Network nozzle pressure detection device

A network nozzle and detection device technology, applied in textiles and papermaking, etc., can solve the problem of inaccurate display of network nozzle pressure, etc., achieve the effect of simple structure, strong practicability, and enhanced product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The network nozzle pressure detection device of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

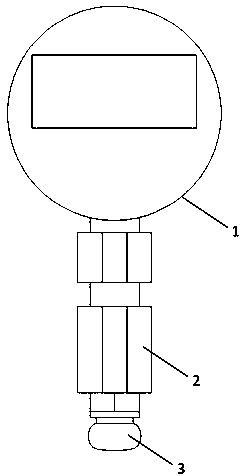

[0023] Such as Figure 1~4 As shown, a network nozzle pressure detection device includes an electronic pressure gauge 1, a reducing sleeve 2 and a quick plug 3 that are threaded sequentially from top to bottom;

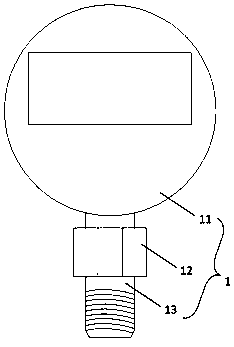

[0024] The electronic pressure gauge 1 is composed of a pressure gauge plate 11, a connecting nut 12 and a connecting stud 13 sequentially connected from top to bottom, and the outer circumference of the connecting stud 13 forms a thread;

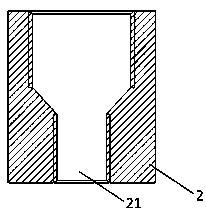

[0025] A stepped hole 21 is formed in the middle of the reducing sleeve 2;

[0026] The quick plug 3 is composed of a stud 31, a stud 32 and a connector 32 connected sequentially from top to bottom;

[0027] The connection head 32 is connected to the network nozzle.

[0028] The aperture of the upper hole of the stepped hole 21 is greater than the ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com