain A dopamine solution with a concentration of 0.5 mg / mL, the pH of the above solution was adjusted to 8.5 with ammonia water; then, poly-3,4-ethylenedioxythiophene particles were added to the above solution, stirred at room temperature for 12 hours, and washed several times to obtain poly Dopamine / poly-3,4-ethylenedioxythiophene complex.

[00...

Embodiment 2

[0050] A, preparation of polydopamine / polypyrrole complex

[0051] Dissolve 190 μL of pyrrole monomer in 40 mL of absolute ethanol to obtain a solution with a mass concentration of 0.58% pyrrole monomer; add 5 g of iron sulfate to the above solution, and stir and react at 0-5°C for 3 days; The final solution was centrifuged and washed 3 times with deionized water to obtain polypyrrole particles; dopamine was dissolved in deionized water to obtain a solution with a dopamine concentration of 0.4 mg / mL, and the pH of the above solution was adjusted to 8.5 with trisaminomethane buffer. ; Then, add polypyrrole particles to the above solution, stir at room temperature for 12 hours, and wash several times to obtain a polydopamine / polypyrrole complex.

[0052] B, Preparation of ZIF-7 / polydopamine / polypyrrole complex

[0053] Dissolve zinc acetate in N,N-dimethylformamide to obtain a solution with a mass concentration of zinc acetate of 2.15%; dissolve benzimidazole in methanol to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com